fiberglass food grade equipment a closer look at its features and ...

...

2025-08-15 03:12

2198

...

1144

One of the key advantages of FRP flanges and blind is their excellent corrosion resistance

...

1548

The Fiberglass Clarifier System operates on a principle called sedimentation. As water flows through the system, suspended solids and impurities are encouraged to settle at the bottom of the tank due to gravity. The unique design of the fiberglass clarifier optimizes this process, allowing for a higher rate of clarification than conventional methods. The settled solids are then removed, leaving behind clean, clarified water.

...

2664

Keywords Drilling, YT29, Techniques, Implications, Industry Analysis

...

362

HEAVY DUTY FIBERGLASS GRATING

...

2434

One of the primary advantages of using fiberglass products in steel smelting plants is their ability to reduce heat loss. Fiberglass insulation can significantly reduce the amount of heat lost through the furnace walls, which in turn helps to conserve energy and reduce operating costs. This is particularly important in large steel smelting plants, where energy consumption can be a significant expense.

...

2162

Smooth Surface – Great for Bar Screens at Wastewater Treatment plants or Architectural applications

...

1408

Installation of fiberglass stack liners is often straightforward and cost-effective. Their lightweight nature facilitates easy handling and reduces the need for heavy machinery during installation. Moreover, they require minimal maintenance, further contributing to their overall cost-effectiveness.

...

1243

One of the key advantages of using frp weirs is their high strength-to-weight ratio. Frp materials are lightweight yet incredibly strong, making them ideal for use in water control structures where weight is a concern. Unlike traditional materials like concrete or steel, frp weirs are easy to transport, install, and maintain, saving time and resources for industries.

...

1283

...

1144

One of the key advantages of FRP flanges and blind is their excellent corrosion resistance

...

1548

The Fiberglass Clarifier System operates on a principle called sedimentation. As water flows through the system, suspended solids and impurities are encouraged to settle at the bottom of the tank due to gravity. The unique design of the fiberglass clarifier optimizes this process, allowing for a higher rate of clarification than conventional methods. The settled solids are then removed, leaving behind clean, clarified water.

...

2664

Keywords Drilling, YT29, Techniques, Implications, Industry Analysis

...

362

HEAVY DUTY FIBERGLASS GRATING

...

2434

One of the primary advantages of using fiberglass products in steel smelting plants is their ability to reduce heat loss. Fiberglass insulation can significantly reduce the amount of heat lost through the furnace walls, which in turn helps to conserve energy and reduce operating costs. This is particularly important in large steel smelting plants, where energy consumption can be a significant expense.

...

2162

Smooth Surface – Great for Bar Screens at Wastewater Treatment plants or Architectural applications

...

1408

Installation of fiberglass stack liners is often straightforward and cost-effective. Their lightweight nature facilitates easy handling and reduces the need for heavy machinery during installation. Moreover, they require minimal maintenance, further contributing to their overall cost-effectiveness.

...

1243

One of the key advantages of using frp weirs is their high strength-to-weight ratio. Frp materials are lightweight yet incredibly strong, making them ideal for use in water control structures where weight is a concern. Unlike traditional materials like concrete or steel, frp weirs are easy to transport, install, and maintain, saving time and resources for industries.

...

1283

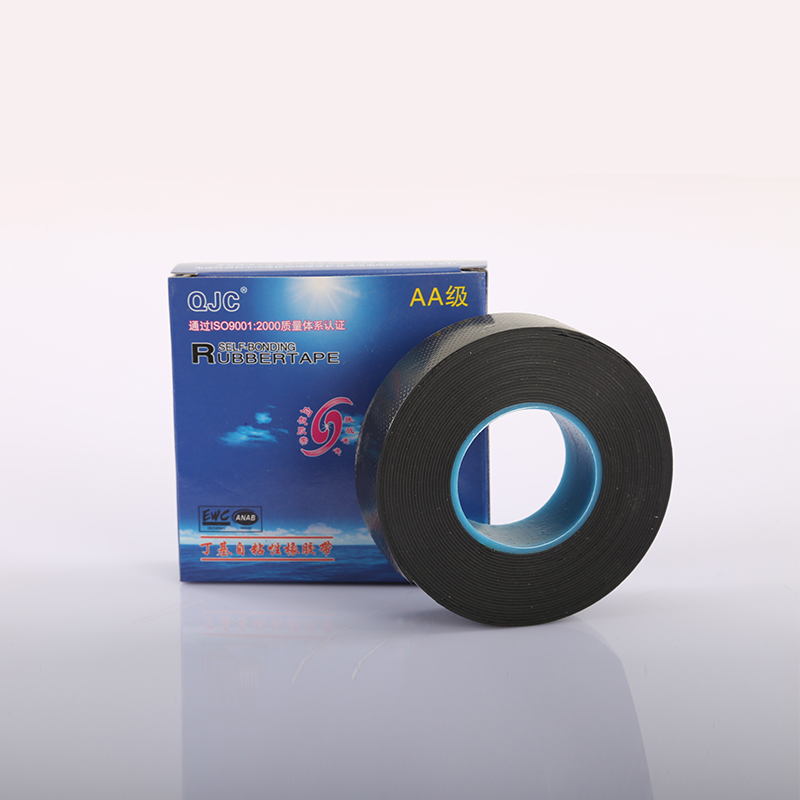

**Electrical Conductivity** The semi-conductive layer ensures that electrical current can flow smoothly along the cable, minimizing the risk of interference or damage to connected devices **Electrical Conductivity** The semi-conductive layer ensures that electrical current can flow smoothly along the cable, minimizing the risk of interference or damage to connected devices

**Electrical Conductivity** The semi-conductive layer ensures that electrical current can flow smoothly along the cable, minimizing the risk of interference or damage to connected devices **Electrical Conductivity** The semi-conductive layer ensures that electrical current can flow smoothly along the cable, minimizing the risk of interference or damage to connected devices Its ability to withstand a broad temperature range (-10°C to 60°C) ensures reliable performance under varying environmental conditions Its ability to withstand a broad temperature range (-10°C to 60°C) ensures reliable performance under varying environmental conditions

Its ability to withstand a broad temperature range (-10°C to 60°C) ensures reliable performance under varying environmental conditions Its ability to withstand a broad temperature range (-10°C to 60°C) ensures reliable performance under varying environmental conditions