Waterproof Sheets To protect mattresses from bodily fluids and ensure hygiene, hospitals employ waterproof or moisture-resistant sheets Waterproof Sheets To protect mattresses from bodily fluids and ensure hygiene, hospitals employ waterproof or moisture-resistant sheets

Waterproof Sheets To protect mattresses from bodily fluids and ensure hygiene, hospitals employ waterproof or moisture-resistant sheets Waterproof Sheets To protect mattresses from bodily fluids and ensure hygiene, hospitals employ waterproof or moisture-resistant sheets types of bed sheets used in hospital. These are typically made from materials like vinyl, TPU (thermoplastic polyurethane), or polyester with a waterproof backing. While they prevent liquid penetration, they should be designed to allow air circulation to avoid skin maceration.

types of bed sheets used in hospital. These are typically made from materials like vinyl, TPU (thermoplastic polyurethane), or polyester with a waterproof backing. While they prevent liquid penetration, they should be designed to allow air circulation to avoid skin maceration.Hospital Sheet Sets

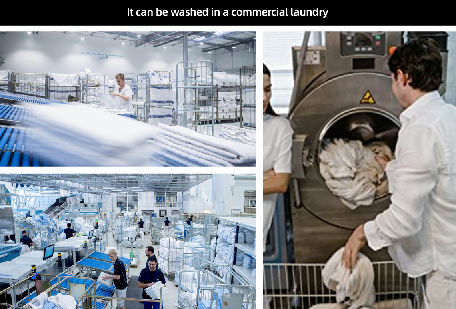

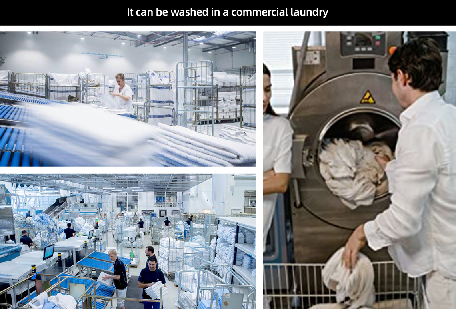

akemi microfibre pillow. Its easy-to-clean surface further adds to its practicality, as regular washing does not compromise its softness or shape retention. The pillow maintains its original plumpness even after multiple washes, ensuring long-lasting comfort.

akemi microfibre pillow. Its easy-to-clean surface further adds to its practicality, as regular washing does not compromise its softness or shape retention. The pillow maintains its original plumpness even after multiple washes, ensuring long-lasting comfort. They are often made from cotton or a blend of cotton and polyester, which are breathable and durable They are often made from cotton or a blend of cotton and polyester, which are breathable and durable

They are often made from cotton or a blend of cotton and polyester, which are breathable and durable They are often made from cotton or a blend of cotton and polyester, which are breathable and durable 35cm deep fitted sheets. These materials are gentle on the skin and can help regulate body temperature, keeping you cool and comfortable throughout the night.

35cm deep fitted sheets. These materials are gentle on the skin and can help regulate body temperature, keeping you cool and comfortable throughout the night.

Cotton is a plant that loves warmer weather and it takes several months for it to produce the fluffy cotton balls that we all know. After the plants are harvested, they are defoliated and send to the cotton gin. There, the cotton fibers are combed — this is done for cleaning and fiber straightening purposes — and then spun into yarn.

The 19th century saw the invention of the cotton gin. This machine quickly and easily separates cotton fibres from their seeds which revolutionised cotton production. Thus, the cotton sheet was born. This was the start of a new industry. It became much easier to produce cotton than flax and that in turn made it a cheaper product. Ultimately cotton became the popular choice for bedding, though the name bed linen stuck.

bed cover design. A well-designed cover can influence our mood, promoting relaxation after a long day or energizing us in the morning. It can make a small room appear larger, a dull room brighter, or a sophisticated room more intimate. Moreover, they allow for easy room makeovers without major renovations, simply by swapping out covers according to seasons, moods, or events.

bed cover design. A well-designed cover can influence our mood, promoting relaxation after a long day or energizing us in the morning. It can make a small room appear larger, a dull room brighter, or a sophisticated room more intimate. Moreover, they allow for easy room makeovers without major renovations, simply by swapping out covers according to seasons, moods, or events.Production lines employing artificial intelligence technology enable intelligent sorting and quality inspection of fibers, greatly elevating the level of automation. Through intelligent management systems, enterprises can precisely monitor various indicators during the production process, maximizing resource utilization.

Cotton:Cotton is one of the most popular materials for sheets, either used by itself or in a blended fabric (meaning it contains two or more materials). Cotton is a natural, fluffy fiber that grows on the cotton plant. It is highly valued for being durable, breathable, and soft.

cool touch comforter. Its sleek design and premium finish add a touch of sophistication to any bedroom decor. It is available in various colors and patterns, allowing individuals to personalize their sleep space according to their style preferences.

cool touch comforter. Its sleek design and premium finish add a touch of sophistication to any bedroom decor. It is available in various colors and patterns, allowing individuals to personalize their sleep space according to their style preferences. 28cm fitted sheet. Machine washable and often wrinkle-resistant, these sheets make laundry days a breeze. They retain their shape and color well, ensuring long-lasting use.

28cm fitted sheet. Machine washable and often wrinkle-resistant, these sheets make laundry days a breeze. They retain their shape and color well, ensuring long-lasting use.In addition to the yarn count, the hotel sheets fabric used is also crucial. Cotton is the most popular choice for hotel sheets because of its breathability, softness, and durability. Egyptian or Pima cotton is often favored for its long fibers, which make hotel sheets finer, smoother, and more luxurious. Not only are these high-quality cotton hotel sheets comfortable, they stand up to frequent washing and retain their softness over time.