For instance, in construction sites, yellow tape may be used to outline areas that are off-limits or require special attention. In warehouses, it can signify pathways or areas where heavy machinery operates. By using yellow insulation tape, organizations can ensure that workers are aware of potential hazards, thereby reducing accidents and enhancing overall safety.

If you love tapes like we do, then you know how important electrical tape is. Today, I want to talk about 3M Rubber Electrical Tapes. As experts in all kinds of tapes we are excited to share our knowledge and enthusiasm for these amazing tapes and the applications they can be used in.

In plumbing, it swiftly mends leaks, providing a temporary or permanent fix without the need for specialized tools or messy adhesives In plumbing, it swiftly mends leaks, providing a temporary or permanent fix without the need for specialized tools or messy adhesives

In plumbing, it swiftly mends leaks, providing a temporary or permanent fix without the need for specialized tools or messy adhesives In plumbing, it swiftly mends leaks, providing a temporary or permanent fix without the need for specialized tools or messy adhesives self amalgamating tape waterproof.

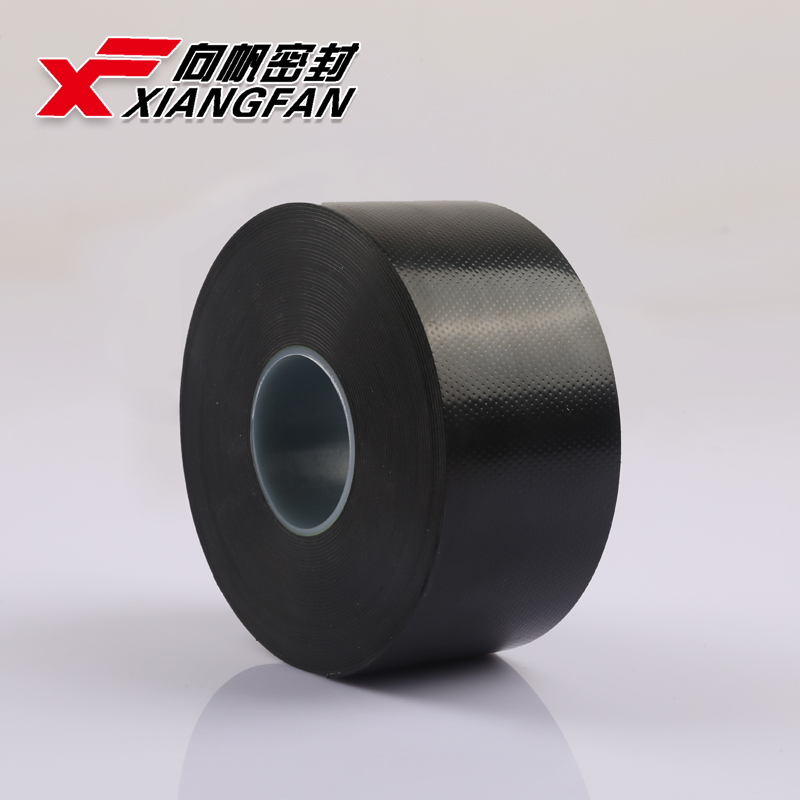

self amalgamating tape waterproof.Control Type

We’ll also provide some tips on how to choose the right type of tape for your needs!

Installation of fire-resistant drywall tape is much like standard tape, but it does require attention to detail to ensure optimal performance. It is often applied in tandem with a fire-resistant joint compound, which further enhances the fire-resistant properties of the completed wall. Proper installation techniques, including ensuring the tape is adequately bedded in the compound, are vital for achieving a seamless finish that also adheres well to fire safety standards.

What is a control box?

Since it’s an affable tape, it’s popular amongst electricians. It adheres easily and can get manipulated to fit in tight spaces and around oddly shaped materials. Mastic tape is a highly revered choice for outdoor wiring needs, as it has excellent moisture and UV resistant capabilities.

