These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery

These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery These covers serve as a barrier against environmental factors such as dust, moisture, and corrosive chemicals, ensuring the longevity of the machinery fiberglass cover. Additionally, they provide an extra layer of safety by preventing accidental contact with moving parts or hot surfaces.

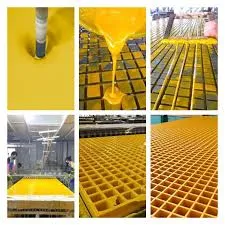

fiberglass cover. Additionally, they provide an extra layer of safety by preventing accidental contact with moving parts or hot surfaces.FRP grating is widely used in various sectors and industries around the world. FRP Grating is more resilient and impact than aluminum or steel grating. The advantages of FRP Grating include light weight, corrosion resistance, UV resistance, anti-slip, easy to install, and requires little maintenance. FRP Grating can also be designed in various sizes, shapes, and configurations to suit specific application needs. In short it’s no wonder you find ones often used for sidewalks, platforms, catwalks, stair treads, trench covers and more. HI-Grid FRP Molded Grating is designed to withstand this wide range of applications. But of the many buildings, what is the most popular application for HI-Grid FRP Grating systems? Let’s see the list below!

Because they allow miners to access deeper deposits, they reduce the need for surface mining, which can cause significant damage to the environment Because they allow miners to access deeper deposits, they reduce the need for surface mining, which can cause significant damage to the environment

Because they allow miners to access deeper deposits, they reduce the need for surface mining, which can cause significant damage to the environment Because they allow miners to access deeper deposits, they reduce the need for surface mining, which can cause significant damage to the environment

The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation

The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation The thread design on some shanks enables a screw-in connection, ensuring a tight fit and preventing slippage during operation