In biology, the spiral rod takes on a more profound role

Standard 3760/3761

Lip pumped volume

(the volume of oil, etc., pushed back at the lip contact area per unit of time)- However, it's worth noting that despite their many strengths, PTFE oil seals have their limitations. They may not be as suitable for high-speed applications due to their relatively low tensile strength and creep resistance. Nonetheless, these limitations are often countered by incorporating additional materials or design modifications.

- Sign in to download full-size image

Without spring - Square rubber gaskets, a seemingly insignificant component, play an essential role in a myriad of industrial applications. These compact, square-shaped seals are designed to fill the space between two joining surfaces, ensuring airtight or watertight seals that prevent leakage and maintain structural integrity. Their importance is often underestimated, but their functionality is vital for numerous industries, from plumbing and automotive to aerospace and construction.

- Despite the rise of electric vehicles, spark plug motors continue to hold a significant position in the global transportation sector. Their widespread use and continued development reflect their enduring importance in our daily lives. As technology advances, we can expect further improvements in spark plug design, enhancing the efficiency and sustainability of these motors.

- Trailer Hub Oil Seal: Trailer hub oil seals are designed to maintain the integrity of the wheel hub assembly on trailers and towed vehicles, preventing the leakage of lubricating oil and the ingress of contaminants. These seals are essential for ensuring the proper functioning and longevity of the wheel bearings and other internal components in trailer applications.

Rubber covered

- In conclusion, the unassuming rubber gasket plays a silent but significant role in countless aspects of modern life. Whether securing a peaceful night's sleep with a quiet HVAC system or ensuring the reliability of industrial machinery, these versatile seals protect against leaks and environmental threats. As we continue to advance technologically, the rubber gasket remains a testament to simplicity and efficiency, proving that sometimes the most effective solutions are those that quietly get the job done behind the scenes.

- Regularly inspecting and replacing the front valve cover gasket as part of routine maintenance can help prevent costly repairs and ensure the longevity of your engine. If you are unsure how to replace the gasket yourself, it is best to consult a professional mechanic who can perform the task correctly and efficiently.

How are they used?

They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell

They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell They also feature a good electrode gap, which determines the distance between the center electrode and the spark plug's outer shell truck spark plugs. A smaller gap results in a higher voltage and thus a more effective spark, while a larger gap provides a longer life to the spark plug.

truck spark plugs. A smaller gap results in a higher voltage and thus a more effective spark, while a larger gap provides a longer life to the spark plug.In addition to providing a reliable seal, the 40mm rubber gasket also helps to dampen vibrations and reduce noise, improving the overall performance and longevity of the equipment. Its durable construction ensures long-term reliability and minimizes the need for frequent maintenance or replacement.

In addition to its excellent temperature resistance, it is also resistant to ozone, light, and weather conditions. Silicone can be typically found in the food and medical industry as well as in hydraulics and pneumatics. It is often the preferred material for o-rings, moulded parts and flat seals but is also commonly used for electric insulators due to the material’s translucency and flexibility.

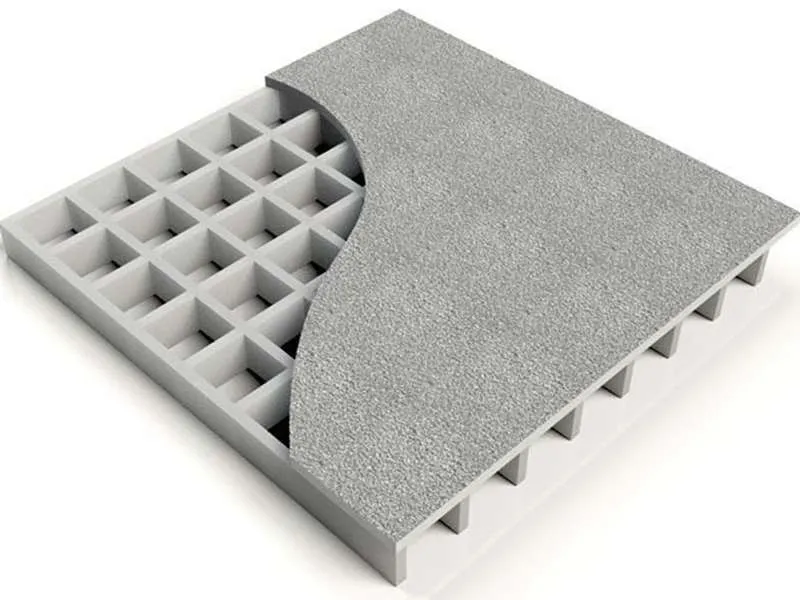

As can be seen from the seal cross-section shown in Fig. 14.2, shaft seals are complex shapes that require advanced mold design and molding techniques (see Section 7.3 for discussion of fluoroelastomer molding). For some time, most shaft seals were made in the United States by compression molding. Injection molding of shaft seals is prevalent in Europe, and is being used increasingly in the United States. An advantage of compression molding is that preforms (usually rings cut from extruded tubing) are used that closely approximate the amount of stock required for the final parts, so compound waste is minimized. For injection molding, the amount of cured stock in the central sprue and runner (actually a thin sheet leading to the seal lip) is often large compared to the stock required for the final part, so the waste of high-cost fluoroelastomer may be high. Such waste is reduced in modern injection molding designs.

Rotary Wheel Of Auto Parts

Selecting the Right Spark Plugs for Motor Vehicles

power steering oil seal. A high-quality seal made from materials such as synthetic rubber or neoprene is more resistant to wear and tear, which means it will last longer and perform better over time. On the other hand, a low-quality seal may not be able to withstand the rigors of daily driving and may need to be replaced prematurely.

power steering oil seal. A high-quality seal made from materials such as synthetic rubber or neoprene is more resistant to wear and tear, which means it will last longer and perform better over time. On the other hand, a low-quality seal may not be able to withstand the rigors of daily driving and may need to be replaced prematurely.Shaft seals, dirt seals, grease seals, lip seals, and many other names are only a few of the many names given to oil seals. They are simple components used in rotary shaft machinery to keep oil from leaking and impurities like dust, dirt, and water out. However, an oil seal’s most crucial role is to safeguard all ball, sleeve, and roller bearing types found in rotating shafts. Additionally, the seals stop blending two fluids that shouldn’t mix, such as water and oil.