fiberglass 90 degree elbow

...

2025-08-15 09:31

1721

The Versatile Role of Fiberglass Agitating Tanks in Industrial Processes

...

2025-08-15 08:56

1184

In addition to their strength and durability, FRP tanks are also highly customizable fiberglass reinforced plastic tank. They can be designed and manufactured to meet specific requirements, whether it's the size, shape, or configuration of the tank. This makes them an ideal solution for a wide range of applications, from small residential storage tanks to large industrial storage facilities.

fiberglass reinforced plastic tank. They can be designed and manufactured to meet specific requirements, whether it's the size, shape, or configuration of the tank. This makes them an ideal solution for a wide range of applications, from small residential storage tanks to large industrial storage facilities.

...

2025-08-15 08:55

791

The safety aspect of FRP playground equipment is further enhanced by its slip-resistant properties, especially important for wet surfaces or rainy days. Additionally, the material can be easily molded into various textures, adding an extra layer of sensory stimulation for children.

...

2025-08-15 08:45

2325

Twist drills, with their helical cutting edges, became the standard for 75mm drill bits in the 1960s. These drills cut by shearing the material and ejecting it through the flutes, resulting in cleaner holes with less material buildup. The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels

The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels The development of twist drills also led to the refinement of drill bit geometry, including the addition of secondary cutting edges and better chip evacuation channels 75mm drill bit.

75mm drill bit.

...

2025-08-15 08:21

120

FRP, or Fiber Reinforced Polymer, has emerged as a revolutionary material in the construction and engineering industry, particularly in the manufacturing of spraying pipes. This cutting-edge technology offers a myriad of benefits that conventional materials often fail to provide. This 600-word article delves into the intricacies of FRP spraying pipes, their advantages, applications, and their pivotal role in shaping the future of infrastructure.

...

2025-08-15 08:17

423

The T38 Drill Rod A Revolution in Drilling Technology

...

2025-08-15 07:36

944

Tap Drill Bits A Comprehensive Guide

...

2025-08-15 07:21

2267

Some key maintenance tasks include

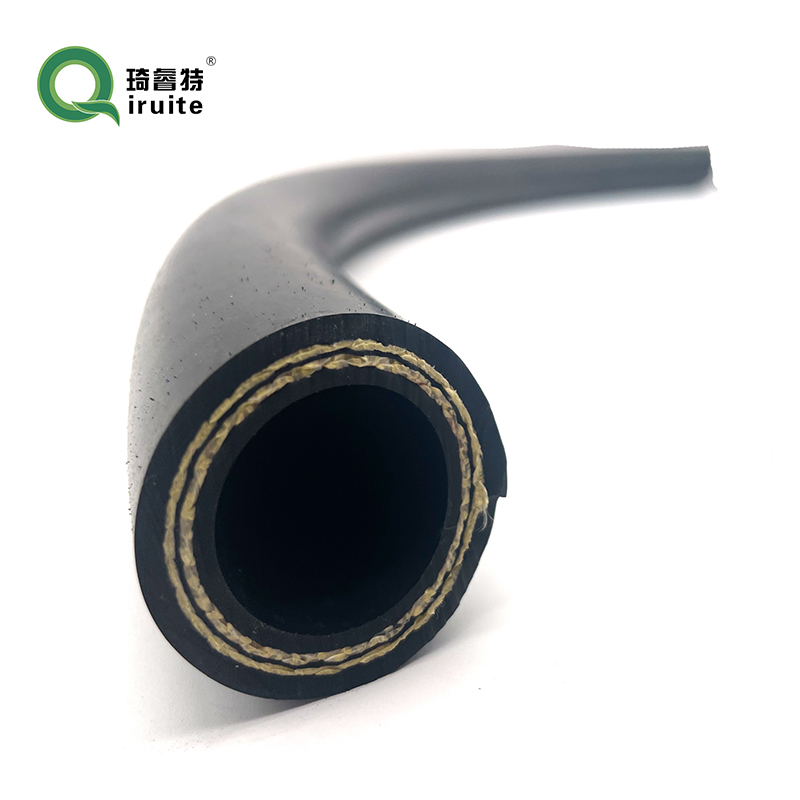

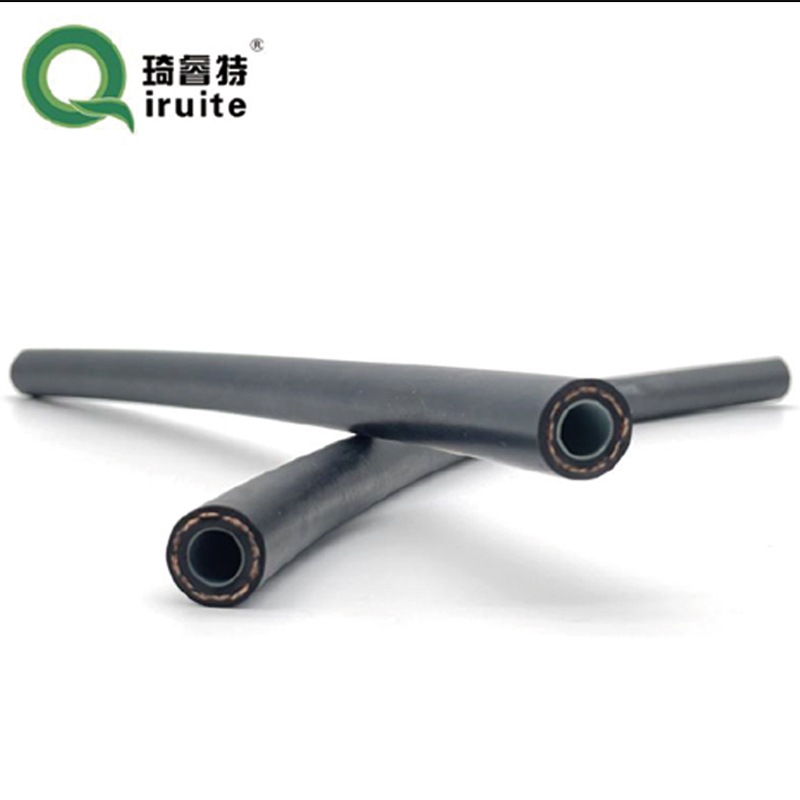

Some key maintenance tasks include Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

Over-tightening can cause thread damage, while under-tightening may compromise the seal Over-tightening can cause thread damage, while under-tightening may compromise the seal

If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment

If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment If a replacement is needed, they will disconnect the faulty hose, safely dispose of it, and then install a new one, ensuring proper sealing and alignment