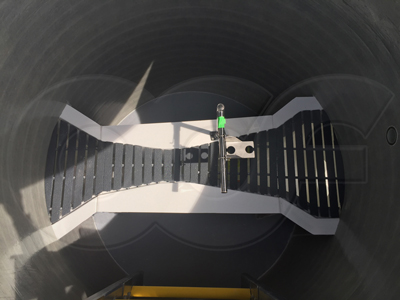

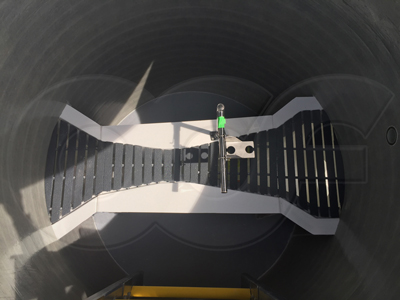

Hengshui Jrain Frp fiberglass products for steel smelting plant

M

The design of high-pressure oil seals is also critical to their performance. The seals must be able to maintain a tight fit between the moving parts, while also allowing for some flexibility to accommodate minor variations in the shaft or housing. This balance between rigidity and flexibility is essential for ensuring a reliable seal under high pressure conditions.

For bisphenol-cured VDF/HFP/TFE polymers, calcium hydroxide level should be low and magnesium oxide level should be high to promote adhesion to metal inserts. Thermal black or mineral fillers generally give good adhesion.3 For most adhesive systems, it is necessary to limit postcure temperatures to about 200°C (392°F).3

This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance

This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance This is particularly beneficial for vehicles operating in urban environments where frequent stop-and-go driving can strain engine performance oil seal turbo.

oil seal turbo. 1 inch rubber gasket. In certain types of electrical conduits and junction boxes, these gaskets are used to create a barrier against moisture and dust, protecting sensitive electrical components from environmental damage. Here, the non-conductive nature of rubber adds an extra layer of safety by preventing current leakage.

1 inch rubber gasket. In certain types of electrical conduits and junction boxes, these gaskets are used to create a barrier against moisture and dust, protecting sensitive electrical components from environmental damage. Here, the non-conductive nature of rubber adds an extra layer of safety by preventing current leakage.The primary function of an oil seal is to create a barrier between the rotating or moving parts of a machine and prevent oil or other fluids from leaking out. This helps to ensure that the machinery operates smoothly and efficiently without any loss of lubrication or contamination of the surrounding environment. In addition to preventing leakage, oil seals also help to retain lubricant within the system, extending the life of the equipment.

Rubber type

Our rubber seals are used in the following industries:

These cassette seals are widely used in wheel-end applications, such as the axles of agricultural machinery or off-road trucks.