2. DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic

For larger drill bits, a taper shank may be used. Taper shanks have a gradual taper that allows them to fit securely into a drill press or lathe

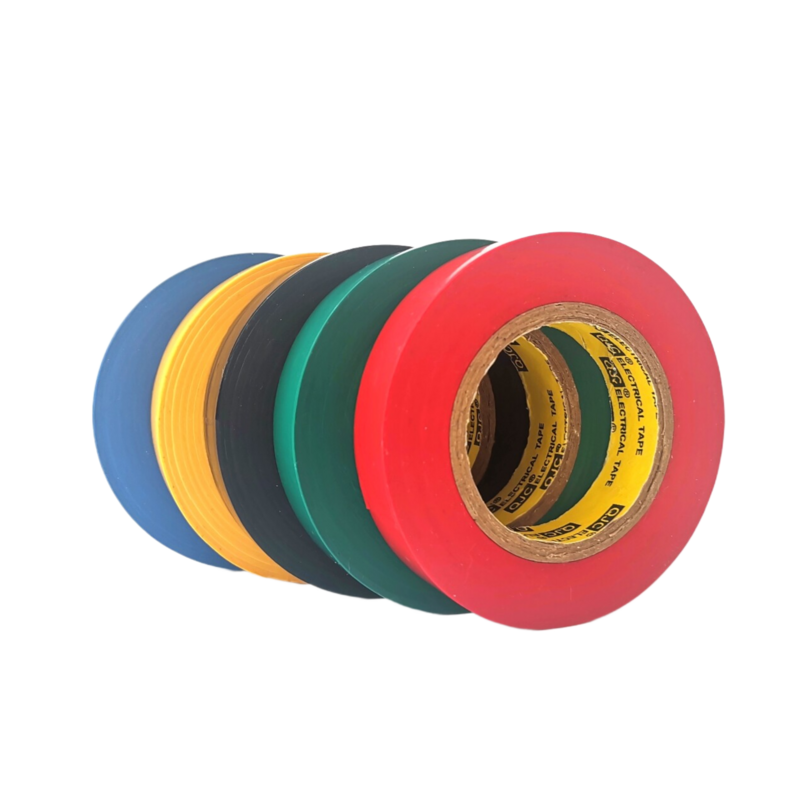

- Auto electrical cloth tape is an essential item for any mechanic or automotive enthusiast. It is a versatile and durable tape that is specifically designed for use in automotive applications. Whether you are fixing a broken wire, securing cables, or insulating electrical connections, auto electrical cloth tape is a reliable solution.

- Measuring at 50mm in width, this electrical tape is the perfect size for a wide range of tasks. Whether you need to insulate a wire, bundle cables together, or label different components, the 50mm electrical tape gets the job done efficiently.

- Seaming

In electrical applications, white PVC insulation tape is often used for insulating wires and cables. It helps to prevent electrical shorts and protects against moisture, which can lead to corrosion and system failure. Whether encasing a repair or bundling multiple wires together, this tape ensures that connections remain safe and operational.

white pvc insulation tape

2. Temperature Resistance High voltage installations often experience considerable heat. Insulation tape must be capable of operating under high temperatures while maintaining its insulating properties. Materials like PVC, silicone, and various rubber composites are commonly used for their heat-resistant qualities.

high voltage busbar insulation tape

The Versatility of Black Flex Tape

In addition to its flexibility, Flex Tape Black is also incredibly strong. Once applied, the tape forms a tight bond that is resistant to heat, cold, water, and UV rays. This means that you can rely on Flex Tape Black to provide a long-lasting and reliable seal, even in the most challenging conditions.

flex tape black 4 in x 5 ft

Water-Activated

In 1845, a surgeon named Dr. Horace Day made the first crude surgical tape by combining India rubber, pine gum, turpentine, litharge (a yellow lead oxide), and turpentine extract of cayenne pepper and applying that mixture to strips of fabric. It was the first “rubber-based” adhesive and Dr. Day used it in his practice as a surgical plaster. Larger scale manufacturing of similar medical tapes began in 1874 by Robert Wood Johnson and George Seaburg in East Orange, NJ. That company would soon become the Johnson & Johnson Company we know today. Later in 1921, Earle Dickson who bought cotton for Johnson & Johnson noticed that the surgical tape kept falling off his wife Josephine’s fingers after cutting them in the kitchen. He fixed a piece of gauze to some cloth backed tape and the first Band-Aid ® was invented. It took almost 75 years from Dr. Day’s first crude tape until the early 1920’s when the first industrial tape application appeared. The application was electrical tape (although the adhesive was more of a cohesive film than the electrical tape we know today) to prevent wires from shorting. The second major industrial tape application was a result of the rise of the American automobile in the 1920’s. Two-toned automobiles were becoming popular and automakers needed a way to produce clean, sharp paint lines while using the new automatic paint spray gun. They started using the surgical tape that was available but the paint wicked through the cloth backing and caused defective paint jobs. Richard Drew, an engineer at Minnesota Mining and Manufacturing (3M) happened to be at a local body shop testing their WetorDry® brand sandpaper in 1925 and he saw the workers struggling to get clean paint lines. He went back to his lab and created a 2-inch wide crimp backed paper tape that became the first “masking tape” for painting. Jumping ahead to 1942 and World War II, Johnson & Johnson developed duct tape to seal canisters and repair equipment for the military. The tape was a basically a polyethylene coated cloth tape with good “quick stick” properties that made it easy to use in the field for emergency repairs. The world never looked back and duct tape can be found in almost any home or toolbox.

In swimming pools and for irrigation systems

This type of tape is made from a special rubber compound that adheres to itself when wrapped around an object, creating a strong and durable bond. It is commonly used for sealing and repairing leaks in pipes and hoses, as well as for insulating electrical connections.

Moreover, the use of flame retardant tapes is not only influenced by safety concerns but also by regulatory compliance. Many countries have enacted stringent regulations governing the flammability of materials used in various applications. Using flame retardant tapes ensures adherence to these standards, thereby avoiding penalties and ensuring the safety of products in the market. Manufacturers that incorporate these tapes into their processes can also advertise their commitment to safety, potentially enhancing their reputation and appeal to customers.

Polyethylene Rubber Tape has several important characteristics:

Applications of Fire-Resistant Electrical Tape

electrical tape fire resistant

Performance advantages of silicone rubber self-adhesive tape: what are the advantages of silicone rubber self-adhesive tape

DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic

DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic DDoS protection By filtering and blocking malicious traffic, FRP scrubber can effectively mitigate DDoS attacks, protecting web applications from being overwhelmed by excessive traffic