In addition to refractory products, steel smelting plants also require a range of specialized chemicals and additives to aid in the smelting process. These products can include fluxes, which are added to the molten metal to remove impurities and improve the quality of the steel, as well as inoculants, which are used to control the properties of the steel and ensure it meets the desired specifications.

...

2025-08-14 13:53

2482

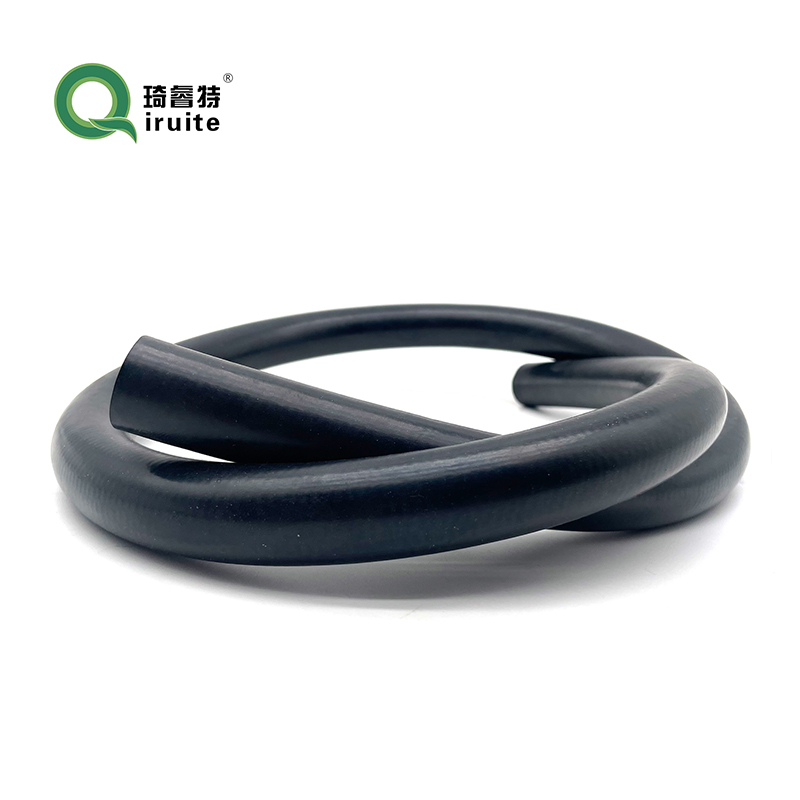

Additionally, the hose is designed to prevent refrigerant leaks, ensuring that the system operates efficiently and effectively Additionally, the hose is designed to prevent refrigerant leaks, ensuring that the system operates efficiently and effectively

Additionally, the hose is designed to prevent refrigerant leaks, ensuring that the system operates efficiently and effectively Additionally, the hose is designed to prevent refrigerant leaks, ensuring that the system operates efficiently and effectively

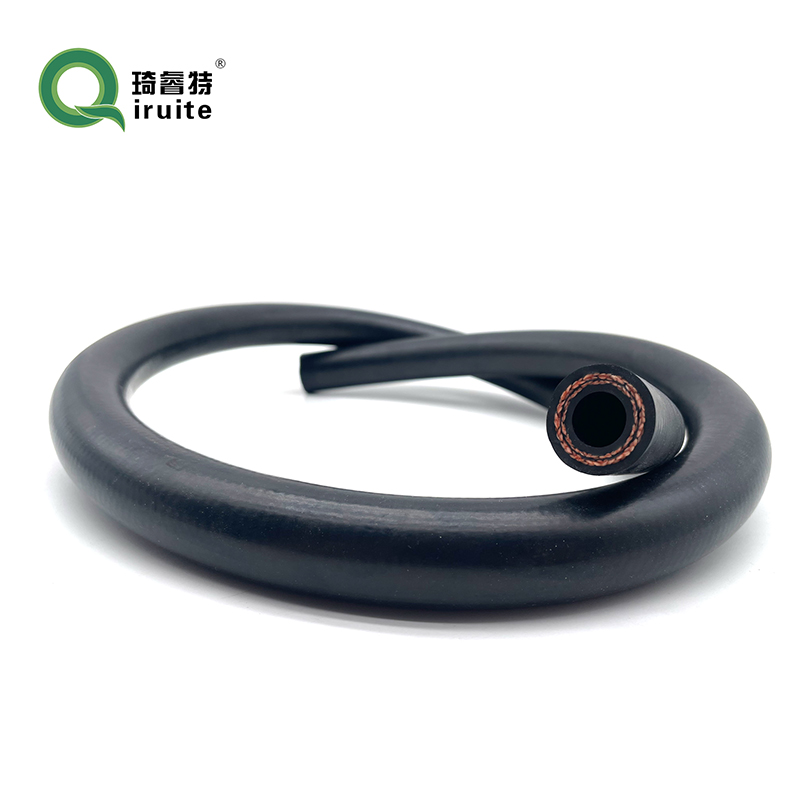

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced

Once the issue has been identified, the damaged section of the hose will need to be replaced Once the issue has been identified, the damaged section of the hose will need to be replaced A professional mechanic with experience working on Porsche 928s should perform the replacement to avoid damaging other components in the power steering system A professional mechanic with experience working on Porsche 928s should perform the replacement to avoid damaging other components in the power steering system

A professional mechanic with experience working on Porsche 928s should perform the replacement to avoid damaging other components in the power steering system A professional mechanic with experience working on Porsche 928s should perform the replacement to avoid damaging other components in the power steering system