It was not until the development of the hydraulic drifter in the 1950s that rock drilling truly entered the modern era

When selecting a commercial upholstery sewing machine, consider the following factors

Typically, the machine head employs methods such as stitching, heat sealing, or gluing to close the bags. Each method has its advantages depending on the type of bag and the contents that need protection. For example, heat sealing is particularly effective for plastic bags as it provides a strong and waterproof closure. On the other hand, stitching is suitable for fabric bags, delivering durability and resistance against tearing during transport.

Serger machines offer a range of stitching options that traditional sewing machines do not. Beyond basic overlocking, users can create rolled hems, which are particularly useful for lightweight fabrics, and flatlock stitches, which are great for joining seams. Many sergers also have the capability to perform coverstitching, which is often used in the hems of T-shirts and activewear. This versatility allows sewists to tackle various projects, from simple alterations to complex garments.

Benefits for Manufacturers

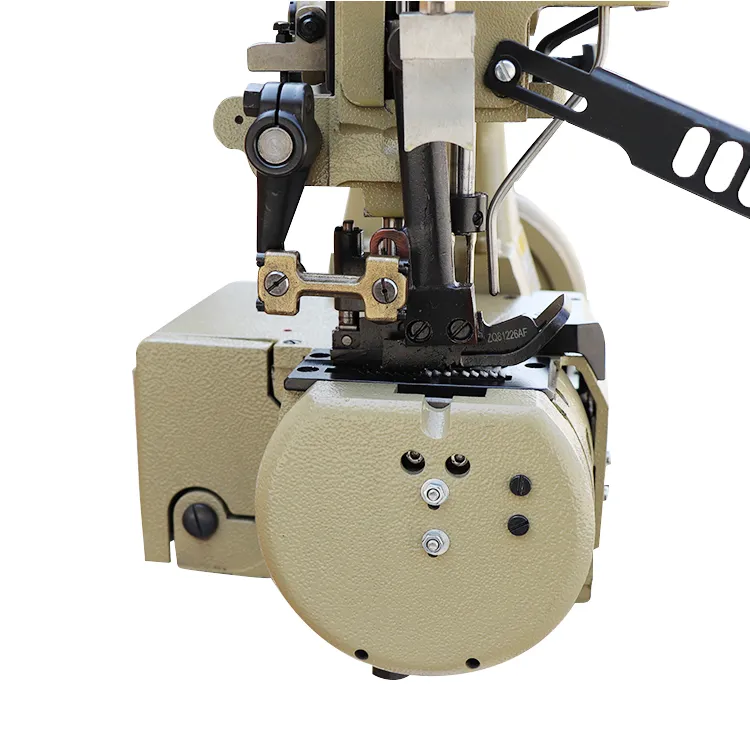

automatic shoe sewing machine

One of the primary advantages of using a double needle lockstitch machine is the efficiency it brings to production processes

. By sewing two lines of stitches at once, manufacturers can significantly reduce the time required for assembly, which translates to increased productivity. Furthermore, the machine's ability to create consistent and secure seams minimizes the need for post-sewing corrections, thereby streamlining the entire manufacturing workflow.To practice your new skills, start with simple projects like

Advantages of Heavy-Duty Sewing Machines

4. Leather Goods

The presser foot is a crucial component that can elevate your sewing projects from basic to exceptional. By utilizing specialized presser feet, you can tackle a wide range of techniques, from creating buttonholes to intricate quilting designs. As you gain experience and confidence in your sewing abilities, consider expanding your collection of presser feet to unlock new possibilities and fully embrace the art of sewing. Each foot is a tool that allows for creativity and precision, ensuring your sewing journey is as rewarding as it is productive.

Features of the Single Needle Edge Cutter Machine

In conclusion, the two needle stitch is not only a functional technique but also an opportunity for creativity in sewing. Its ability to provide durability while incorporating aesthetic elements makes it a favorite among both professionals and hobbyists alike. By mastering this stitch, sewists can elevate their projects, crafting garments and home furnishings that are as stylish as they are sturdy. With practice and patience, anyone can harness the art of the two needle stitch and incorporate it into their sewing repertoire.

