The impact of Grp vessels extends beyond functionality and into the realm of aesthetics

- In factories and warehouses, floor tape serves as a silent sentinel, outlining pathways, demarcating storage zones, and designating emergency exits. It's a visual language understood by all, warning workers about potential dangers and guiding them through orderly operations. The bright yellow stripes act as a beacon, alerting personnel to stay clear of machinery or designated danger zones, thereby preventing accidents and ensuring workplace safety.

But there are some types that can withstand temperatures up to 200°C.

- Insulation black tape is available in different widths and thicknesses, allowing users to choose the perfect size for their specific application. Its easy-to-use nature makes it a popular choice among professionals who require a quick and convenient solution for insulation tasks.

- In addition to its practical uses, Flex Tape is also a popular choice for craft projects. The tape can be cut into different shapes and sizes, making it easy to customize for your specific needs. Whether you're creating a DIY wallet, repairing a torn tent, or adding a waterproof seal to a homemade project, Flex Tape can help you get the job done.

- Properly labelled components, wiring, and terminals are essential for proper maintenance.

The ease of application is another factor that makes insulation cotton tape highly desirable among professionals and DIY enthusiasts alike. It is lightweight, flexible, and can be easily cut to size, allowing for a seamless application process. Unlike rigid insulation materials, cotton tape can easily conform to various shapes and surfaces, making it ideal for intricate or irregular installations.

floor marking tape. It designates storage zones, outlines forklift lanes, and creates buffer zones around racking systems, promoting a safer and more streamlined operational environment.

