types of jackhammers

Another notable feature is their durability. Fiberglass ducts are resistant to corrosion, unlike metal ducts that can rust over time. They also withstand extreme temperatures, making them suitable for both heating and cooling applications. Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance

Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance Their non-porous surface resists dust accumulation, contributing to cleaner air quality and less frequent maintenance fiberglass duct.

fiberglass duct.

In conclusion, fiberglass water tanks have revolutionized the way we store and manage water resources. Their combination of strength, durability, adaptability, and environmental friendliness has solidified their position as a preferred choice for modern water storage solutions. As technology advances and sustainability becomes a priority, it is expected that the use of fiberglass water tanks will continue to grow, contributing to more efficient and eco-conscious water management practices worldwide.

Fiberglass tanks represent a testament to human innovation, providing a versatile solution to complex storage needs. Their blend of strength, adaptability, and cost-effectiveness continues to make them a preferred choice across a wide spectrum of industries. As technology advances, the applications for fiberglass tanks are likely to expand, further cementing their status as an essential tool in modern industrial processes.

Firstly, the type of jack hammer plays a crucial role in determining its price. There are two main types electric and pneumatic. Electric models are generally more affordable and easier to operate, but they may lack the raw power and durability of their pneumatic counterparts. Pneumatic jack hammers, fueled by compressed air, offer greater strength and longevity, which reflects in their higher price point.

There are several types of rock drill button bits available, each designed for specific rock formations and drilling conditions. For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations

For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations For example, dome-shaped buttons are ideal for hard and abrasive rock formations, while conical buttons are better suited for softer formations rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity.

rock drill button bit. By selecting the right type of button bit for the job, drillers can optimize their drilling efficiency and productivity.

The main advantage of retrac bits is their versatility. They can be used in a wide range of drilling conditions, from soft to hard rock formations. This flexibility makes them a popular choice among drillers who need to adapt to different geological conditions quickly.

Fiberglass, composed primarily of silica, possesses an innate resistance to chemical attack. When combined with a corrosion-resistant resin, such as epoxy or polyester, it forms a formidable barrier against corrosive substances. The matrix shields the glass fibers from direct contact with harsh environments, thereby enhancing the material's durability.

In addition to being corrosion-resistant, fiberglass reinforced pipes are also lightweight and easy to install. This makes them a cost-effective option for many applications, as they can be transported, handled, and installed with minimal equipment and manpower. The flexibility of FRP pipes also allows for easier customization, with the ability to create pipe systems in various sizes, shapes, and configurations to meet specific project needs.

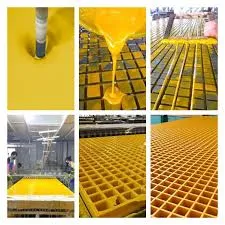

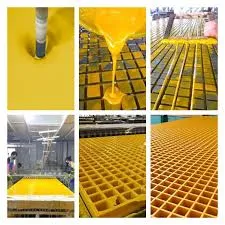

1.Fiberglass gating cover plate

The anti slip performance can be show out only in fiberglass gating cover plate, such as grid sand covered and Striped grating. The appearance of Fiberglass gating cover plate can be smooth, nonslip paving sand surface is probably slip markings, cover plate thickness usually 4.0cm. It can also used according to Customer credentials size, which often use in a closed area for sewage disposal punishment measures and prevent gas spillover. Anti slide grating cover can also be used as a ramp, manhole cover and trench cover.

The anti slip performance can be show out only in fiberglass gating cover plate, such as grid sand covered and Striped grating. The appearance of Fiberglass gating cover plate can be smooth, nonslip paving sand surface is probably slip markings, cover plate thickness usually 4.0cm. It can also used according to Customer credentials size, which often use in a closed area for sewage disposal punishment measures and prevent gas spillover. Anti slide grating cover can also be used as a ramp, manhole cover and trench cover.