-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

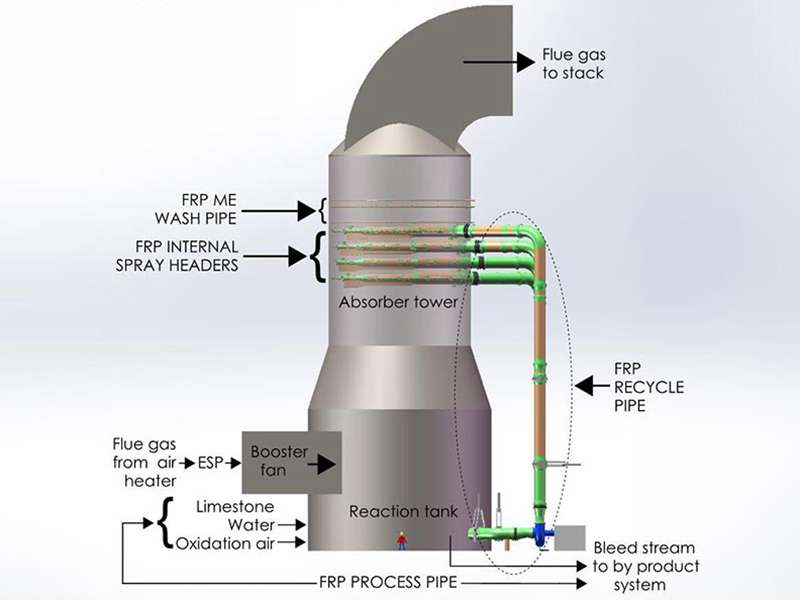

Scrubbers

Fiberglass scrubbers are very popular for liquid storage, water treatment, FGD system, chemical processing and pollution control, the gas cleaning process, controlling gaseous emissions, especially polluted gases, waste incineration and power generation processes. Because:

In comparison to metal or rubber-lined steel products, Fiberglass reinforced plastic (FRP) have many advantages.

FRP is very light-weight, very strong and can be produced in a wide range of diameters, which has a direct impact in terms of extending the installation’s lifespan and cost saving.

In addition, FRP is a durable choice of materials compared to traditional materials, which means that FRP delivers significant benefits in terms of resistance to abrasion, chemical corrosion, rust, as well as to extremely low and extremely high temperatures. This makes it a long-lasting solution with low maintenance costs for clients.

The inside of fiberglass scrubbers are smooth, giving excellent flow characteristics and are easy to clean.

Supplemental system components including internal and external piping, spray banks, support beams, mist filters, packing, distribution systems and ducting can be fabricated in virtually any shape or configuration.

The exterior accessories such as ladders, platforms, railing, walkway, drainage, electrostatic discharge are also Jrain’s supply scope.

Jrain analyzes each new project and reviews the system performance specifications in order to select the right materials and construction methods, and finally designs and fabricates the fiberglass scrubbers based on requirements regarding medium, temperature, flow rate, pressure, earthquake, wind load and climate conditions.

When necessary, ECR glass fiber is used in addition to E-glass fiber in order to create higher chemical resistance, and a colored or semi-transparent top coat is used to resist UV light and provides protection.

As a full service supplier, Jrain designs, produces and installs equipment for the exterior of a scrubber such as ladder, platforms, drainage, protection liner and electrostatic discharge but also has the facility to serve you by delivering all internals such as spray banks, support beams, mist filters and packing.