Support and safety tools are equally important

The 7 degree button bit is widely employed in mining operations, construction sites, and even in geological exploration. Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries

In addition to the materials used in their construction, vessels and tanks must also be designed with features that ensure the safety and efficiency of their operation

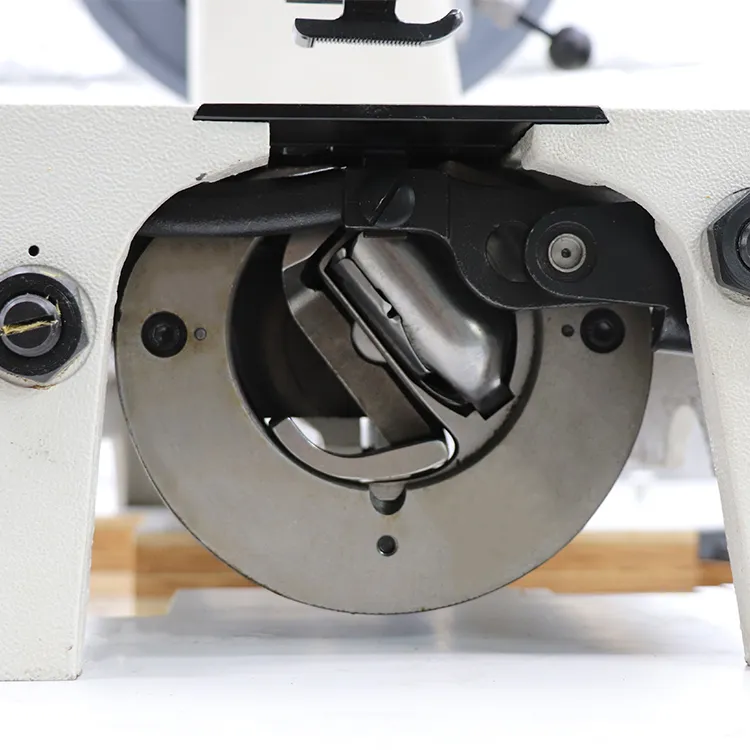

Lockstitch sewing machines are used in a multitude of applications within the textile industry. They are frequently utilized in garment construction, where they play a pivotal role in assembling pieces of fabric into finished products. Additionally, they are used for topstitching, hemming, and sewing patch pockets onto garments. Beyond clothing, lockstitch machines are also employed in upholstery, creating strong seams for furniture coverings, and in the production of accessories like bags and belts.

- Model and Features Different models come with various features, such as adjustable stitch width and length, automatic tension control, and built-in walking feet for best fabric handling. Evaluate your specific sewing needs to select the right model.

Understanding Thick Threads

The biggest difference between the two is the reason why they were built. For example, if you purchase a regular machine, you are looking for something that you will be able to use around the house. For example, you might want to mend clothes or create your own patterns. However, a heavy-duty machine was made to be used by a commercial business. This means that they will need to be able to work on a wider range of projects. Because they are designed to run for a long time, the components have been strengthened. In addition, heavy-duty machines tend to offer more advanced sewing options.

Before delving into the specifics of handheld and heavy-duty sewing machines, it's essential to assess your sewing needs. Your choice of sewing machine should align with your goals and the types of projects you intend to tackle. Consider the following questions:

Sewing through leather is a skill that can elevate your crafting, transforming ordinary projects into durable, stylish goods. The process can initially seem intimidating given leather's unique properties compared to fabric. However, once equipped with the right tools and techniques, you can master this craft and create beautiful leather items ranging from wallets to bags and even personalized home decor.

Climbing rope sewing machines are designed with features that accommodate the unique requirements of thick and resilient climbing rope materials. Unlike standard sewing machines, these specialized machines possess a robust construction that supports heavier threads and thicker fabrics. They feature high-powered motors and durable needles that can penetrate the toughest fibers without breaking.

4. Customization The versatility of stitching machines allows for customization in terms of bag size, shape, and design. This flexibility caters to the specific needs of different industries and clientele, enhancing customer satisfaction.

Industrial sewing machines are built to handle heavy-duty tasks and are typically designed for mass production in factories. These machines are faster, more powerful, and more durable than their domestic counterparts. Industrial machines can sew through multiple layers of fabric, tackle thick materials like denim and leather, and produce precise stitches quickly. Traditionally, they were reserved for professional sewing environments, but advancements in technology have made them more accessible for home use.

Finally, investing in a heavy duty sewing machine can be economically advantageous for businesses and serious hobbyists alike. The durability of these machines often translates into a longer lifespan, reducing the need for frequent repairs or replacements.

In conclusion, chain stitch sewing machines are a testament to the evolution of textile technology. Their ability to produce durable, flexible, and aesthetically pleasing seams makes them indispensable in various sectors of the sewing industry. As sustainability becomes a paramount concern, the practicality of chain stitch sewing will likely see a resurgence, affirming this machine's place in the future of fashion and textile production. Whether in a bustling factory or a home sewing setup, the chain stitch sewing machine will continue to inspire creativity and innovation for years to come.

Future Implications

In the realm of industrial sewing, the choice of machinery can significantly influence the quality and efficiency of production. Among the most advanced options are compound feed and triple feed sewing machines. This article explores the unique advantages of these machines and provides guidance on where to find a compound feed sewing machine for sale.

The Durby Zig Zag Sewing Machine has become a popular choice among sewing enthusiasts and professional tailors alike, renowned for its efficient design and versatility. In the ever-evolving world of crafting and sewing, where precision and functionality reign supreme, the Durby Zig Zag stands out as a remarkable piece of equipment. This article aims to delve into the pricing dynamics and overall value proposition of this sewing machine, helping potential buyers make informed decisions.

6. Ease of Use While heavy-duty machines are designed for strength, they should also be user-friendly. Features such as automatic needle threading, easy bobbin winding, and an intuitive interface can greatly enhance the sewing experience, making it more enjoyable for both beginners and experienced sewers.

In the world of textile production and leather crafting, the heavy-duty hand stitching machine stands out as an indispensable tool. Combining durability with a remarkable range of applications, these machines offer both hobbyists and professional manufacturers the ability to produce high-quality stitches with ease and precision.

What is Lock Sewing?

Conclusion

Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries

Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries Its ability to handle high torque and withstand extreme pressure makes it indispensable in these industries