the importance of frp launder in modern water treatment

Furthermore, fire retardant fiberglass is lightweight and easy to install, making it a practical choice for a wide range of applications

fire retardant fiberglass. Its flexibility allows it to be easily shaped and cut to fit specific requirements, making it ideal for custom installations in tight spaces or unusual shapes.

Since they don't rely on electricity, there's a reduced risk of electrical accidents, making them suitable for areas with flammable substances Since they don't rely on electricity, there's a reduced risk of electrical accidents, making them suitable for areas with flammable substances

Since they don't rely on electricity, there's a reduced risk of electrical accidents, making them suitable for areas with flammable substances Since they don't rely on electricity, there's a reduced risk of electrical accidents, making them suitable for areas with flammable substances pneumatic drilling machine. The use of compressed air also eliminates the need for lubricants, reducing the risk of fires and explosions in hazardous locations.

pneumatic drilling machine. The use of compressed air also eliminates the need for lubricants, reducing the risk of fires and explosions in hazardous locations.

They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners

They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners They can be cut to size using standard tools and hardware, and can be attached to a variety of surfaces using screws, nails, or other fasteners

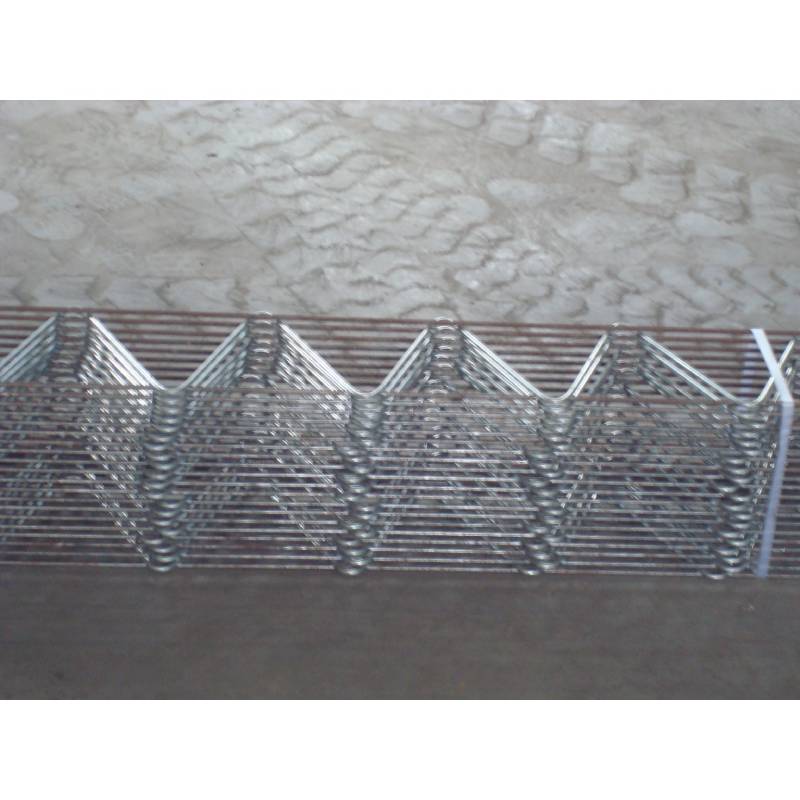

Depending on your location and potential threats, you'll need a fence that can withstand animal pressure Depending on your location and potential threats, you'll need a fence that can withstand animal pressure

Depending on your location and potential threats, you'll need a fence that can withstand animal pressure Depending on your location and potential threats, you'll need a fence that can withstand animal pressure It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens

It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens