Sa huli, ang galvanized walkway ay hindi lamang isang simpleng daanan; ito ay isang simbolo ng pagsulong sa ating bisa at pananaw sa pagbuo ng mas ligtas at mas maginhawang lugar para sa lahat. Sa pagtutok natin sa mga ganitong inobasyon, tiyak na mapapalakas natin ang ating mga komunidad at mapapabuti ang kalidad ng buhay ng ating mga mamamayan. Kaya't sulit na isaalang-alang ang paggamit ng galvanized walkway sa mga proyekto sa hinaharap.

Exploring Metal Mesh Gratings Applications, Benefits, and Innovations

It is relatively low-maintenance because it does not require painting and further maintenance.

환경적인 측면에서도 갈바나이즈드 메탈 그레이트는 주목할 만한 장점이 있습니다. 아연은 재활용이 가능하여, 필요할 때마다 쉽게 새로운 제품으로 변환할 수 있습니다. 이러한 재활용 특성은 지속 가능한 건축과 제조에 기여하며, 환경 보호에도 이바지하고 있습니다.

안전 그물은 강력한 재질로 제작되어 헬리콥터의 무게를 견딜 수 있도록 설계되었습니다. 일반적으로 강철이나 특수 합성 섬유로 만들어지며, 내구성이 뛰어나고 기상 변화에도 견디는 특성이 있습니다. 또한, 그물의 설계는 헬리콥터의 착륙 각도와 연관되어 있어, 제때에 안정적으로 헬리콥터를 지탱할 수 있도록 최적화되어 있습니다.

Cast Iron Grates

The thickness of steel grating also plays a critical role in its applications. Typically, thickness ranges from 1/2 inch to 1 inch, with heavier grating often used in high-traffic areas or environments subject to heavy loads. For example, a 1-inch thick grating is ideal for industrial operations, where forklifts and trucks are common, while a 1/2 inch thick option may be sufficient for pedestrian walkways.