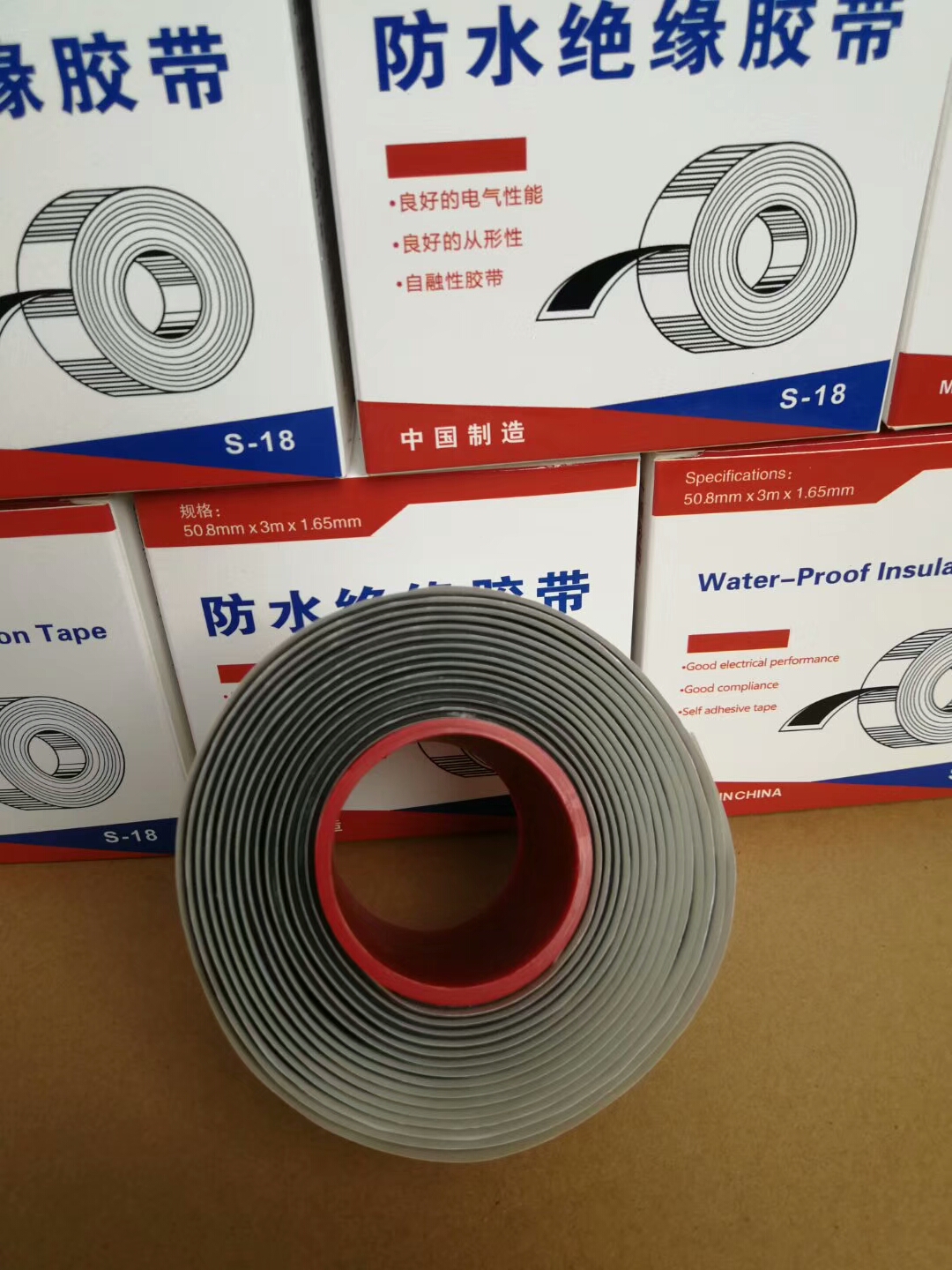

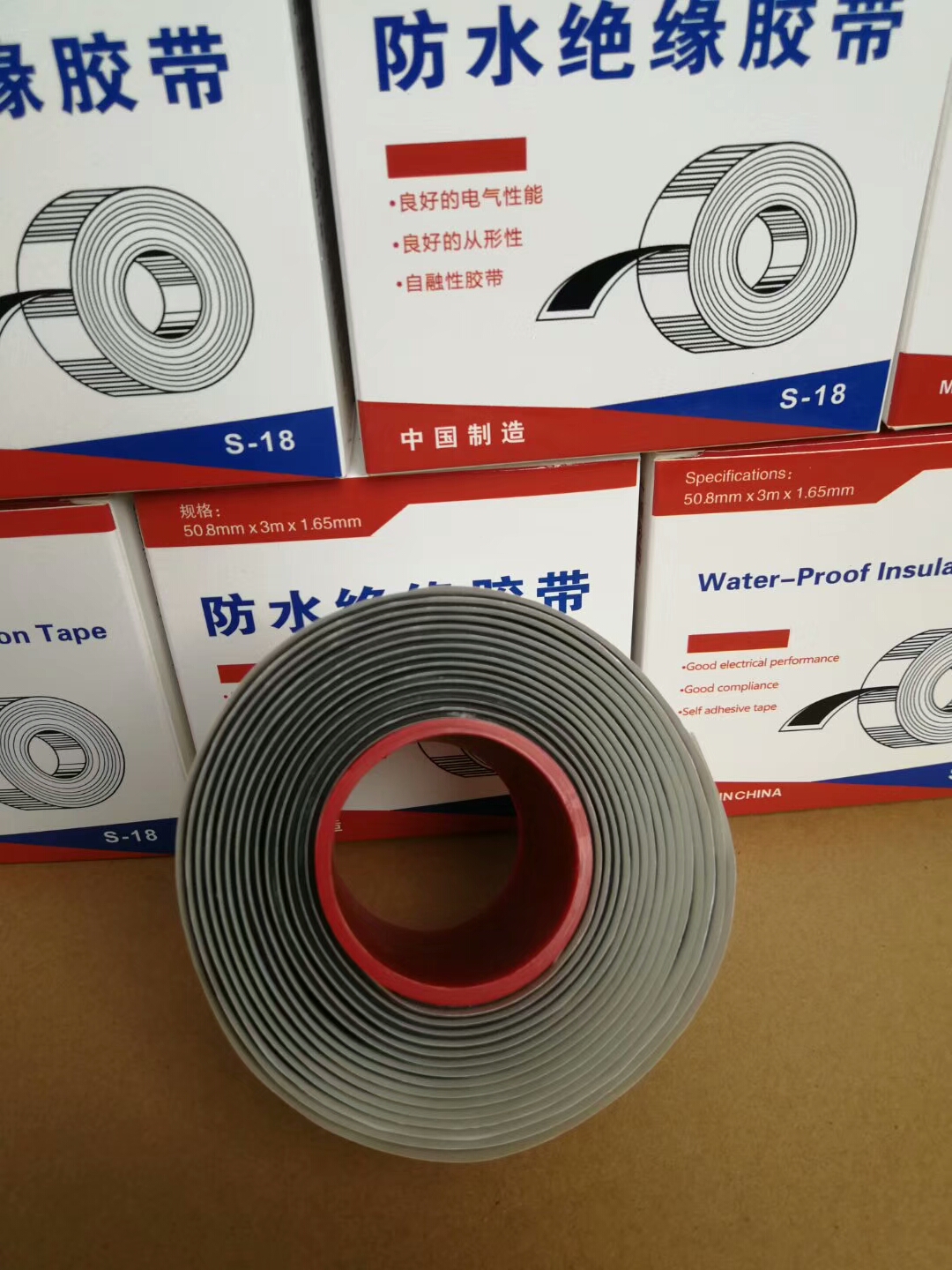

floor marking tape. It designates storage zones, outlines forklift lanes, and creates buffer zones around racking systems, promoting a safer and more streamlined operational environment.One of the primary factors affecting the price of insulation tape is the quality of the materials used in its manufacturing. Insulation tapes can be made from various substances, including PVC (Polyvinyl Chloride), rubber, or cloth. Generally, PVC insulation tapes are the most common and are widely used due to their cost-effectiveness and reliability. However, higher-quality materials, such as rubber-based adhesives or more robust cloth tapes, may come at a premium. The complexity of the material and its ability to withstand heat, cold, or moisture can significantly influence the price.

Size: 3m x 25mm (0.5mm thick)

Construction Integrity

The Advantages of Silicone Self-Adhesive Tape

The tape's thickness and backing materials are often customizable, catering to specific application requirements The tape's thickness and backing materials are often customizable, catering to specific application requirements

The tape's thickness and backing materials are often customizable, catering to specific application requirements The tape's thickness and backing materials are often customizable, catering to specific application requirements high speed splicing tape.

high speed splicing tape.The Importance of Red and White Floor Marking Tape

In conclusion, black PVC electrical tape is more than just a simple roll of tape; it is an essential tool with a multitude of applications. Its durability, versatility, and ease of use make it a preferred choice for professionals and DIY enthusiasts alike. Whether you are insulating wires, securing connections, or embarking on a creative project, black PVC electrical tape proves to be a reliable ally, ensuring safety and functionality in every electrical endeavor. As you venture into your next project, don’t underestimate the power of this unsung hero of the toolbox.

3M rubber tapes have operating temperatures ranging from 176°F (80°C) to 221°F (105°C). Some, Linerless Rubber Splicing Tape 130C and Rubber Splicing Tape 23, have overloads temperatures up to 266°F (130°C). Because of this high heat attribute; there are many industrial settings where it is common to use rubber tape in lower voltage applications to moisture seal, pad and insulate:

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.

self vulcanizing tape. It is employed to repair and protect pipes, tanks, and other structures from corrosion and damage. The tape's ability to adhere tightly to various surfaces, even in the presence of moisture or extreme temperatures, makes it an invaluable asset for contractors and maintenance personnel.