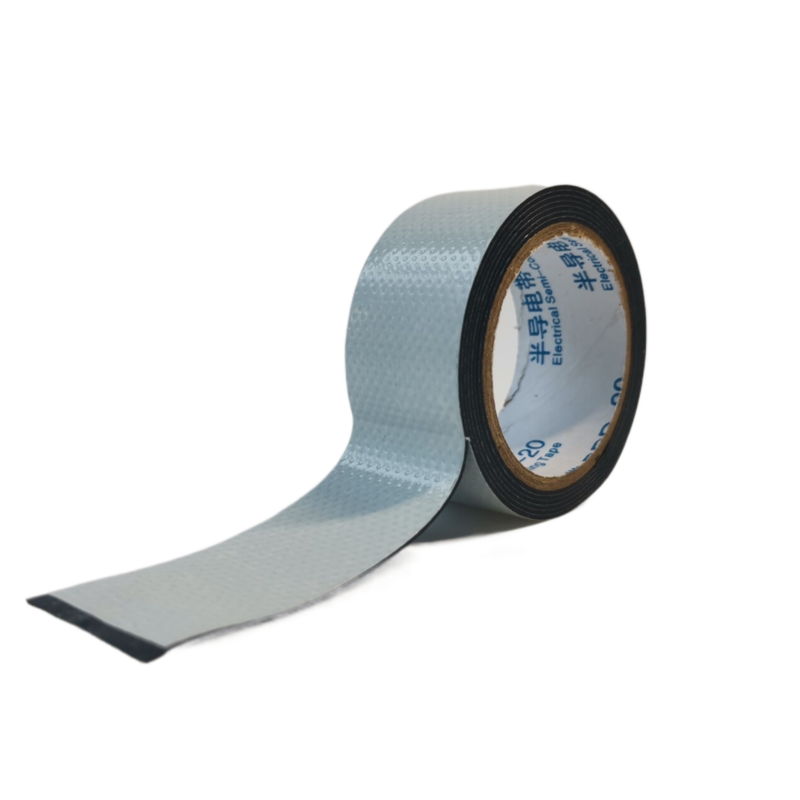

2. Durability Made to withstand extreme temperatures and harsh environments, self-fusing rubber tape maintains its effectiveness and integrity over time. Its resistance to abrasion, UV radiation, and chemical exposure ensures longevity, even in challenging conditions.

As mentioned, different colors indicate different types of electrical tape features. Many standard electrical tapes are sold in black, but you can find them in nearly every color. Choose the color of tape based on the application you will be using it for and its voltage, phase, and other electric-relevant information.

clear waterproof flex tape. It does not require complicated tools or techniques; a simple hand stretch activates its adhesive properties. Furthermore, it can be easily cut and shaped to fit any size of repair, making it a versatile option for various tasks.

clear waterproof flex tape. It does not require complicated tools or techniques; a simple hand stretch activates its adhesive properties. Furthermore, it can be easily cut and shaped to fit any size of repair, making it a versatile option for various tasks.

self fusing rubber tape. Once applied, it can withstand years of wear and tear without losing its adhesive properties. This makes it a cost-effective solution for long-lasting repairs and installations.

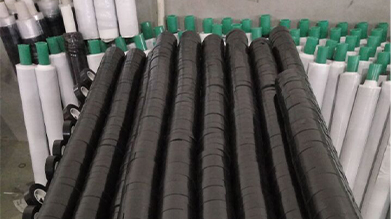

It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure

It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure It is widely used in manufacturing plants, chemical facilities, and oil refineries to seal and protect vital infrastructure fireproof adhesive tape. In construction, it is applied to building materials to increase fire resistance and comply with stringent safety regulations.

fireproof adhesive tape. In construction, it is applied to building materials to increase fire resistance and comply with stringent safety regulations.

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution.

3M also makes an electrical tape made of silicone rubber for applications where Class “H” (180°C/356°F) temperatures are encountered i.e., silicone rubber cables.

5. Easy Application Applying self-fusing rubber tape is straightforward. It can be easily wrapped around wires or surfaces without requiring special tools or adhesives. Once layered, the tape fuses to itself, providing a snug fit that ensures effective insulation and protection.

Its peel-and-stick application eliminates the need for messy liquids or complicated tools Its peel-and-stick application eliminates the need for messy liquids or complicated tools

Its peel-and-stick application eliminates the need for messy liquids or complicated tools Its peel-and-stick application eliminates the need for messy liquids or complicated tools gray flex seal tape. Simply cut to size, remove the backing, and press firmly onto the surface. The tape adheres instantly, creating a strong bond that resists peeling, tearing, or cracking.

gray flex seal tape. Simply cut to size, remove the backing, and press firmly onto the surface. The tape adheres instantly, creating a strong bond that resists peeling, tearing, or cracking.