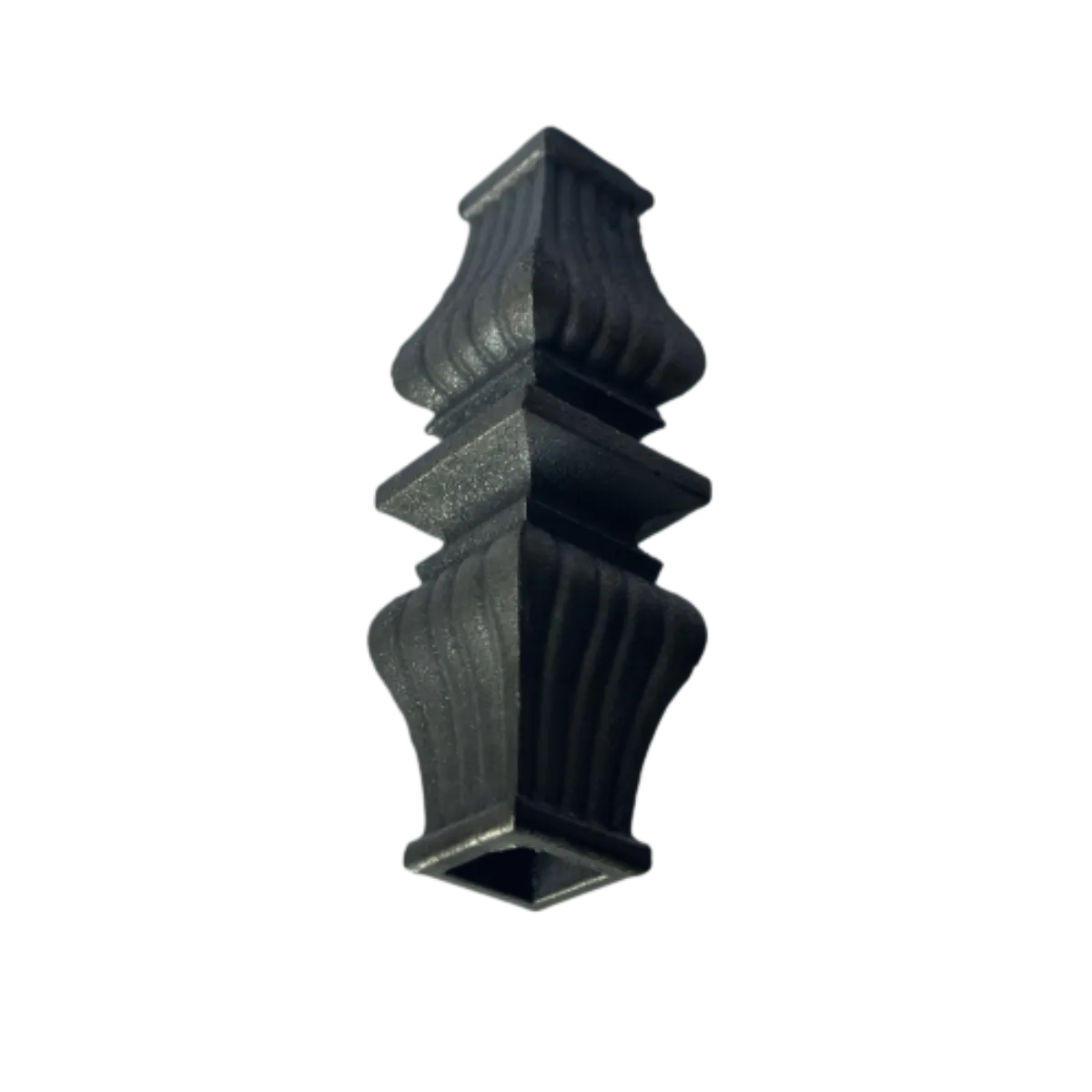

Most of these features, which used to be unique to iron, are now available in steel, which is by a large margin the superior material. And visually, the only difference between the two is the texture. Steel is smooth, while iron has a visible grain, whether it is produced by casting, or by pulling. This grain is actually caused by impurities in the iron and is what accounts for its unreliable nature. These impurities cause weak points in the iron that can lead to breakage when it’s put under stress. Steel’s smooth appearance results from the fact that these impurities have been burned out, or, in the case of carbon, evenly distributed throughout the material. When you think of the medieval blacksmith hammering away, what he is doing is distributing the carbon evenly to turn iron into steel.

While at it, you should be careful not to overheat it to a melting point, often about 1200° F. An ideal heating point should be approximately 900° F.

Applications of Aluminium Extrusion Profiles in Windows

This creates a more affordable product that is easier to work with, but still displays similar properties to that of genuine wrought iron.

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly