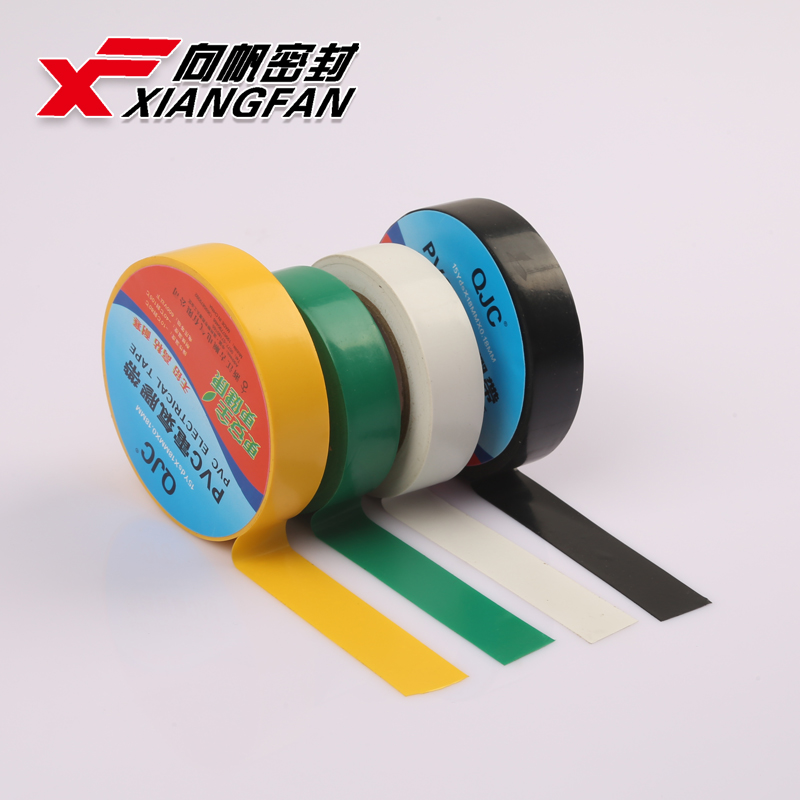

- The production process of PVC electrical tape involves a combination of science and art. Raw materials, primarily PVC resin, plasticizers, stabilizers, and adhesives, are compounded and then processed through extrusion and coating techniques. The tape is then wound onto rolls and undergoes quality control checks to ensure compliance with international standards such as UL, CSA, and RoHS.

These boxes aren’t one-size-fits-all. They come tailor-made to suit specific environments and applications, ensuring that they’re up to the task, whether on a factory floor or in an outdoor setting.

For instance, it can be used to outline the boundaries of wet floors, slippery surfaces, or areas where flammable substances are stored For instance, it can be used to outline the boundaries of wet floors, slippery surfaces, or areas where flammable substances are stored

For instance, it can be used to outline the boundaries of wet floors, slippery surfaces, or areas where flammable substances are stored For instance, it can be used to outline the boundaries of wet floors, slippery surfaces, or areas where flammable substances are stored red and white floor marking tape. By clearly indicating these risks, the tape helps to prevent accidents and injuries before they occur.

red and white floor marking tape. By clearly indicating these risks, the tape helps to prevent accidents and injuries before they occur.Electrical wiring and phasing tasks call for a specific type of tape – electrical tape – in order to safely get the job done. But what exactly is it that makes electrical tapes so different from duct tapes, polyethylene film tapes, and others?

Self-fusing tape is a versatile and useful product that has a wide range of applications. Self-fusing tape is a type of tape that fuses to itself when applied, creating a strong and durable bond. This type of tape is typically made from silicone, which gives it unique properties that make it ideal for a variety of uses.

CONCLUSION

yellow warehouse floor tape. Unlike paint, which can be messy and time-consuming to apply, tape can be easily installed and removed as needed. This makes it a flexible option for businesses that may need to modify their floor markings frequently.