Find out what type of electrical tape you need based on your job.

2. Color Coding Wires In larger projects with numerous wires, red insulation tape can be employed for color coding. This method simplifies identification and troubleshooting, saving time and reducing errors.

One of the primary functions of insulation tape is to provide electrical safety. Made from materials that are resistant to electrical currents, yellow insulation tape is commonly used to insulate wires and connections, ensuring safety in electrical installations. Its bright color allows for easy identification and differentiation between various electrical circuits. For safety professionals and electricians, yellow tape often signifies caution or a specific type of wiring, making it an essential tool for clear communication and safety protocol adherence.

Price is an important factor when choosing a control box because there are many that are cheap but are also faulty.

We all know that electrical tape is an important part of any electrical job. But what many people don’t know is what temperature does electrical tape melt?

Hydraulic Control Boxes

floor marking yellow tape. Its bright color grabs attention, making it an effective visual tool in various environments. It not only enhances workplace safety but also promotes order and efficiency, demonstrating the power of color-coded communication in our daily lives.

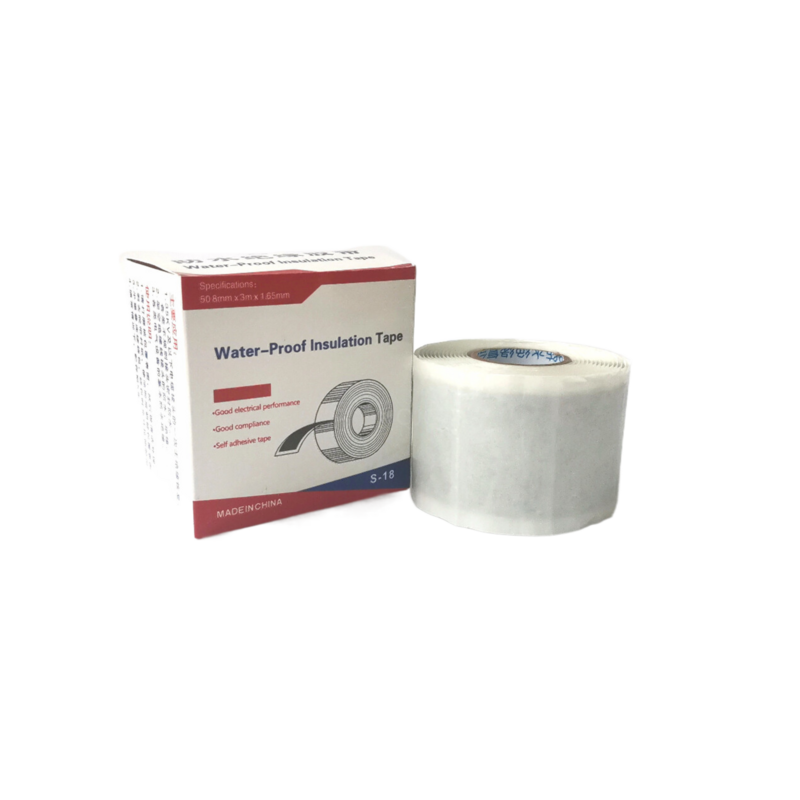

floor marking yellow tape. Its bright color grabs attention, making it an effective visual tool in various environments. It not only enhances workplace safety but also promotes order and efficiency, demonstrating the power of color-coded communication in our daily lives.Self-fusing silicone electrical tape represents a significant advancement in electrical insulation technology. Its combination of high-temperature resistance, water and chemical resilience, and self-adhering properties makes it an ideal choice for a wide array of applications. Whether for professional use in industrial settings or handy DIY repairs at home, self-fusing silicone tape provides a reliable and effective solution for protecting and insulating electrical components. As awareness of its benefits grows, it is likely that this innovative product will continue to gain popularity among electricians and gardeners alike, effectively redefining the standards for electrical insulation.