Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition

Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition Additionally, these tapes are often coated with a fire-retardant chemical that helps to slow down the spread of flames and reduce the risk of ignition flame resistant tape.

flame resistant tape.Fire seal tape is a critical yet often underappreciated component in the realm of fire safety and construction. Its ability to seal gaps effectively, enhance fire resistance, and ensure compliance with safety regulations makes it indispensable in modern building practices. As the construction industry continues to prioritize safety and efficiency, the correct use of fire seal tape will remain a key factor in protecting lives and properties from the devastating effects of fire. Investing in quality fire seal tape and ensuring its proper installation is a responsible choice for builders, architects, and property owners alike.

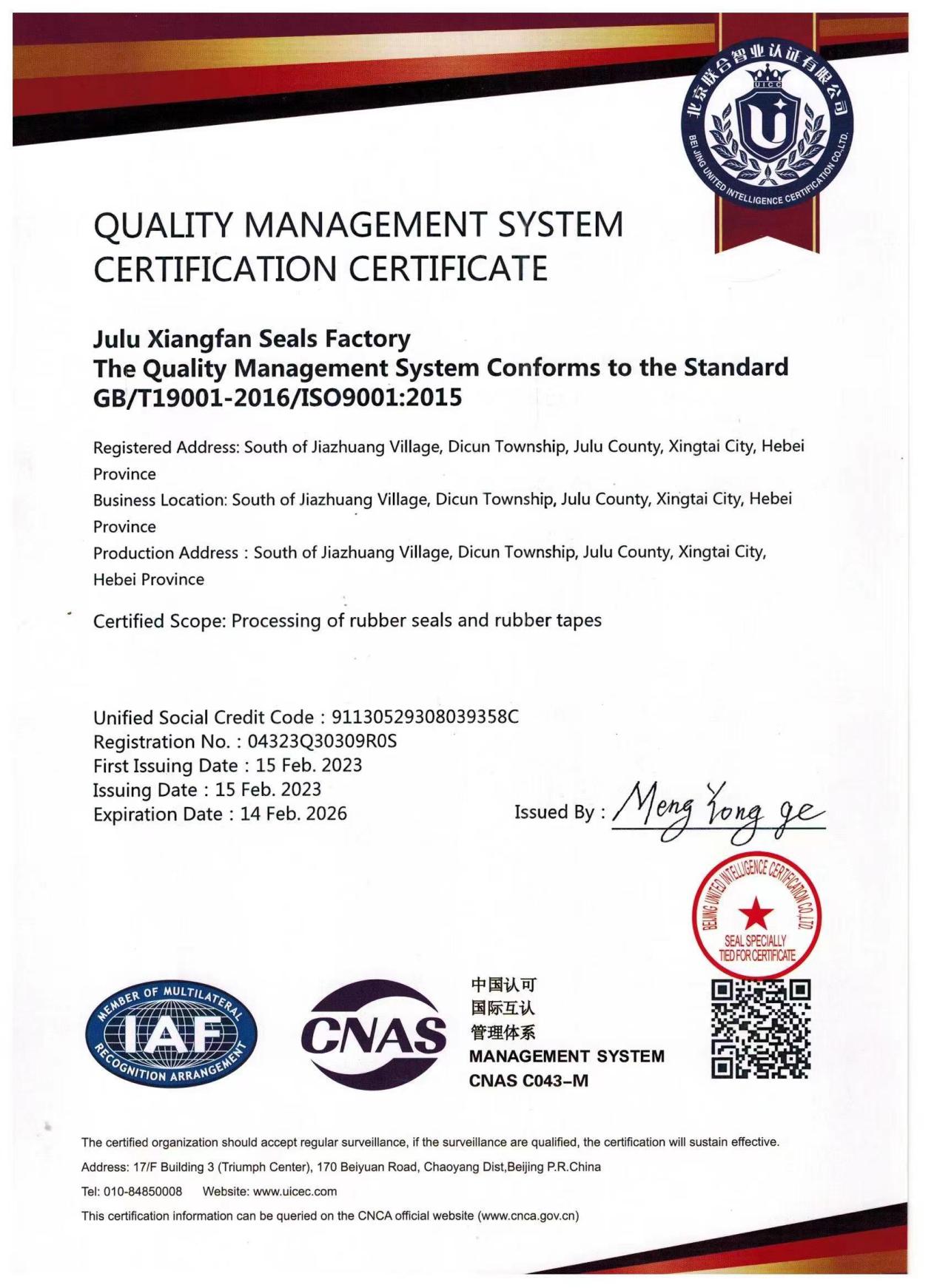

Quality Assurance: certifications and quality standards ensure that you're investing in a reliable and effective product.

Here at Swift, we stock a number of different electrical tapes. Some are adhesive, some are not and somewhere in the middle are our self-fusing tapes. These don't stick to surfaces but they do stick to themselves.

It’s common for well control box installers to carry multi-purpose control boxes with them so they can install one at any job site. This sometimes results in the consumer paying more for something they don’t need.

You should use a minimum of two half-lapped layers of vinyl tape to insulate and jacket low-voltage components. A half-lap (see Figure above) consists of overlaying each turn by one-half the width of the tape. The general rule of thumb calls for a tape thickness of 1.5 times the thickness of existing wire or cable insulation. In every case, tension on the tape should be sufficient to conform the tape evenly to the surface. A slight reduction in tension is encouraged for the final wrap. Trim the tape end and allow it to return to shape before pressing down with the thumb to avoid lifting or flagging.

automotive wire wrap tape. The tape is typically self-adhesive, allowing for quick and hassle-free application to the wiring harnesses. It can also be easily removed without leaving behind any sticky residue or damaging the wires, making it a convenient and versatile solution for automotive wiring projects.

high tension tape. In aerospace, it is used for cable management, holding together lightweight components, and securing equipment in place during flights. The automotive industry utilizes it for similar purposes, particularly in the assembly of cars, where precision and strength are crucial.

high tension tape. In aerospace, it is used for cable management, holding together lightweight components, and securing equipment in place during flights. The automotive industry utilizes it for similar purposes, particularly in the assembly of cars, where precision and strength are crucial. butyl foil tape. Its electrical non-conductivity, combined with its adhesive strength, makes it suitable for insulating wires and cables, protecting them from environmental damage. It's also used for splicing, grounding, and shielding applications.

butyl foil tape. Its electrical non-conductivity, combined with its adhesive strength, makes it suitable for insulating wires and cables, protecting them from environmental damage. It's also used for splicing, grounding, and shielding applications. It also has excellent resistance to abrasion, chemicals, and UV light, making it suitable for both indoor and outdoor use It also has excellent resistance to abrasion, chemicals, and UV light, making it suitable for both indoor and outdoor use

It also has excellent resistance to abrasion, chemicals, and UV light, making it suitable for both indoor and outdoor use It also has excellent resistance to abrasion, chemicals, and UV light, making it suitable for both indoor and outdoor use

It can also deter pests and dust, ensuring a cleaner living or working space It can also deter pests and dust, ensuring a cleaner living or working space

It can also deter pests and dust, ensuring a cleaner living or working space It can also deter pests and dust, ensuring a cleaner living or working space