...

2025-08-14 08:37

2302

...

2025-08-14 08:36

1521

...

2025-08-14 08:23

972

...

2025-08-14 08:17

2174

...

2025-08-14 07:15

2203

...

2025-08-14 07:05

215

...

2025-08-14 07:01

2406

...

2025-08-14 06:47

1386

...

2025-08-14 06:22

1463

...

2025-08-14 06:00

521

Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges

Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating

Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating

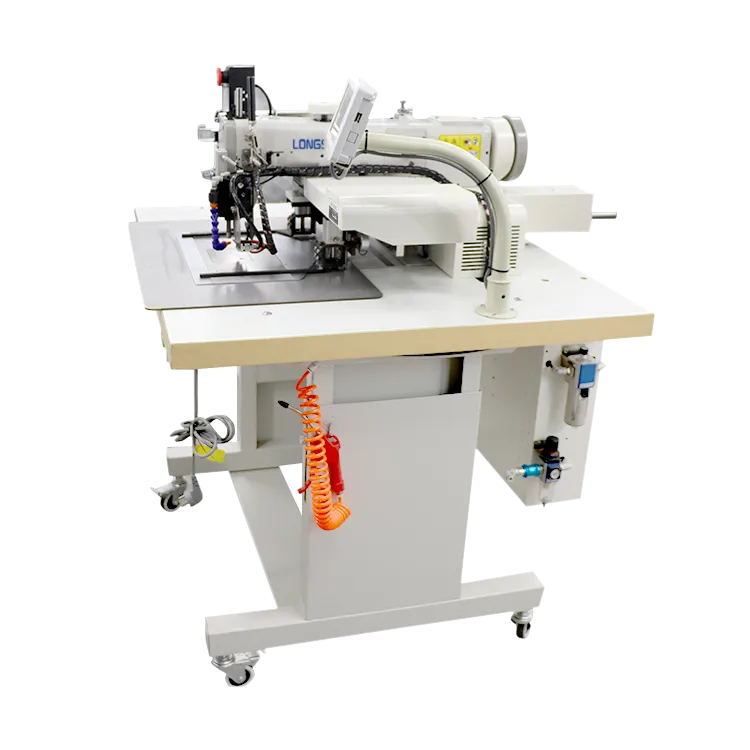

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly