There are various types of rock drill shank adapters, each tailored to specific drilling applications and conditions rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.

rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.

...

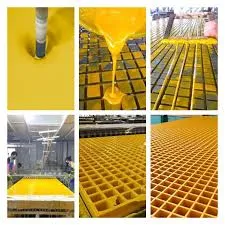

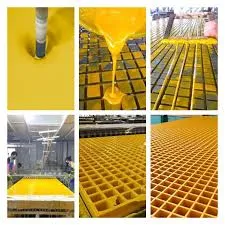

Additionally, fiberglass stair treads are easy to clean and maintain fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

...

...

...

![Two Two]()

...

...

Another benefit of FRP stair treads is their lightweight nature, which makes them easy to install and transport

frp stair tread. This is especially advantageous in applications where heavy materials are not feasible or practical. The lightweight properties of FRP treads also make them a cost-effective option, as they can be easily handled by one person and do not require heavy machinery for installation.

...

...

...

...

In addition to the materials used in their construction, vessels and tanks must also be designed with features that ensure the safety and efficiency of their operation Impact drill bits come in various types, each tailored to specific applications. Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic

Impact drill bits come in various types, each tailored to specific applications. Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic

Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic impact drill bits. Masonry bits, with their carbide tips, excel at drilling through brick, concrete, and other masonry materials. Meanwhile, screw-driving bits are designed to work seamlessly with screws, simplifying the process of fastening and unfastening.

impact drill bits. Masonry bits, with their carbide tips, excel at drilling through brick, concrete, and other masonry materials. Meanwhile, screw-driving bits are designed to work seamlessly with screws, simplifying the process of fastening and unfastening.

rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.

rock drill shank adapter. For instance, spline shank adapters are commonly used in heavy-duty drilling due to their robust design and increased torque transmission. Meanwhile, hexagonal shank adapters, with their six-sided profile, offer better stability and resistance to torsion. Additionally, there are adapters designed for use with DTH (Down-the-Hole) hammers, which are specifically engineered for deep hole drilling.

The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children

The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children The smooth surface of FRP equipment reduces the risk of splinters and sharp edges, providing a safer playing environment for children

Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic

Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic