Hengshui Jrain Frp fiberglass for steel smelting plant.

...

...

...

...

...

...

...

...

...

...

- The double seal feature also enhances the bearing's resistance to friction. With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating 6312 zz bearing. In applications such as electric motors, power tools, or gearboxes, the 6312 zz bearing proves to be an excellent choice for sustained performance.

6312 zz bearing. In applications such as electric motors, power tools, or gearboxes, the 6312 zz bearing proves to be an excellent choice for sustained performance. - Understanding the different types of cylindrical roller bearings is crucial for engineers and maintenance professionals to ensure that the correct bearing is selected for each specific application. Proper selection leads to increased efficiency, extended operational life, and reduced maintenance costs. As technology advances, the development of new materials and designs continues to expand the capabilities of cylindrical roller bearings, ensuring they remain a cornerstone in mechanical systems for years to come.

- The double seal feature also enhances the bearing's resistance to friction. With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating 6312 zz bearing. In applications such as electric motors, power tools, or gearboxes, the 6312 zz bearing proves to be an excellent choice for sustained performance.

6312 zz bearing. In applications such as electric motors, power tools, or gearboxes, the 6312 zz bearing proves to be an excellent choice for sustained performance. - In conclusion, the 62305 bearing, with its specific dimensions of 25mm ID, 62mm OD, and 17mm width, offers a reliable solution for various applications. Its design, combined with the right tolerances and materials, makes it a versatile and dependable choice in the realm of bearings. Always consult manufacturer specifications and consider operating conditions when choosing the perfect 62305 bearing for your project.

- The design of these bearings includes a deep groove, which allows for increased ball capacity. This enhances the load-carrying capability and provides better contact stress distribution within the bearing. The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial high temperature deep groove ball bearing.

high temperature deep groove ball bearing. - The LM501349 bearing is a part of the linear ball bearing series, designed to provide exceptional support and motion control in linear motion systems. Its unique dimensions, with a width of 49mm and a specific design, cater to the needs of industries where precise movement and reduced friction are paramount. From robotics to aerospace, this bearing finds its application across a broad spectrum.

- In addition to steel and ceramic, other materials such as bronze and titanium can also be used for deep groove ball bearings. Bronze offers excellent anti-corrosion properties and is often used in marine environments or applications involving lubricants with high acidity levels. Titanium is lightweight yet incredibly strong and durable, making it suitable for aerospace and military applications where weight reduction is crucial.

- Use a mounting tool or press to evenly seat the bearing onto the shaft. Apply pressure gradually and evenly to avoid damaging the bearing

taper roller bearing installation procedure. Check the bearing to ensure it is seated properly and securely. - For instance, in heavy-duty automotive or industrial machinery, larger bearing numbers with higher load ratings might be necessary. In contrast, smaller, more compact applications might require bearings with lower numbers but still capable of handling the specific load.

- Overall, the 6005 2RS C3 bearing is a dependable component that offers high performance, reliability, and versatility for a wide range of industrial applications. With its sealed design, C3 clearance, and durable construction, this bearing is an essential part of many machinery and equipment systems, providing smooth rotation and long-lasting operation.

- 1. Design The 6302RS bearing is a deep groove ball bearing with two rows of balls and a contact angle of 15 degrees. This design provides excellent load capacity and stiffness while maintaining a small profile.

- Understanding the Bearing 6204 ZZ A Key Component in Modern Machinery

- 3. Heavy Machinery The bearing is used in construction equipment, mining machinery, and other heavy machinery to support heavy loads and ensure reliable operation.

- The size chart begins with the basic dimensions, which include the diameter of the inner raceway, the outer diameter of the bearing, and its overall thickness. The inner diameter governs the shaft size it can fit onto, while the outer diameter determines the housing or mounting surface it will fit into. The thickness, or width, influences the bearing's load-carrying capacity The thickness, or width, influences the bearing's load-carrying capacity

The thickness, or width, influences the bearing's load-carrying capacity The thickness, or width, influences the bearing's load-carrying capacity

The thickness, or width, influences the bearing's load-carrying capacity The thickness, or width, influences the bearing's load-carrying capacity needle roller thrust bearing size chart.

needle roller thrust bearing size chart. - Maintenance is also a key factor in the popularity of these bearings. With proper lubrication and cleanliness, NUP type cylindrical roller bearings can operate for extended periods without significant degradation. However, regular inspections are necessary to detect any signs of wear or damage that could lead to failure if left unaddressed.

- 2. Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity

Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity

Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity flanged tapered roller bearing.

flanged tapered roller bearing. - Applications of the 51113 Bearing

- In the world of mechanical engineering and industrial machinery, bearings play a pivotal role in ensuring smooth operation and longevity. One such widely used bearing is the 22214 bearing. This specific type of spherical roller bearing is designed to handle high radial loads while also accommodating some degree of axial load. However, when it comes to purchasing these bearings, the price factor is often a significant consideration. Let's delve into the factors that influence the price of a 22214 bearing.

- 3. Precision Tolerance The 638 ZZ bearing boasts tight tolerances, ensuring smooth operation and reducing wear and tear. This precision ensures that the bearing operates within optimal conditions, maximizing its performance and reliability.

- 4

627zz bearing dimensions. Dynamic Load Rating The dynamic load rating of 627ZZ bearings ranges from 1580 to 3090 pounds, depending on the size and quality of the bearing.

627zz bearing dimensions. Dynamic Load Rating The dynamic load rating of 627ZZ bearings ranges from 1580 to 3090 pounds, depending on the size and quality of the bearing. - In the world of engineering and machinery, bearings play an essential role in ensuring smooth and efficient operation. One such bearing that has garnered significant attention is the LM501349 bearing. This remarkable component embodies the perfect blend of precision engineering, durability, and performance, making it a go-to choice for various industrial applications.

- In terms of installation, four-row tapered roller bearings typically require more attention than standard bearings due to their complexity

four row taper roller bearing. They often come pre-lubricated, but it is essential to ensure that lubrication remains adequate throughout the life of the bearing. Proper maintenance includes regular checks for signs of wear, monitoring the lubricant level, and replacing the lubricant as needed.

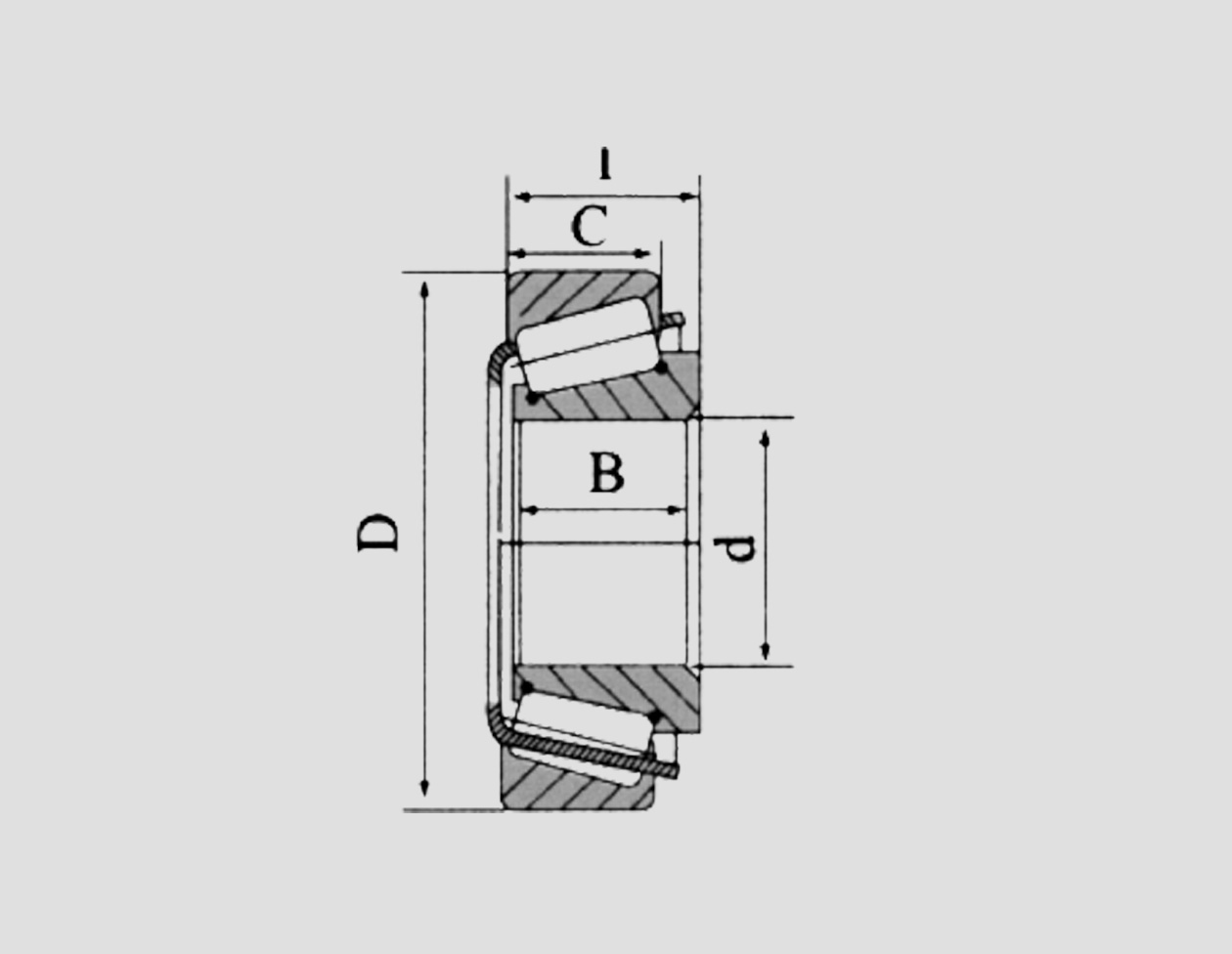

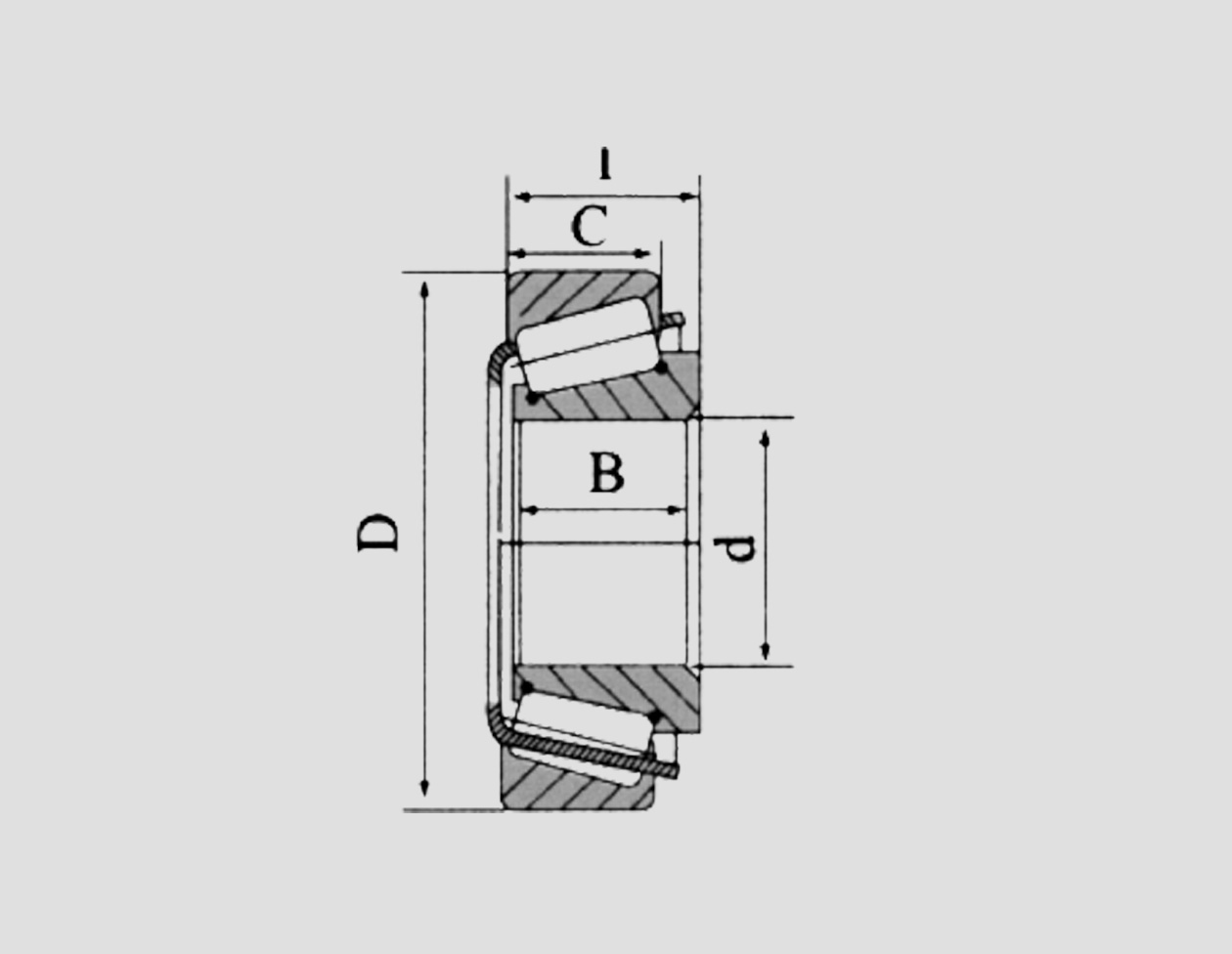

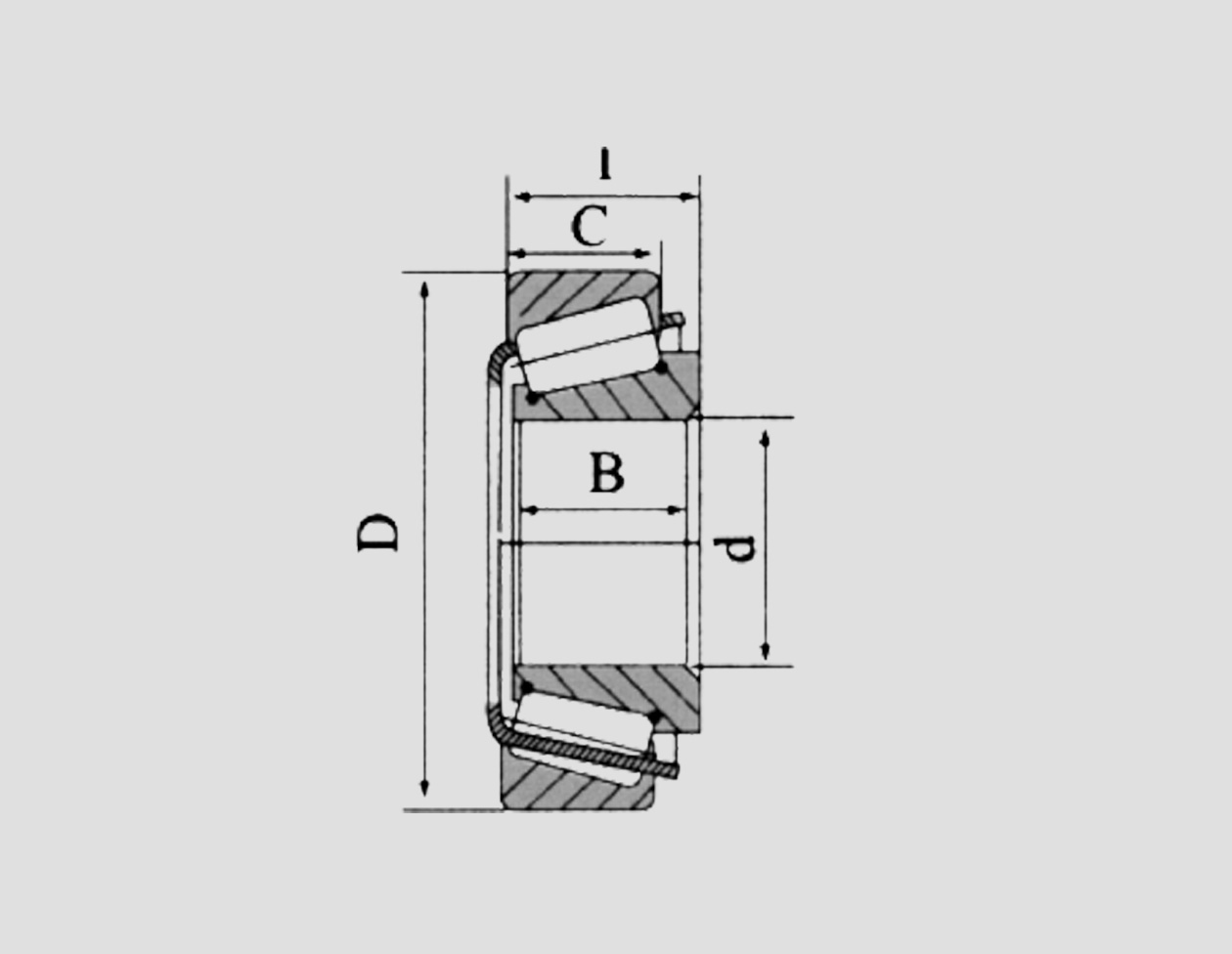

four row taper roller bearing. They often come pre-lubricated, but it is essential to ensure that lubrication remains adequate throughout the life of the bearing. Proper maintenance includes regular checks for signs of wear, monitoring the lubricant level, and replacing the lubricant as needed. - The primary feature of a tapered roller bearing is its conical, which enables it to distribute load evenly across the bearing's surface. The outer ring, inner ring, and roller components all have a common apex, creating a wedge-shaped space that allows for the efficient transfer of forces. This configuration not only enhances load-bearing capacity but also provides excellent stability under heavy loads.

