inserting rock bits techniques and strategies for efficient

...

...

...

...

...

...

...

- The AN2002 series bearings are available in several sizes, with outer diameters ranging from 30mm to 110mm

- 2. Low Friction The rolling motion of the rollers reduces friction between the bearing components, resulting in lower heat generation and longer bearing life.

- Moreover, in the manufacturing and industrial machinery sectors, the 6022 ZZ bearing is crucial for the efficient functioning of conveyor systems, pumps, and even wind turbines

- In conclusion, the contact angle of a bearing is an essential parameter that influences its performance and lifespan. By understanding its effects on load capacity, friction, wear resistance, rotational accuracy, moment capacity, and internal clearance, engineers can select the appropriate bearing for their specific application. Proper selection and installation of bearings with the correct contact angle can ensure reliable operation and extend the service life of mechanical systems.

- In real-world applications, however, thrust loads can vary and may exceed the rated load capacity of the bearings

ball bearing thrust load. To address this, various techniques can be employed to mitigate the effects of thrust loads on ball bearings. One common approach is to use multiple bearings arranged in a tandem or back-to-back configuration, which distributes the load among the bearings and reduces the overall thrust load on each bearing. - Conclusion

- Bearings are essential components in various machinery systems, providing smooth rotation and support to rotating parts. Among these, 4203/202RS bearings are particularly noteworthy due to their unique design and performance characteristics. This article aims to explore the evolution and significance of 4203/202RS bearings, highlighting their applications, advantages, and future prospects.

- Design:

- At the heart of the 6209 bearing's design lies its ability to manage both high-speed rotation and heavy radial loads. This is achieved through the use of high-carbon chrome steel, which provides excellent strength and wear resistance. The bearing's inner and outer rings are precisely machined to accommodate the balls, which roll smoothly between them, reducing friction and energy loss.

- High precision deep groove ball bearings are essential components in many mechanical systems, providing smooth rotation and reduced friction. These bearings are designed to withstand high speeds and heavy loads, making them ideal for use in a wide range of industrial applications.

- 62211 bearing dimensions refer to the specific measurements of a type of bearing that is commonly used in various machinery and equipment. A bearing is a crucial component in most mechanical systems as it helps reduce friction between moving parts, thus enabling smooth and efficient operation.

- One of the key factors that make deep groove ball bearings stand out is their contact angle. The contact angle refers to the angle between the line connecting the contact points of the ball and the raceway and the horizontal plane. In deep groove ball bearings, the contact angle is typically between 15° and 25°. This unique design allows the bearings to accommodate both radial and axial loads simultaneously, making them highly versatile.

- In conclusion, the price of a 22226 bearing is a critical factor for buyers to consider when making purchasing decisions. By carefully evaluating the cost, quality, and availability of the bearing, buyers can make an informed decision that meets their needs and budget constraints. Ultimately, investing in a high-quality and reliable 22226 bearing can pay off in the long run by ensuring optimal performance and durability for various industrial applications.

- Maintenance of Bearing 51309

- In conclusion, tapered roller bearings are a vital component in many types of machinery, providing reliable support and reducing friction to enhance performance. Their ability to handle heavy loads, withstand misalignment, and operate at high speeds and temperatures make them an ideal choice for a wide range of applications. With proper maintenance, these bearings can provide long-lasting performance and reduce downtime in industrial settings.

- The tolerance class and material composition also play a significant role in determining the bearing's performance

- 2. Load Capacity With a high load capacity, the 6205 bearing can withstand heavy loads and shock loads commonly encountered in industrial machinery and equipment. Its robust design ensures reliable performance even under harsh operating conditions.

- Overall, SKF deep groove ball bearings are a reliable and versatile solution for a wide range of industrial applications. With their high performance, durability, and ease of maintenance, these bearings play a crucial role in ensuring the smooth operation of machinery and equipment in various industries. Choose SKF deep groove ball bearings for your next project and experience the difference in performance and reliability.

- Deep Groove Ball Bearings, on the other hand, are a subclass of ball bearings with a deeper groove in the raceways of both the inner and outer rings. This design enhancement allows them to not only support radial loads but also accommodate axial loads in both directions, making them more versatile than standard ball bearings. Their increased load-bearing capacity makes them suitable for applications involving heavier loads, such as automotive engines, pumps, and conveyors.

- After installing the bearing, rotate the shaft to test the bearing's performance. Ensure that the bearing rotates smoothly and quietly with no signs of vibration or binding.

- * Long service life The 23268 bearing is made from high-quality materials and subjected to strict quality control during manufacturing, resulting in a long service life.

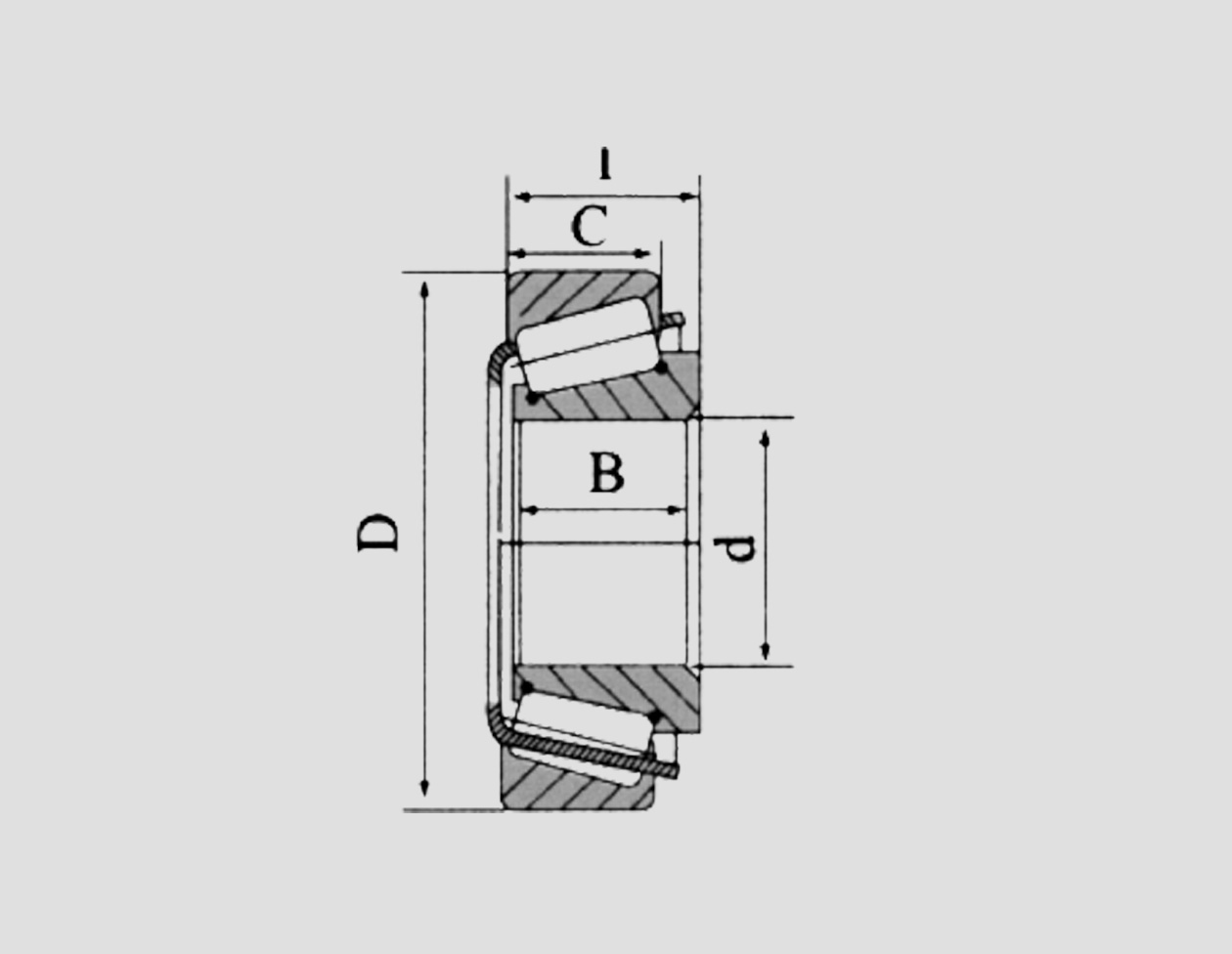

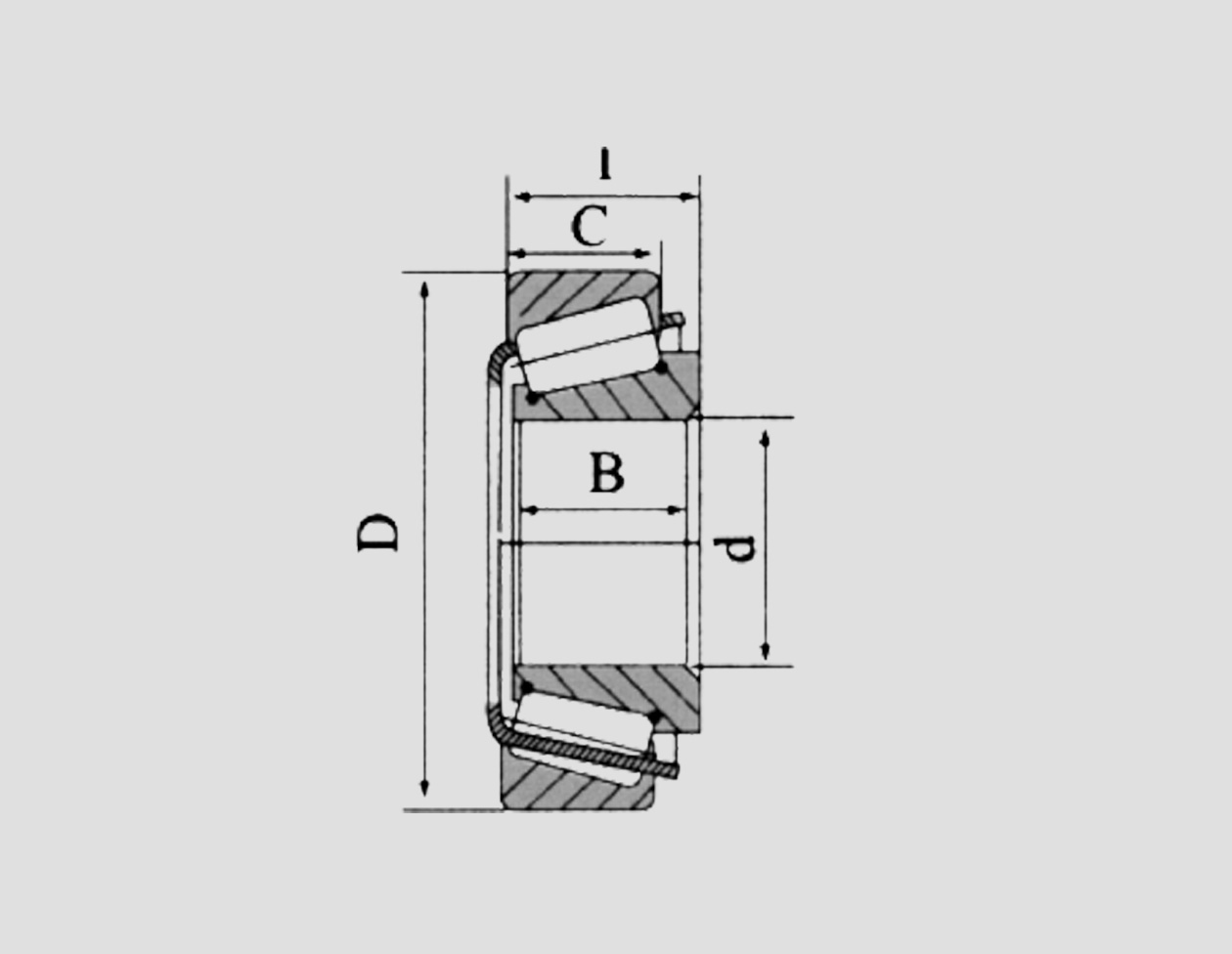

- Tapered roller bearings are designed to handle both radial and axial loads by supporting the forces in one direction. They have tapered inner and outer ring raceways, which allows the rollers to make contact at a point, providing high radial and axial load capacity

four types of roller bearings. Tapered roller bearings are commonly used in gearboxes, axles, and wheel hubs. - In addition to aiding in the selection process, the taper bearing ID and OD chart can also be a valuable resource for troubleshooting and maintenance

taper bearing id od chart. By referencing the chart, technicians can quickly identify the correct replacement bearing for a faulty or worn-out component. This can help minimize downtime and keep the system running smoothly. - Furthermore, the taper bearing ID and OD chart can be an invaluable tool for inventory management. By keeping track of the various bearing sizes and dimensions in a centralized chart, organizations can ensure that they have the right bearings on hand when needed. This can help streamline maintenance processes and reduce unnecessary downtime.