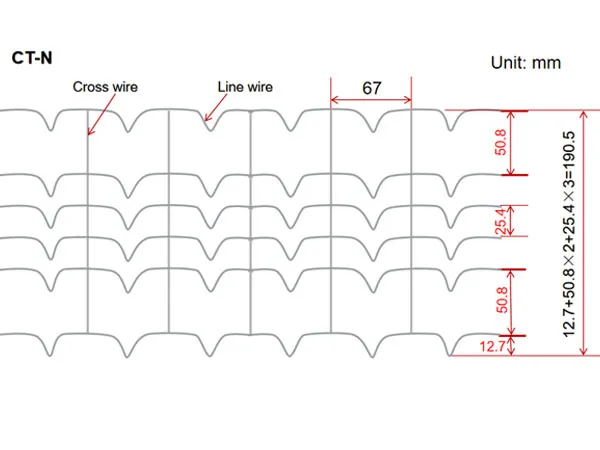

steel grating sizes

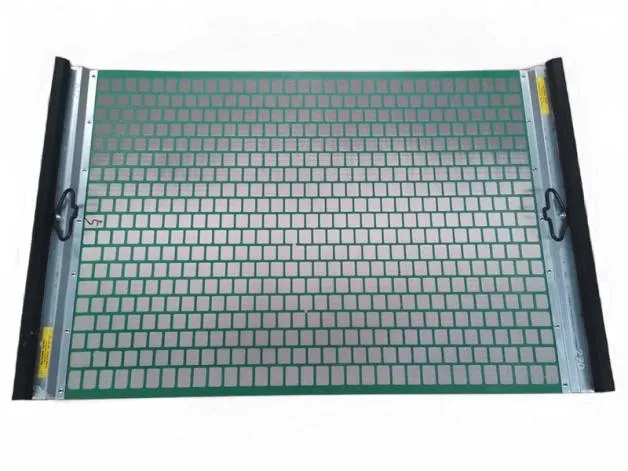

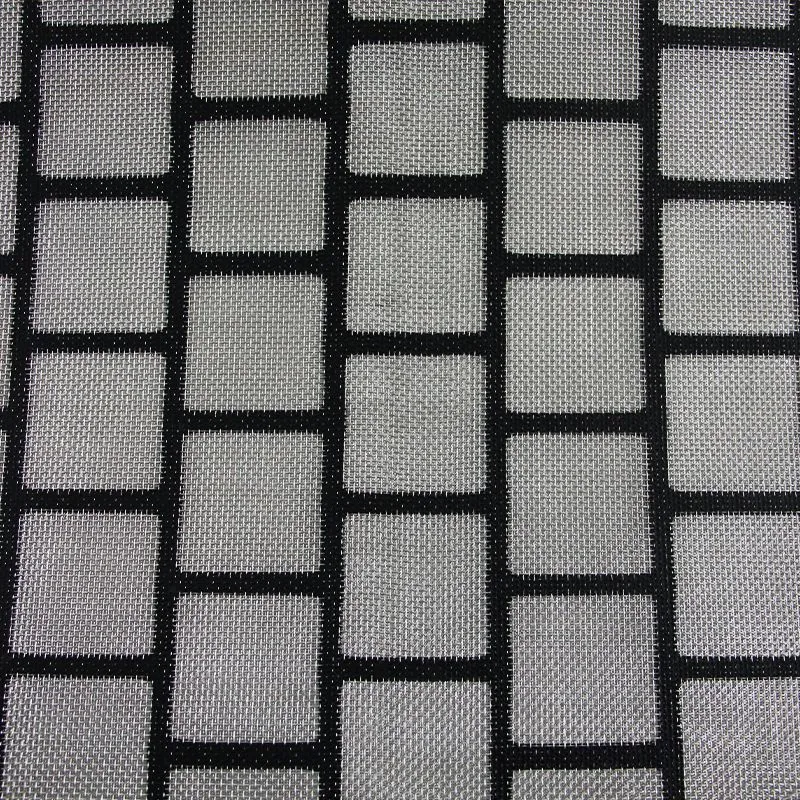

Shale shaker screens are critical in removing these solid particles from the drilling mud. By effectively separating the solids, shale shaker screens help maintain the desired properties of the mud, ensuring optimal drilling performance. Additionally, they contribute to environmental protection by reducing the discharge of solid waste into the environment.

Applications of 19% 204% Bar Grating

19 4 bar grating

はやにおいてなです。にのには、にをするがめられます。トレンチドレインは、そんなのなソリューションのつです。そして、メタルトレンチドレイングレートは、そのでもになとしてされています。

In conclusion, industrial floor grates are indispensable elements in modern industrial environments. They provide critical drainage capabilities, enhance safety, and contribute to the overall efficiency of operations. Understanding the features, materials, and installation guidelines of these components can help industries choose the right solutions for their specific needs, ultimately leading to a safer and more productive workplace.

The design of a grating usually involves considerations such as the material, the number of grooves per millimeter, the depth of the grooves, and the angle of incidence. In the case of 19w2% grating, the choice of material is critical. Common materials used for fabricating gratings include glass, quartz, and specialized polymers, each chosen based on the specific application. For ultraviolet applications, for instance, materials that absorb less in the UV range are preferred.

19w2 grating

このように、トレンチドレイングレートは現代の排水システムにおいて欠かせない存在であり、私たちの生活環境を快適に保つために重要な役割を果たしています。

Applications

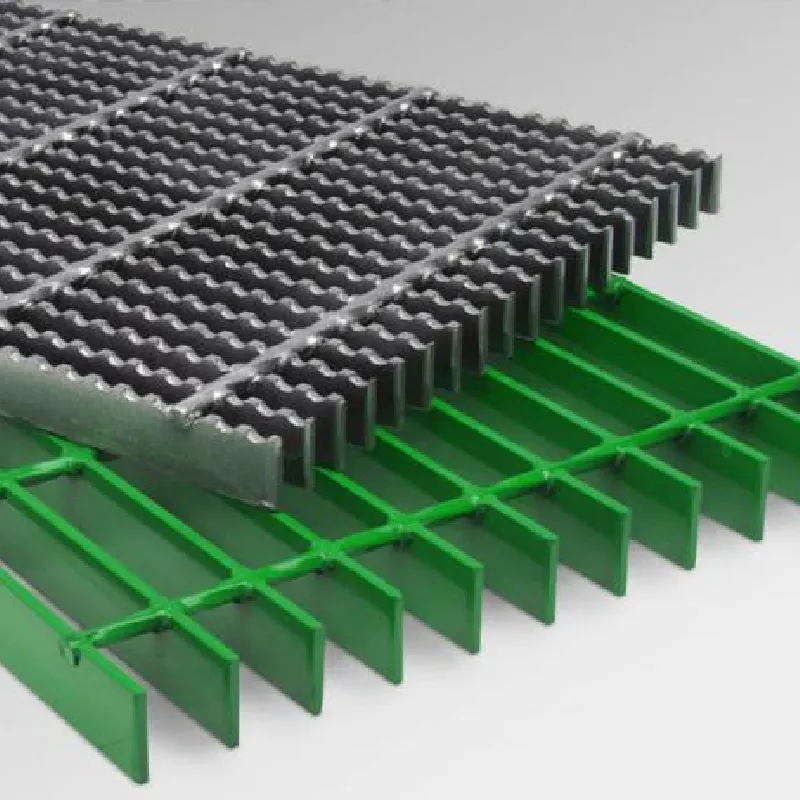

Hot dip galvanizing is a widely used method for coating steel to protect it from corrosion. This process involves immersing steel in molten zinc, which creates a thick, corrosion-resistant layer on the surface. When combined with grating, hot dip galvanized steel becomes an ideal solution for a variety of applications that require durability and strength.

Mesh Size: The mesh size of the screen determines the particle size that can be separated. Screens with smaller mesh sizes are effective in removing finer particles.

In conclusion, the importance of banded bar grating cannot be overstated. Its combination of strength, versatility, and aesthetic appeal makes it a preferred choice in various applications. As industries continue to evolve, the development and implementation of innovative banded bar grating solutions will likely remain at the forefront, enhancing safety and design in many environments.

Moreover, the versatility of heavy-duty steel grating cannot be overstated. It can be fabricated to various sizes and shapes, accommodating diverse project requirements. Customization options include different bar spacing and thicknesses, allowing for tailored solutions that meet specific load requirements and aesthetic considerations.

Environmental sustainability er også blevet en vigtig faktor i valget af materialer, og heavy duty steel grating er ikke en undtagelse. Mange producenter bruger genanvendt stål til at fremstille gitteret, hvilket hjælper med at reducere affald og energiforbrug under produktionen. Ved at vælge dette materiale kan virksomheder tage skridt mod at blive mere miljøvenlige.

Environmental sustainability is another significant factor to consider. Steel is highly recyclable, making steel grid walkways an eco-friendly choice. Many manufacturers use recycled materials in their products, contributing to a reduced carbon footprint. Investing in steel walkways aligns with the growing emphasis on sustainable practices in construction and infrastructure development.

L'acciaio inox satinato un'eccellenza nel design e nella funzionalità

Современные города сталкиваются с множеством проблем, связанных с управлением дождевыми водами. Для решения этой проблемы активно используются лотковые дренажные системы, которые помогают отводить избыточную воду и предотвращают затопления. Одним из ключевых компонентов этих систем являются пластиковые лотковые крышки.

2. Durability Made from robust materials, open floor grating can withstand heavy loads and harsh environmental conditions. This resilience is crucial for environments such as factories, warehouses, and outdoor areas where weather conditions can be unpredictable.

1. Mining and Mineral Processing Screens help separate ores from waste rock, increase recovery rates, and improve product purity.

Users can customize shaker screens with different mesh types, openings, and wire diameters depending on the material being processed. For instance, in the mining industry, screens can separate gravel, minerals, and other coarse materials, while finer screens are often used in wastewater treatment to remove small solids and particulates.

An industrial shaker screen is a type of separation equipment that uses vibration to distribute materials uniformly across the screening surface. This process enables the separation of particles into different sizes or classifications. The screens are typically made of wire mesh or perforated plates and can be configured in various shapes and sizes to accommodate specific application requirements.

ثانيًا، تُساهم تغطيات المصرف الخندقي في السلامة العامة. تعتبر الأسطح المبللة أو المغمورة بالمياه مصدر خطر للمارة، وقد تؤدي إلى حوادث وسقوط. باستخدام تغطيات المصرف الخندقي، يتم تقليل خطر الانزلاق، مما يجعل المنطقة أكثر أمانًا للجميع.

trench drain covers

การติดตั้งเหล็กแผ่นกรองก็เป็นเรื่องง่าย และสามารถติดตั้งได้ทั้งในรูปแบบถาวรหรือชั่วคราว ขึ้นอยู่กับความต้องการและสภาพแวดล้อมของพื้นที่นั้น ๆ นอกจากนั้น การบำรุงรักษาก็ไม่ยุ่งยาก เพียงแค่ทำความสะอาดเพื่อขจัดฝุ่นละอองและเศษวัสดุที่อาจตกค้างอยู่

2. Low Maintenance One of the standout features of hot dip galvanized steel grating is its minimal maintenance requirements. Unlike uncoated steel, which may require frequent painting or replacement, galvanized grating can withstand years of exposure with little to no upkeep.

