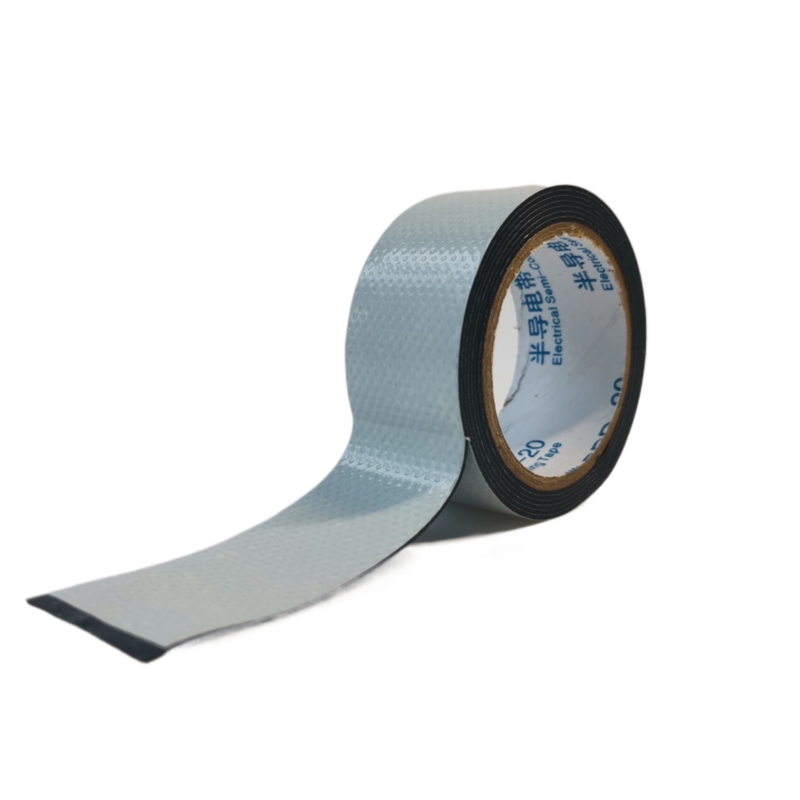

High Voltage Busbar Insulation Tape Essential for Safety and Efficiency

Code: XF-KJD

This modular structure makes it easier to maintain and scale applications over time, as individual components can be replaced or updated without affecting the entire system This modular structure makes it easier to maintain and scale applications over time, as individual components can be replaced or updated without affecting the entire system

This modular structure makes it easier to maintain and scale applications over time, as individual components can be replaced or updated without affecting the entire system This modular structure makes it easier to maintain and scale applications over time, as individual components can be replaced or updated without affecting the entire system frp pipeline.

frp pipeline. Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces

Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces Its adjustable power settings also enable operators to control the intensity of the impact, ensuring safety and preventing damage to surrounding surfaces small air jack hammer.

small air jack hammer.

If you’re wondering which tape should you buy, consider self-adhesive butyl tape. It’s much easier to install, meaning no fiddly application and less chance of getting yourself stuck.

5. Easy Installation Installation of butyl rubber roofing sheets is relatively straightforward, which can lead to reduced labor costs and faster project completion times. The sheets can be adhered using various methods, including adhesives and mechanical fasteners, allowing for flexibility in installation techniques based on project requirements.

As mentioned, different colors indicate different types of electrical tape features. Many standard electrical tapes are sold in black, but you can find them in nearly every color. Choose the color of tape based on the application you will be using it for and its voltage, phase, and other electric-relevant information.

Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating

Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating Electrical Insulation Fire-resistant adhesive tape can be used to insulate electrical wires and cables to prevent short circuits and fires caused by overheating fire resistant adhesive tape.

fire resistant adhesive tape.Understanding 3M HT Insulation Tape A Versatile Solution for Various Applications

One of the key advantages of using 130C linerless rubber splicing tape is its ability to provide a tight and secure seal. This makes it perfect for applications where a leak-proof bond is essential, such as in plumbing or automotive industries. The tape is also resistant to chemicals and oils, further enhancing its durability and reliability.

Fire-resistant electrical tape is typically made from durable materials such as PVC (polyvinyl chloride), which can endure higher temperatures than standard tapes. These tapes are coated with flame-retardant compounds that significantly reduce the risk of ignition when exposed to heat or flames. Some products may also have a backing made of fiberglass or other inherently flame-resistant materials, adding an extra layer of protection.

The core function of PVC insulation tape is to provide electrical insulation, preventing short circuits, and protecting wires and connections from environmental factors. Its high elasticity allows it to stretch and conform to a variety of shapes, making it ideal for wrapping around wires, cables, and other electrical components.

High Voltage Busbar Insulation Tape Essential for Safety and Efficiency

Code: XF-KJD

door seal with rubber strip. The flexibility of the material allows it to adapt to various door frames, ensuring a snug fit that does not compromise door operation. Moreover, rubber strips come in different sizes and thicknesses, allowing homeowners to choose the option that best fits their specific needs and aesthetic preferences.

door seal with rubber strip. The flexibility of the material allows it to adapt to various door frames, ensuring a snug fit that does not compromise door operation. Moreover, rubber strips come in different sizes and thicknesses, allowing homeowners to choose the option that best fits their specific needs and aesthetic preferences.4. Press the tape firmly against the surface to ensure full contact between the tape and the substrate.Smooth out any wrinkles, bubbles, or gaps to create a tight seal. In some cases, you might need to apply multiple layers of tape, particularly when sealing larger gaps or joints.

For applications that require a higher level of water resistance or waterproofing, specialized tapes or additional measures may be necessary. It’s recommended to assess the specific requirements of your application and consider the expected level of water exposure to determine whether polyethylene tape alone provides sufficient water resistance or if additional waterproofing measures are necessary.

It’s common for well control box installers to carry multi-purpose control boxes with them so they can install one at any job site. This sometimes results in the consumer paying more for something they don’t need.

If you have any questions, don't hesitate to reach out. We'll do what we can to help.