Hengshui Jrain Frp fiberglass vessels and tanks

The Art of Drilling Through Rock A Journey into the Earth's Crust

In addition to their durability and versatility, impact driver drill bits also provide better control and accuracy when driving fasteners

impact driver drill bits. The quick rotational motion of impact drivers allows you to start and stop driving screws with precision, making it easier to achieve a flush finish without overdriving or stripping the fastener.

In conclusion, button bit manufacturers are an integral part of the construction and mining machinery ecosystem. Their work is critical in ensuring the efficiency, safety, and success of drilling operations worldwide. As technology advances and sustainability becomes a priority, these manufacturers continue to innovate, shaping the future of drilling technology.

FRP grating is incredibly strong and durable due to its construction from glass fibers embedded within a resin matrix. Its superior strength makes it ideal for heavy-duty applications such as factory floors, stairs, walkways, platforms, and more. Additionally, it is corrosion resistant to harsh chemicals and weather conditions which makes it perfect for both indoor and outdoor use. The grates are available in different sizes and configurations, so you can choose the right one for your specific needs.

FRP demisters contribute significantly to sustainability efforts as well. In wastewater treatment facilities, they help in removing oil and other contaminants from water before it is discharged or recycled. This practice conserves water resources and prevents ecological damage caused by polluted water systems.

Key Features of FRP Scrubber

In addition to these, the material is finding increasing application in the manufacturing of sporting goods like surfboards, tennis rackets, and protective gear due to its impact resistance and flexibility. It's also used in the creation of sculptures, tanks, and even furniture, demonstrating its aesthetic appeal and adaptability.

...

2025-08-14 15:16

1812

Despite their durability, it's crucial to understand that the efficiency of carbide drill bits depends on using the right bit for the job, maintaining the correct speed and feed rate, and ensuring proper cooling to prevent thermal damage. Operators must also be mindful of the drilling technique to avoid breaking the bits, especially when working with unpredictable materials.

Boat hulls, decks, and other structural elements are often fabricated from this material due to its water-resistant nature and ability to withstand harsh marine environments Boat hulls, decks, and other structural elements are often fabricated from this material due to its water-resistant nature and ability to withstand harsh marine environments

Boat hulls, decks, and other structural elements are often fabricated from this material due to its water-resistant nature and ability to withstand harsh marine environments Boat hulls, decks, and other structural elements are often fabricated from this material due to its water-resistant nature and ability to withstand harsh marine environments fiberglass cover. Fiberglass boats are known for their longevity, low maintenance requirements, and resistance to osmosis.

fiberglass cover. Fiberglass boats are known for their longevity, low maintenance requirements, and resistance to osmosis.