- The use of the 23268 bearing offers numerous benefits, including

- The primary advantage of a tapered roller bearing lies in its ability to manage both thrust and radial loads simultaneously. The tapered design enables the distribution of stress evenly across the rolling elements, minimizing wear and enhancing durability. These bearings are particularly suitable for applications where high radial loads and moderate thrust loads are present, such as in automotive wheel hubs, gearboxes, and heavy machinery.

- * Aerospace Aircraft engines and helicopters

Some potential disadvantages of spherical roller bearings include:

- 2. Automotive industry Conical roller bearings are used in various automotive components, such as transmission systems, differentials, and wheel hubs. Their ability to handle both radial and axial loads ensures reliable performance in demanding environments.

- * C is the radial clearance

- 4. Enhanced Safety The robust construction and corrosion resistance of the bearing make it suitable for use in harsh environments, enhancing the safety of personnel and equipment.

- In the automotive industry, these bearings are commonly found in transmission systems, helping to manage the immense pressure exerted during gear shifts

- In the world of mechanical engineering, bearings are fundamental components that enable rotational movement and support structural loads. The term 6907 bearing dimensions refers to the specific measurements associated with a type of deep groove ball bearing, designated by the code 6907. This model is widely used due to its versatility and reliability in various applications. To understand the importance of these dimensions, one must delve into the technical specifications and their impact on performance.

- Manufacturers often use high-quality materials like carbon steel or stainless steel for the construction of these bearings, providing resistance against corrosion and wear. Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments mounted spherical roller bearings. The precision machining and heat treatment processes used in their production guarantee consistent performance and durability.

mounted spherical roller bearings. The precision machining and heat treatment processes used in their production guarantee consistent performance and durability. - In conclusion, 6209 zz is not just a random string but a microcosm of the complex interplay between human ingenuity and machine language. It's a reminder that behind every digital facade lies a world of intricate algorithms, hidden meanings, and endless possibilities, waiting to be explored and unraveled.

- The 20% deep groove ball bearing is widely used in a variety of applications due to its versatility and performance. Some of the most common applications include

- In conclusion, the 6211 2rs bearing is a versatile and reliable component that plays a crucial role in the smooth operation of various types of machinery and equipment. Its high-quality construction and protective seals make it a popular choice for industrial applications where precision and efficiency are essential. Whether in agricultural machinery, automotive equipment, or other industrial settings, the 6211 2rs bearing is a dependable solution for ensuring optimal performance and longevity.

- In industrial applications, thin tapered roller bearings find extensive use in automotive, aerospace, mining, and heavy machinery industries

- This bearing finds extensive use in a wide range of industries, from automotive to aerospace, from industrial machinery to consumer electronics

- Overall, the taper bearing ID and OD chart is an essential reference tool for anyone working with taper bearings. Whether selecting a bearing for a new application or troubleshooting an existing system, this chart provides the necessary information to make informed decisions. By leveraging the information in the chart, users can ensure the reliable performance and longevity of their mechanical systems.

- One of the key benefits of the 6202 rz bearing is its ability to withstand high speeds and heavy loads without compromising performance. This is due to the high-quality materials and precision engineering that goes into the production of these bearings, ensuring durability and longevity under even the most demanding conditions.

- * Maximum load capacity The maximum axial load that the bearing can withstand.

- 5. Assembling The rollers, cage, and inner and outer rings are assembled in a specific sequence to form the complete bearing.

- Another benefit of the 28985 bearing is its ease of installation and maintenance. With proper care and lubrication, this type of bearing can operate smoothly for extended periods, reducing the need for frequent replacements. This not only saves time and money but also helps prevent unexpected breakdowns that can disrupt operations.

- In the automotive industry, the 6022 ZZ bearing is often found in engine components, such as alternators and water pumps, ensuring smooth and reliable rotation. In the aerospace sector, where precision and reliability are paramount, these bearings are utilized in various aircraft mechanisms, contributing to flight safety and performance.

- The Unparalleled Performance of 32236 Bearing A Comprehensive Guide

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments

Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments Additionally, some bearings may incorporate seals or shields to protect against contaminants, extending their service life even in harsh environments mounted spherical roller bearings. The precision machining and heat treatment processes used in their production guarantee consistent performance and durability.

mounted spherical roller bearings. The precision machining and heat treatment processes used in their production guarantee consistent performance and durability.