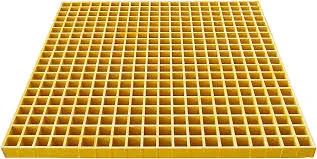

Hengshui Jrain Frp fiberglass floor grating

However, these machines require a reliable source of compressed air, often provided by a compressor on site. The maintenance of both the drill and the compressor is critical for optimal performance and to prevent potential breakdowns. Regular cleaning and inspection, along with timely replacement of worn parts, are essential practices to ensure the longevity and efficiency of the pneumatic drilling machine.

When it comes to installation, fiberglass pipe insulation fittings are designed for ease of use fiberglass pipe insulation fittings. They are available in pre-cut sections and can be tailored to fit a variety of pipe diameters and shapes. The flexibility of the material allows for quick and secure attachment without the need for specialized tools or complex procedures. This user-friendly aspect not only speeds up installation processes but also reduces labor costs associated with more complicated insulation solutions.

fiberglass pipe insulation fittings. They are available in pre-cut sections and can be tailored to fit a variety of pipe diameters and shapes. The flexibility of the material allows for quick and secure attachment without the need for specialized tools or complex procedures. This user-friendly aspect not only speeds up installation processes but also reduces labor costs associated with more complicated insulation solutions.

Furthermore, tunnel bench drilling bits are designed to minimize vibration and noise during drilling. This helps to create a safer and more comfortable working environment for operators, reducing the risk of injuries and improving overall productivity.

Furthermore, retrac bits are easy to maintain. They can be quickly disassembled for cleaning and maintenance, ensuring that they stay in top condition for longer. This reduces downtime and increases the overall productivity of the drilling operation.

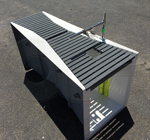

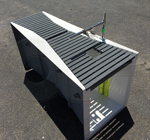

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.