Moreover, FRP ducts are lightweight, which significantly reduces the installation time and labor costs. Their light weight also lessens the load on building structures, making them suitable for high-rise buildings and other large-scale projects. In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety

In addition to mechanical systems, there are also natural and eco-friendly options for controlling odors

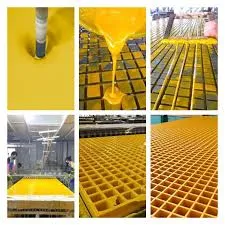

3. Material Quality The quality of the fiberglass material itself can also affect its corrosion resistance. High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion

Additionally, fiberglass stair treads are easy to clean and maintain

high pressure oil seals. O-Rings, V-Rings, and lip seals are common types, each with their own unique advantages. For instance, O-Rings are simple yet effective, while lip seals are ideal for high-speed applications due to their self-cleaning property.

high pressure oil seals. O-Rings, V-Rings, and lip seals are common types, each with their own unique advantages. For instance, O-Rings are simple yet effective, while lip seals are ideal for high-speed applications due to their self-cleaning property.Trailer hub oil seals play a critical role in maintaining the integrity of the wheel hub assembly on trailers and other towed vehicles. These seals are designed to prevent the leakage of lubricating oil and the ingress of contaminants, ensuring the proper functioning and longevity of the wheel bearings and other internal components. The trailer hub oil seal is typically positioned within the hub assembly, creating a barrier that helps retain the lubricant and protect the bearings from moisture, dirt, and debris.

Rotary Wheel Of Auto Parts

Metal O.D. wall

(with a reinforcing inner metal case)

What should you take into account when selecting an oil seal? Different types of oil seals and various types of materials are available, each designed for specific uses. It is also important to select the right size of oil seal for the best results. For this reason, selecting the right oil seal requires adequate understanding of the application in which it will be used.

Oil seals are found in a wide range of applications, in virtually every industrial sector. It is essential to select the correct oil seal so that the application in which it is used can run efficiently, free of leaks or other issues. In this blog, we explain which factors you should pay attention to when selecting the best oil seal for your application.

B) Housing-bore eccentricity

As shown in Figure 9, housing-bore eccentricity is defined as being twice the eccentricity between the housing-bore center and shaft rotation center.

Refit the distributor, ensuring that the rotor arm is exactly in line with the first mark. If not, withdraw the distributor and try again.

spark plug o ring. It is important to regularly inspect the O-ring during routine maintenance checks and replace it if necessary. A worn or damaged O-ring can lead to oil leaks, engine misfires, and other issues that can affect the performance of the vehicle.

In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety

In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety In addition, the non-conductive nature of FRP minimizes the risk of electrical hazards, enhancing workplace safety

High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion

High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion High-quality fiberglass is typically composed of pure silica sand and is treated with chemical inhibitors to enhance its resistance to corrosion