...

2025-08-15 22:02

1431

Once the lay-up process is complete, the entire structure is cured under controlled conditions. Curing can be done at room temperature over several hours or accelerated through the application of heat. This step is crucial as it hardens the resin, transforming the flexible fiberglass into a rigid, durable tank capable of withstanding significant pressure and environmental stresses.

...

2025-08-15 21:46

294

One of the key features of a jack hammer drilling rod is its versatility

...

2025-08-15 21:43

797

Fibergrate® Molded Gratings

...

2025-08-15 21:33

1453

One of the key benefits of PP FRP tanks is their resistance to corrosion. Unlike metal tanks, which can rust and degrade over time when exposed to corrosive chemicals, PP FRP tanks are highly resistant to corrosion and can withstand a wide range of chemical environments.

...

2025-08-15 21:30

1018

At the begining of 2023, our company completed one FRP DN6m thickener tank, as a part of Thickener System, for our USA customer.

...

2025-08-15 21:22

133

Crafted from a composite material that combines glass fiber reinforcement with a resin bind, these tanks boast impressive resistance to corrosion and high mechanical strength. This blend ensures that the tank can maintain its structural integrity under duress, whether it's exposed to harsh acids or alkalis. Furthermore, the non-conductive properties of fiberglass make these tanks an excellent choice for handling electrolytic processes, where electrical interference could compromise the reaction's purity.

...

2025-08-15 21:12

169

...

2025-08-15 20:59

750

It is most commonly used for commercial floors or walkways, and bridges. But it can also be used for ramps, wash bays, platforms, and jetties.

...

2025-08-15 20:52

1898

Refractory products are typically made from materials such as fire clay, high alumina, or silica, which have high melting points and are able to withstand the extreme temperatures experienced in steel smelting plants. These products play a crucial role in maintaining the integrity of the furnace and preventing damage from the high temperatures and corrosive nature of molten metal.

...

2025-08-15 20:19

877

we carry a wide range of FRP products and systems designed to give you maximum choice. In the case of our reinforced grating, we offer two major product lines: molded grating and pultruded grating. Each manufacturing method has its own advantages and results in products with their own mix of performance and durability advantages. If you’re hesitating between molded versus pultruded grating, our experienced team can help you make that decision by highlighting the benefits of each.

Once the lay-up process is complete, the entire structure is cured under controlled conditions. Curing can be done at room temperature over several hours or accelerated through the application of heat. This step is crucial as it hardens the resin, transforming the flexible fiberglass into a rigid, durable tank capable of withstanding significant pressure and environmental stresses.

One of the key features of a jack hammer drilling rod is its versatility

Fibergrate® Molded Gratings

One of the key benefits of PP FRP tanks is their resistance to corrosion. Unlike metal tanks, which can rust and degrade over time when exposed to corrosive chemicals, PP FRP tanks are highly resistant to corrosion and can withstand a wide range of chemical environments.

At the begining of 2023, our company completed one FRP DN6m thickener tank, as a part of Thickener System, for our USA customer.

Crafted from a composite material that combines glass fiber reinforcement with a resin bind, these tanks boast impressive resistance to corrosion and high mechanical strength. This blend ensures that the tank can maintain its structural integrity under duress, whether it's exposed to harsh acids or alkalis. Furthermore, the non-conductive properties of fiberglass make these tanks an excellent choice for handling electrolytic processes, where electrical interference could compromise the reaction's purity.

...

2025-08-15 20:59

750

It is most commonly used for commercial floors or walkways, and bridges. But it can also be used for ramps, wash bays, platforms, and jetties.

...

2025-08-15 20:52

1898

Refractory products are typically made from materials such as fire clay, high alumina, or silica, which have high melting points and are able to withstand the extreme temperatures experienced in steel smelting plants. These products play a crucial role in maintaining the integrity of the furnace and preventing damage from the high temperatures and corrosive nature of molten metal.

...

2025-08-15 20:19

877

It is most commonly used for commercial floors or walkways, and bridges. But it can also be used for ramps, wash bays, platforms, and jetties.

Refractory products are typically made from materials such as fire clay, high alumina, or silica, which have high melting points and are able to withstand the extreme temperatures experienced in steel smelting plants. These products play a crucial role in maintaining the integrity of the furnace and preventing damage from the high temperatures and corrosive nature of molten metal.

we carry a wide range of FRP products and systems designed to give you maximum choice. In the case of our reinforced grating, we offer two major product lines: molded grating and pultruded grating. Each manufacturing method has its own advantages and results in products with their own mix of performance and durability advantages. If you’re hesitating between molded versus pultruded grating, our experienced team can help you make that decision by highlighting the benefits of each.

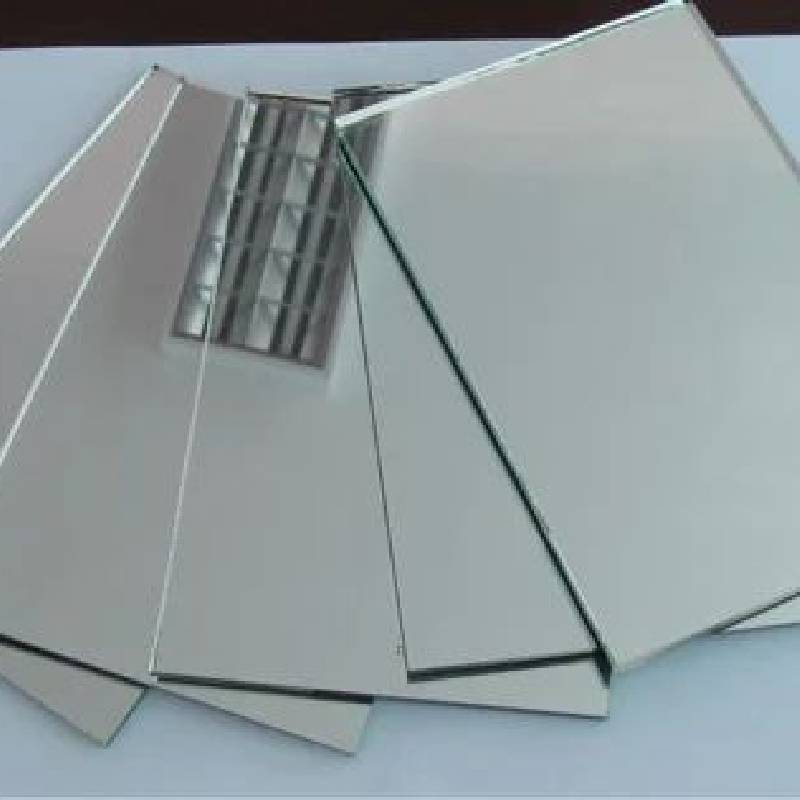

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber

Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber Once the glass has reached the desired temperature, it is removed from the furnace and placed in a cooling chamber