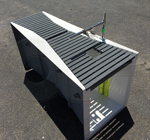

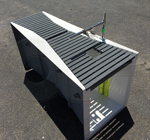

frp clarifier

The core principle of pneumatic drilling lies in the conversion of compressed air into mechanical energy. A compressor generates pressurized air, which is then channeled through a series of pipes to the drill head. The force of this compressed air rotates the drill bit, enabling it to penetrate various types of substrates, from hard rock to softer materials like soil or sediment.

An efficient clarification and filtration system is an essential part of any treatment plant. The clarifier is designed for superior removal of settleable solids in water, wastewater and industrial applications. The concave faces of the sections transport the sediment toward a sludge pit. During return movement, the wedge-shaped parts of the sections slide under the sludge blanket, providing continuous and unidirectional transport. It is easy to install and maintain.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into.

When installed in manholes or potential pedestrian traffic areas, flow monitoring flumes can be a hazard. A typical flume installation is an open trough that that an operator can inadvertently step or fall into. It can be used in a wide range of applications, from woodworking to metalworking, and can handle a variety of different materials It can be used in a wide range of applications, from woodworking to metalworking, and can handle a variety of different materials

It can be used in a wide range of applications, from woodworking to metalworking, and can handle a variety of different materials It can be used in a wide range of applications, from woodworking to metalworking, and can handle a variety of different materials