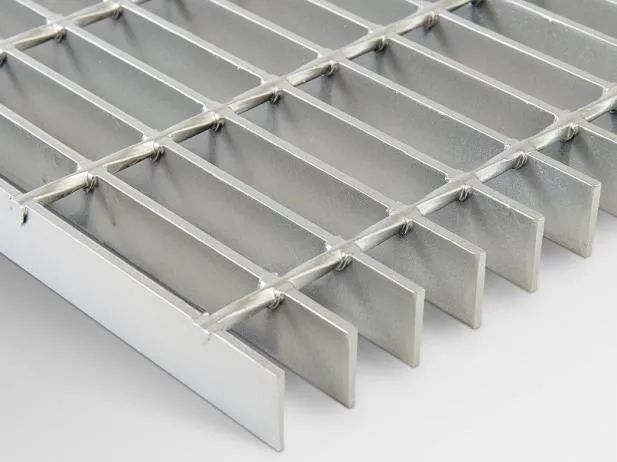

hot dip galvanized steel grating

Ein weiterer Aspekt ist die einfache Wartung von Metallrippen. Im Vergleich zu Holz, das regelmäßig behandelt und inspiziert werden muss, benötigen Metallstufen nur eine gelegentliche Reinigung. Sie sind beständig gegen Verrottung und Schädlinge, die häufig Holzprodukte angreifen. Dies trägt dazu bei, die langfristigen Kosten für Instandhaltung und Austausch zu minimieren.

The first step in finding reputable suppliers of shale shaker screens is to identify potential sources. This can be achieved through a variety of means, including industry directories, online searches, and recommendations from industry peers.

When selecting trench drain covers, it’s important to consider several factors. First, assess the size of your trench drain to ensure a proper fit. Next, think about the material that will best suit your environment; for example, stainless steel is ideal for a modern pool, while plastic might be better suited for a beach-themed setting. Additionally, think about the level of foot traffic around the pool area—more durable options may be necessary in high-traffic zones.

ステンレス製チャンネルドレインについて

La rete espansa composta da lamine metalliche o in plastica che, tramite un processo di stampaggio, vengono perforate e allargate per creare una griglia con aperture geometrica. Questa struttura consente non solo unottima traspirabilit, ma anche una buona adesione, riducendo al minimo il rischio di scivolamento in condizioni di bagnato. La sicurezza , dunque, uno dei principali motivi per cui molte amministrazioni comunali e progettisti scelgono di utilizzare questo materiale per i camminamenti.

expanded mesh walkway

निष्कर्ष

Кроме того, пластиковые лотковые крышки обеспечивают безопасное передвижение пешеходов и транспортных средств. Они могут быть выполнены с антискользящей поверхностью, что снижает риск падений и травм. Также пластиковые крышки могут быть различных цветов и форм, что позволяет легко интегрировать их в существующий ландшафт и дизайн городской инфраструктуры.

Durability is another key benefit of steel bar grating stair treads. Steel is known for its strength and resilience, making it capable of withstanding heavy loads and harsh environmental conditions. Unlike traditional materials such as wood or plastic, which may warp, rot, or deteriorate over time, steel retains its structural integrity. This longevity not only reduces maintenance costs but also contributes to the overall sustainability of the building project by minimizing the need for replacements.

steel bar grating stair treads

The thickness of steel grating, typically measured in millimeters or inches, plays a critical role in its load-bearing capacity and overall durability. Thicker grating can support more weight and withstand more significant impacts, making it vital in settings where heavy equipment and foot traffic occur. For example, a thicker grating is often used in loading docks or industrial warehouses, where heavy machinery operates regularly.

When discussing galvanized grating sizes, several key dimensions must be considered the width, length, thickness, and spacing between the bars. Standard sizes often vary depending on the manufacturer, but common bar heights range from 1 to 3 inches, and widths can vary from 2 to 6 inches. Thickness generally varies from 1/4 inch to 3/8 inch, depending on the load requirements.

Cost is always a consideration for businesses when sourcing materials. While it’s important to find a supplier that offers competitive pricing, it’s equally vital to consider the overall value provided. Cheaper options may compromise quality, leading to increased maintenance costs or safety hazards over time. A reputable supplier balances cost and quality, providing products that deliver durability and longevity, ultimately resulting in cost savings for their clients.

Manufacturing Process

3. الصيانة المنخفضة يحتاج السياج المجلفن إلى صيانة قليلة نسبيًا. خلافاً للأنواع الأخرى التي تتطلب إعادة الطلاء بشكل مستمر، يمكن الاعتماد على السياج المجلفن لفترة طويلة بدون الحاجة لصيانة دورية.

Strength.

Moreover, the manufacturing process also plays a critical role in determining the price per square meter. For example, welded steel grating is typically stronger and more durable than pressed or molded alternatives but may come at a higher price point. Additionally, the reputation and location of the manufacturer can influence pricing as well; local suppliers might offer competitive rates to attract nearby customers, while international manufacturers may impose higher shipping fees.