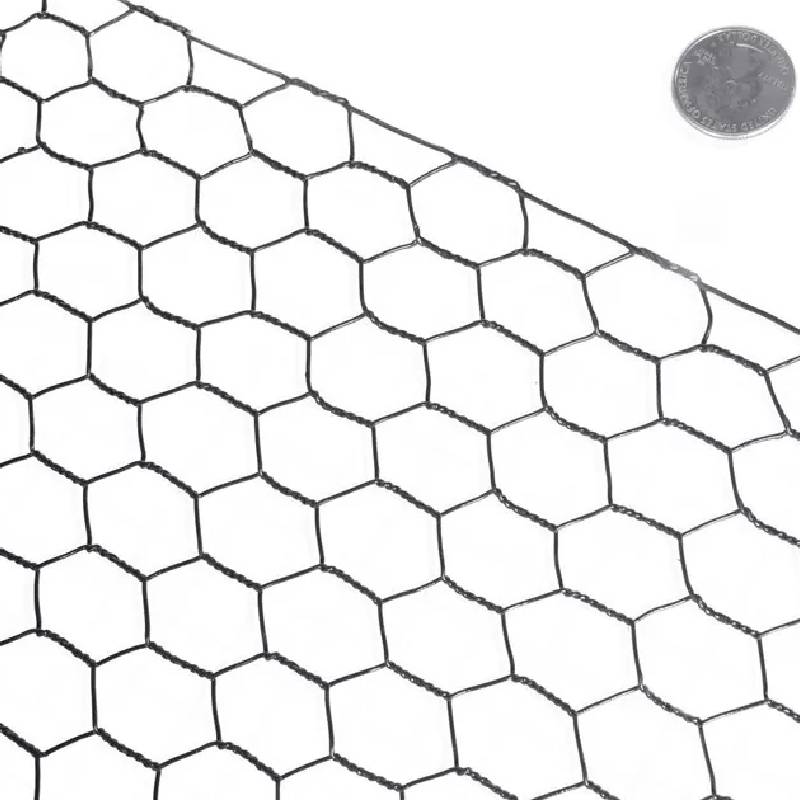

The cage features a unique, open design that allows air and sunlight to reach the tomato plants, promoting healthy growth and reducing the risk of disease The cage features a unique, open design that allows air and sunlight to reach the tomato plants, promoting healthy growth and reducing the risk of disease

The cage features a unique, open design that allows air and sunlight to reach the tomato plants, promoting healthy growth and reducing the risk of disease The cage features a unique, open design that allows air and sunlight to reach the tomato plants, promoting healthy growth and reducing the risk of disease It is used to make fences, gates, and other enclosures to keep animals in or out of certain areas It is used to make fences, gates, and other enclosures to keep animals in or out of certain areas

It is used to make fences, gates, and other enclosures to keep animals in or out of certain areas It is used to make fences, gates, and other enclosures to keep animals in or out of certain areas

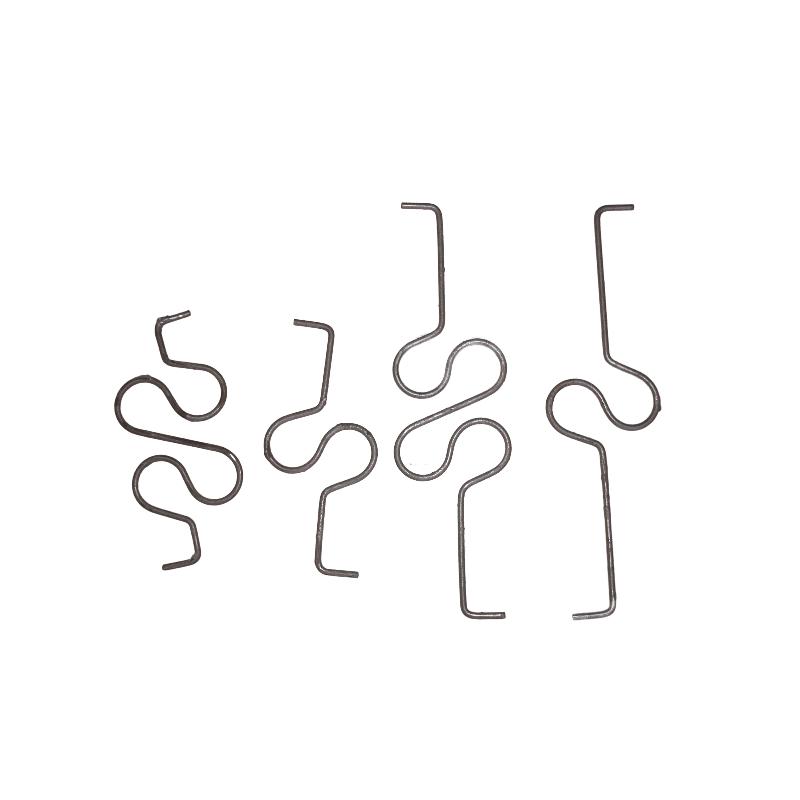

Drill holes at a depth that is equal to the length of the tie plus 1 inch (2 Drill holes at a depth that is equal to the length of the tie plus 1 inch (2

Drill holes at a depth that is equal to the length of the tie plus 1 inch (2 Drill holes at a depth that is equal to the length of the tie plus 1 inch (2