- 1. Precision manufacturing The bearing is manufactured with high-precision tolerances to ensure smooth operation and long service life.

- 5. Full Complement Cylindrical Roller Bearings

- In addition to load capacity and speed rating, the bearing's size also affects its compatibility with other components in the machine

- In conclusion, a thrust needle roller bearing size chart is an indispensable resource for selecting the appropriate bearing for a particular application. By thoroughly understanding and utilizing this chart, engineers can optimize system performance, minimize maintenance needs, and ensure the longevity of their equipment. Always refer to a reliable and up-to-date chart from a reputable manufacturer to make the best choice for your application.

- The 6310 bearing is a reliable and durable solution for a wide range of applications. By understanding its dimensions, material composition, load capacity, and maintenance requirements, users can ensure optimal performance and longevity of the bearing in their specific applications.

- One of the key features of ball thrust bearings is their ability to support axial loads in a specific direction. This makes them ideal for applications where heavy loads need to be transmitted in a straight line, such as in gearboxes, automotive transmissions, and machine tool spindles. By utilizing the rolling action of the balls, ball thrust bearings can handle much higher loads than plain bearings or sleeve bearings.

- Furthermore, the catalogue may also include technical data, dimension drawings, and installation guidelines to assist customers in the proper handling and installation of the bearings. This information helps to ensure that the bearings are properly mounted and aligned, leading to optimal performance and extended bearing life.

- Another renowned supplier is NSK, a Japanese company known for its precision engineering and advanced manufacturing processes. NSK's deep groove ball bearings provide high performance, durability, and energy efficiency, catering to diverse sectors such as automotive, aerospace, and construction.

- Tapered roller bearings, a specialized type of rolling-element bearing, play a pivotal role in various industrial applications due to their ability to handle high radial and axial loads simultaneously. The bearing ID (Inner Diameter) 80mm and OD (Outer Diameter) 140mm specification refers to a particular size that is commonly used in numerous mechanical systems where heavy load-bearing capacity is essential.

- The development of 4203/202RS bearings can be traced back to the early 20th century, with the emergence of ball bearings as a revolutionary innovation in mechanical engineering. Over time, bearing technology has undergone significant advancements, leading to the development of more sophisticated and efficient bearings like 4203/202RS.

- 1. Precision Dimensions The 6205 bearing features precise internal and external diameters, as well as a consistent width, which contribute to its smooth operation and long service life. These dimensions are crucial for maintaining proper alignment and reducing wear between the bearing and its mating parts.

- The 6311 bearing is a reliable and efficient component that plays a vital role in many industrial applications. By following the maintenance tips outlined in this article, you can help ensure the longevity and optimal performance of this important bearing.

- The 6302 bearing is widely used in various applications due to its versatility and reliability. It is commonly found in automotive engines, transmissions, and differentials It is commonly found in automotive engines, transmissions, and differentials

It is commonly found in automotive engines, transmissions, and differentials It is commonly found in automotive engines, transmissions, and differentials

It is commonly found in automotive engines, transmissions, and differentials It is commonly found in automotive engines, transmissions, and differentials 6302 bearing dimensions. In industrial machinery, it is used in pumps, fans, and conveyors. The bearing's ability to handle both radial and axial loads makes it suitable for applications where multiple forces act on the shaft.

6302 bearing dimensions. In industrial machinery, it is used in pumps, fans, and conveyors. The bearing's ability to handle both radial and axial loads makes it suitable for applications where multiple forces act on the shaft. - * Steel and aluminum production Bearings used in rolling mills, extruders, and other equipment in the steel and aluminum industries must be able to withstand high temperatures and corrosive environments.

- Material and Construction

- Understanding Tapered Wheel Bearings A Key Component in Automotive Engineering

- In addition to material advancements, the 6007 2rs bearing has also benefited from improvements in manufacturing processes

- The 33113X2 bearing is a crucial component in various industrial and mechanical systems. It is designed to withstand high loads and provide long-lasting performance in harsh operating conditions. In this article, we will delve into the features, benefits, and applications of the 33113X2 bearing, as well as provide tips for maintenance and troubleshooting.