In a world where sewing has become more than just a necessity, the zigzag sewing machine stands out as a remarkable tool for creativity and efficiency. Its diverse features and wide-ranging applications make it a staple in sewing rooms around the globe. Whether you are a novice exploring the world of sewing or an experienced artisan pushing the boundaries of your craft, a zigzag sewing machine is an essential ally in bringing your visions to life. With this machine, the possibilities are truly endless, making sewing a fulfilling and enjoyable endeavor.

Taking care of heavy canvas products ensures their longevity. Most heavy canvas is machine washable, but it's crucial to follow the manufacturer’s care instructions. To maintain the strength and color of the fabric, wash in cold water and avoid bleach. If the item is exposed to harsh outdoor conditions, consider using a fabric protector to repel dirt and water.

2. Double-Needle Stitching Machines Suitable for heavier fabrics, these machines provide stronger stitching lines, increasing the durability of the bags.

- Needle Positioning The ability to adjust needle positions can enhance the functionality and the types of projects that can be undertaken. Some machines offer various needle spacing options to accommodate different styles of sewing.

In the world of textiles and garment manufacturing, the sewing machine has long been a cornerstone of the industry. Among the various types of sewing machines, the needle feed sewing machine stands out for its ability to enhance efficiency, accuracy, and versatility in fabric handling. This article explores the features, benefits, and applications of needle feed sewing machines, highlighting their significance in modern textile production.

Compact Design:

In the landscape of textile production, the evolution of sewing technology has had a profound impact on efficiency, creativity, and quality. Among the myriad of sewing machines available today, the modern chain stitch machine stands out as a key player. This innovative machine not only enhances the speed of production but also elevates the quality of finishing in garment manufacturing, making it an indispensable tool in the fashion and textile industries.

1. Increased Efficiency Automation reduces the time it takes to seal bags, allowing for faster production rates and minimizing labor costs. In high-demand settings, this can be a game changer for meeting tight deadlines.

plastic bag closer machine

Twin needle sewing is not limited to decorative purposes; it also plays a vital role in practical applications. For instance, sewing elastic into garments often benefits from the twin needle technique. It creates secure, flexible seams that allow garments to stretch and move comfortably. Similarly, when working on various sewing projects like curtains or tablecloths, a twin needle can ensure that seams are reinforced while adding a polished finish.

The presser foot is a crucial component that can elevate your sewing projects from basic to exceptional. By utilizing specialized presser feet, you can tackle a wide range of techniques, from creating buttonholes to intricate quilting designs. As you gain experience and confidence in your sewing abilities, consider expanding your collection of presser feet to unlock new possibilities and fully embrace the art of sewing. Each foot is a tool that allows for creativity and precision, ensuring your sewing journey is as rewarding as it is productive.

Understanding Zig Zag Embroidery

3. Brand Reputation Research brands known for their reliability and support. Popular brands often have established service networks, which can be crucial for maintenance and repairs.

Incorporating a twin needle into your sewing routine can elevate your project designs dramatically. By using different colors of thread for each needle, you can create stunning decorative effects. This technique is especially popular in quilting, embroidery, and crafts, where adding a splash of color can bring an otherwise simple project to life.

Key Applications of Cylinder Arm Sewing Machines

Applications in the Garment Industry

A lockstitch sewing machine creates a stitch by interlocking a top thread and a bobbin thread. The top thread, which is fed from a spool, is threaded through a needle, while the bobbin thread is wound into a small spool that sits underneath the needle plate. As the needle penetrates the fabric, it carries the top thread down, creating a loop which the bobbin thread catches. As the needle ascends, the two threads interlock, forming a secure stitch. This simple yet effective mechanism is what makes lockstitch machines popular and indispensable in numerous sewing applications.