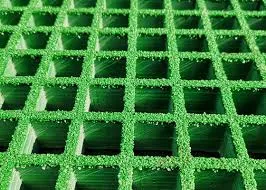

In addition to their customizable design, GRP handrails are also easy to install and maintain. Unlike traditional metal or wood handrails, which can require regular painting or sealing to prevent corrosion or rot, GRP handrails are resistant to weathering and require minimal upkeep. This makes them a cost-effective and low-maintenance option for property owners looking to enhance the safety and appearance of their space

In DIY projects, a 1 inch drill bit is a staple

Conditional Access Enforcement is the final element of CNAP 711

- Regularly inspect for signs of wear, damage, or leaks.

Benefits of Using Rubber Air Hoses

- Avoid Overextension Do not stretch the hose beyond its capacity. This can lead to tears and weakening of the material.

2. Agricultural Machinery Tractors and other farm equipment rely on these hoses to perform tasks such as plowing, planting, and harvesting efficiently. The robustness of the 5 8 hose ensures that it can withstand abrasive materials and fluctuating pressure levels typical in agricultural environments.

Applications of Braided Hose

Understanding Brake Hose Replacement Costs

1. High Pressure Resistance One of the standout characteristics of wire braided hoses is their ability to withstand high-pressure applications. The braided wire construction provides added strength, making them suitable for applications where pressure fluctuations are frequent.

Estimated Costs

To ensure the longevity and reliable performance of hydraulic hoses rated at 3000 PSI, regular maintenance is essential. Here are some best practices

- Construction In heavy machinery like excavators and bulldozers, hydraulic hoses are essential for the operation of various functions, such as lifting and pushing.

Applications Across Industries

The transportation industry also benefits from hydraulic rubber hoses, particularly in vehicles such as trucks and buses that depend on hydraulic braking systems and steering mechanisms. The integrity of these hoses is critical to safety, as any failure could lead to catastrophic results.

- Power Generation Power plants that generate electricity often use steam turbines. High pressure steam hose pipes are used to transport steam from boilers to turbines, making them critical to the energy production process.

- Construction In heavy machinery like excavators and bulldozers, hydraulic hoses are essential for the operation of various functions, such as lifting and pushing.

Conclusion

Introduction

Furthermore, the durability of hydraulic hoses is another critical aspect that cannot be overlooked. Industrial operations often involve harsh environments, exposure to chemicals, extreme temperatures, and heavy mechanical stress. Quality hydraulic hoses are designed to withstand these challenging conditions, ensuring that they can endure the rigors of daily use without deteriorating prematurely. This durability not only contributes to the longevity of the hoses but also minimizes the need for frequent replacements, ultimately reducing maintenance costs for industrial businesses.

Key Features of Rubber Airline Hoses

En la agricultura, el uso de mangueras hidráulicas también es crucial, especialmente en equipos como tractores y sembradoras, donde se requiere un suministro constante y confiable de fluidos para la operación de los sistemas hidráulicos. De esta manera, se optimizan las tareas agrícolas, aumentando la eficiencia y reduciendo el tiempo de trabajo en el campo.

3 hydraulic hose

Applications of 1% 4% Compressor Hoses

- Cost Savings Although the initial investment in spiral wire hoses might be higher than standard hoses, their longevity and reduced need for maintenance can lead to significant cost savings over time.

High pressure steam hose pipes find use in a multitude of sectors

Conclusion

ポリエアホースのりいについては、にしっかりときることでをばすことができます。また、のチェックやなをうことで、れやをにぐことができます。

Care and Maintenance of Steam Cleaner Hoses

Secondly, hand crimpers are cost-effective. Unlike larger hydraulic machines, which can be prohibitively expensive, hand crimpers are relatively affordable. This accessibility enables smaller businesses and independent technicians to invest in quality tools without significant financial strain. Moreover, the ability to perform in-house assembly and repairs reduces reliance on external services, further saving costs in the long run.

Recognizing the signs of a deteriorating brake hose is essential for vehicle safety. Common indicators include

The Importance of Hydraulic Hose Hand Crimpers in Various Industries

1. Inspection Regularly check hoses for signs of wear, abrasions, or leaks. Any visible damage should be addressed immediately to prevent failures.

Conclusion

3. Shop Around Don’t hesitate to obtain quotes from different repair shops. Some may offer promotions or discounts that can significantly reduce the replacement costs.

What is a Spiral Wire Hose?

Functionality of Hydraulic Hose Hand Crimpers

Hydraulic oil hoses are vital components in hydraulic systems, ensuring the system's efficiency, reliability, and safety. Understanding their importance, types, features, and applications can help industries choose the right hoses for their specific needs. Regular maintenance and timely replacement of worn-out hoses can prevent breakdowns and improve the overall performance of hydraulic machinery. Investing in high-quality hydraulic oil hoses is not just a choice; it is a necessity for ensuring operational excellence across various sectors.

5. Oil and Weather Resistant The synthetic rubber layers protect against oil degradation and weather impacts, ensuring a longer service life.

- Automotive Applications Some automotive hydraulic systems, including brakes and steering, can benefit from the robustness of SAE 100R2AT hoses.

What is a Silicone Intake Hose?

Understanding Brake Hose Replacement Costs

Портативдүү аба компрессорунун шлангын сатып алууда, анын узундугу, диаметри, материалы жана температуралык диапазону сыяктуу факторлорду эске алуу зарыл. Ар бир проекттин өзгөчөлүктөрүнө жараша тандоо керек.

Applications Beyond Power Steering

High-pressure hoses with 1% and 4% ratings have diverse applications across various industries

Advantages of Using Hydraulic Hose Hand Crimpers

The primary function of a fuel hose is to deliver the fuel from the fuel tank to the engine. This pathway must be reliable, as any leaks or ruptures can lead to not only performance issues but also severe safety hazards, including the risk of fire. Consequently, the selection of the right fuel hose is pivotal, and it should comply with industry standards and regulations.

- Regular Inspection Check the hose for any signs of wear, such as cracks or leaks. Early detection can prevent more significant issues in the future.