- The 51113 bearing is known for its superior quality and durability. It is made from high-grade materials, such as chrome steel, which ensures excellent strength and resistance to wear and tear. The bearing's design includes precision ball bearings that reduce friction and heat generation, resulting in increased efficiency and longer life. Additionally, the bearing's cage is made from high-quality plastic, which provides stability and prevents the balls from coming into contact with each other, further reducing wear.

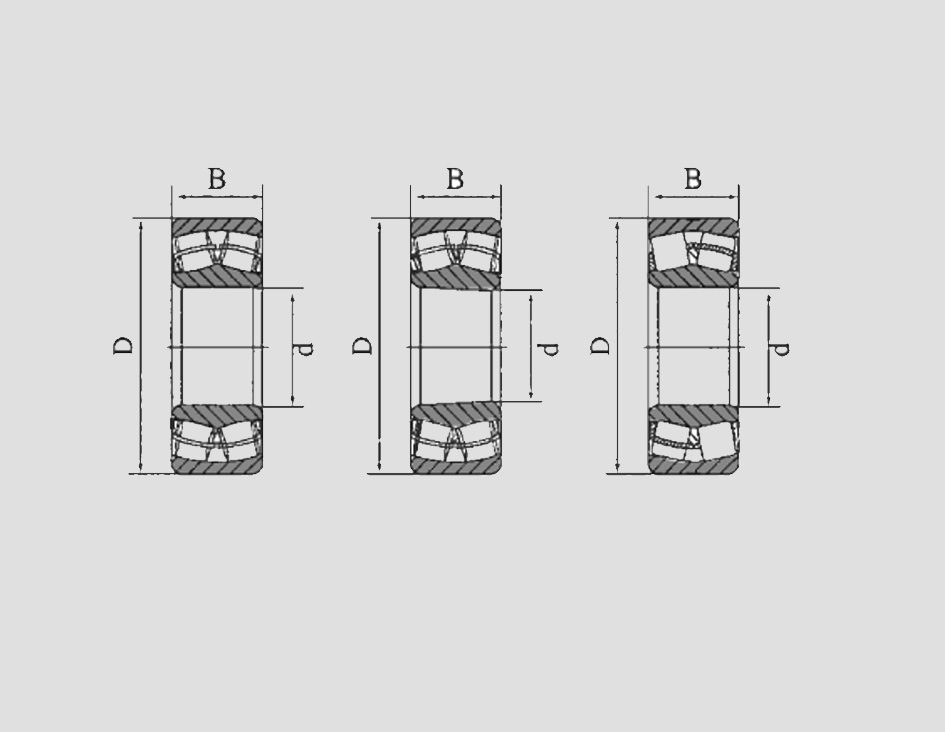

- Double row deep groove ball bearings consist of an outer ring, inner ring, and a cage that holds a set of balls between them. These bearings are designed with a deep groove in both the inner and outer rings, which provides stability and support to the balls during rotation. The width of the groove and the contact angle between the balls and the races determine the bearing's load capacity and stiffness.

- A bearing with a groove in the outer race is a type of bearing that is designed with a specially engineered groove in the outer ring or race, which allows for improved lubrication and performance. These bearings are commonly used in various industrial applications where high speeds and heavy loads are often encountered.

- Conclusion

- The year 2020 has been a year like no other, marked by unprecedented global events that have reshaped our lives in profound ways. From the initial shock of the COVID-19 pandemic to the ongoing social and political upheavals, 2020 has tested our resilience and forced us to adapt to new realities. In this article, we will explore some of the key themes and events that defined 2020, providing insights into the complex interplay of human behavior, technology, and globalization.

- Despite their robust nature, maintenance of cylindrical roller bearings is relatively straightforward. Regular lubrication, cleaning, and inspection can significantly prolong their service life. However, it's crucial to note that their suitability for a particular application depends on factors like load capacity, speed, and environmental conditions, necessitating careful selection and installation.

- Applications

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating

With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating With reduced friction comes increased mechanical efficiency, leading to lower energy consumption and longer operating cycles without overheating The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial The increased number of balls also ensures improved wear resistance and extends the service life of the bearing, especially in demanding applications where consistent performance is crucial

The thickness, or width, influences the bearing's load-carrying capacity The thickness, or width, influences the bearing's load-carrying capacity

The thickness, or width, influences the bearing's load-carrying capacity The thickness, or width, influences the bearing's load-carrying capacity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity

Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity Reduced downtime The ease of maintenance and long service life of flanged tapered roller bearings minimize downtime and increase productivity