-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

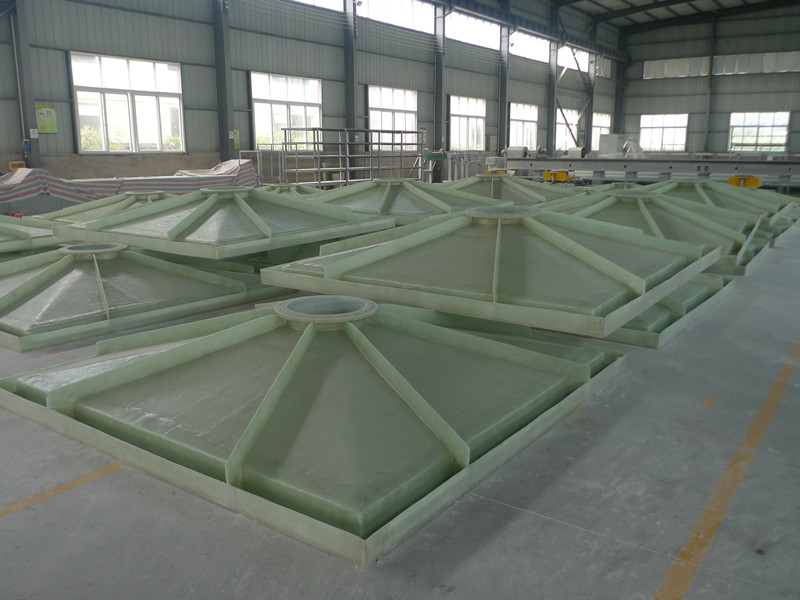

Covers

Fiberglass covers are widely used in water and sewage treatment, chemical and petroleum, food, pharmacy, etc.

Fiberglass covers are different in colors and shapes such as round, rectangular, arch, flat, house type, etc. as per customer’s requirements.

Fiberglass covers are always designed to meet a wide range of temperature, the outer surface finish is remarkable resistant to harsh environmental conditions, making fiberglass an ideal material for exposure to the elements, including the sun, snow and even the salt-laden atmosphere found close to the coastlines. The wind and seismic parameters are also be consider for the structure calculation. Finite Element Analysis (FEA) can also be used to optimize the design even further.

Fiberglass covers and hoods are featured by:

1. Good insulation: because of low thermal conductivity coefficient, fiberglass cover can meet the common insulation requirement without additional insulation structure.

2. Light weight and high strength. The weight of fiberglass product is only 1/3~1/4 of steel.

3. Easy installation and low maintenance charge

4. Covers can be designed and manufactured by small pieces for easy handling and transportation

5. Excellent corrosion resistance: different resins can be chosen for different conditions.

6. Long service life

Jrain designs and manufactures various fiberglass covers for different environments, and the sizes are ranging from small to big.

For big covers made by different sections, we preassemble them at our workshop to ensure that each section will match with the others.

We have special mold department to ensure all molds that we use are qualified, which can guarantee the finished products meet the requirements.