Hengshui Jrain Frp grp winding machine

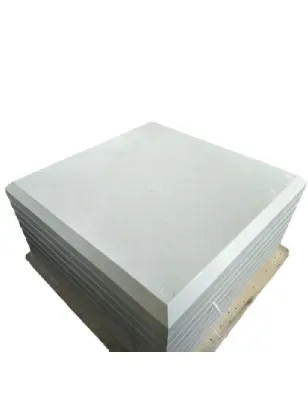

1. Molded

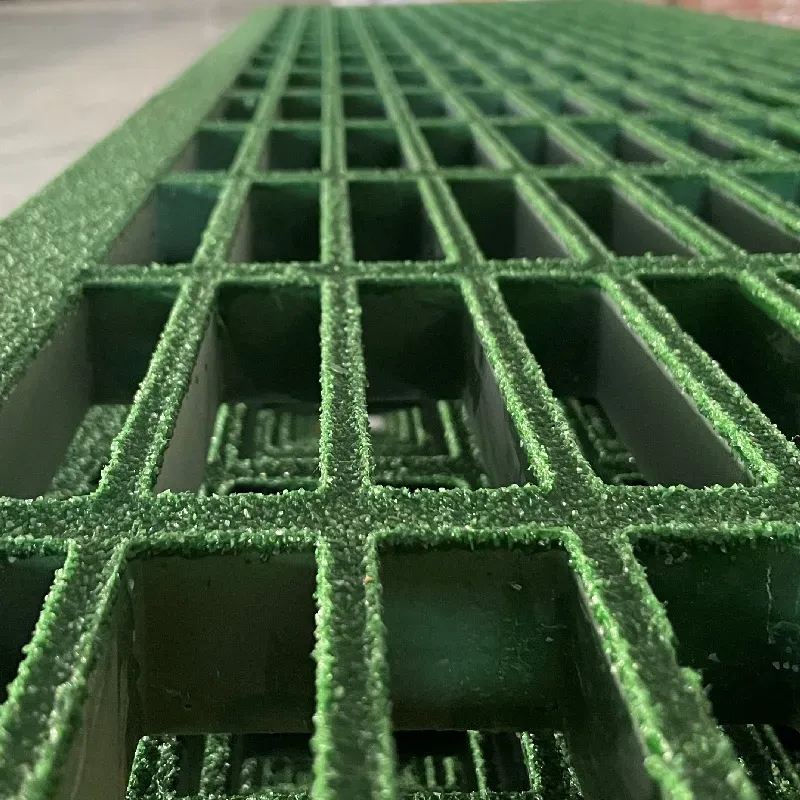

2. Pultruded

2. Pultruded

1. Molded

2. Pultruded

These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole

These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole These bits are designed to create clean and precise boreholes, reducing the need for additional reaming or cleaning of the hole retrac bit. This saves time and money during the drilling process, making retrac bits a cost-effective option for many drilling operations.

retrac bit. This saves time and money during the drilling process, making retrac bits a cost-effective option for many drilling operations.3. Ease of Installation and Adjustment Floor grating clamps facilitate a quick and easy installation process. They enable workers to efficiently install and adjust grating panels according to the specific needs of the workspace. This adaptability is particularly valuable in industries where layouts may frequently change, allowing for efficient reconfiguration of workspaces without extensive downtime.

2. Safety Features The grid design allows for good traction underfoot, reducing the risk of slips and falls. Additionally, the open slots can help prevent the accumulation of water and debris, further enhancing workplace safety.

Applications of Pultruded FRP Grating

3. Size and Capacity The dimensions and capacity of the 1054 FRP vessel are vital considerations. Larger vessels require more materials and labor, thereby increasing the price. Custom designs, tailored for specific applications, also add to the cost.

Aesthetic Appeal

The Advantages of Fibreglass Reinforced Plastic Grating

Understanding 38mm GRP Grating A Comprehensive Overview

The Growth of FRP Grating Manufacturers

2. Installation Proper installation is vital to maximize the benefits of FRP tanks. It’s advisable to hire professionals who understand the specific requirements of FRP materials.

5. Waste Management In the waste management sector, HDG pressed steel tanks are frequently used for storing industrial waste and effluent. Their resistance to various chemicals helps prevent leaks and environmental contamination.

A sand filter is a type of filtration system that uses layers of sand to trap and remove particles from water. Traditionally, these filters were constructed using materials like concrete or metal. However, the introduction of FRP as a construction material has revolutionized the design and performance of sand filters. FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass. This combination provides numerous advantages, including enhanced strength, lower weight, and superior corrosion resistance.

Furthermore, sectional tanks offer significant cost savings. Since they are often lighter than traditional tanks and can be shipped in sections, the overall transportation costs are reduced. On-site assembly minimizes the labor costs typically associated with constructing larger tanks.

The shift towards fiberglass reinforcement bars symbolizes the construction industry's broader move towards innovation and sustainability. With their remarkable characteristics and numerous advantages, GFRP bars are becoming a vital component in modern engineering designs. As technology advances and the construction landscape evolves, it is likely that the use of fiberglass reinforcement bars will continue to rise, contributing to stronger, safer, and more durable structures for future generations.

The Role of FRP Pressure Tanks in Modern Engineering

How Does an RO Water System Work?

Cost-Effective Solution

1. Corrosion Resistance One of the most significant advantages of FRP gratings is their inherent resistance to corrosion. Unlike traditional materials like steel or aluminum, FRP does not rust or corrode when exposed to harsh chemicals or marine environments. This feature significantly extends the lifespan of the walkways, reducing maintenance costs and downtime.

Similarly, in the oil and gas industry, FRP grating is crucial in offshore platforms and refineries. The material’s ability to resist harsh and fluctuating environments ensures longevity and reduces the need for frequent replacements, ultimately leading to lower operational costs.

The aesthetics and versatility of FRP mesh grating also make it an appealing option for architects and designers. Available in various colors, patterns, and sizes, FRP grating can be customized to blend seamlessly into the surrounding environment or to fulfill specific design visions. This flexibility allows for the creation of visually appealing structures without sacrificing functionality. Whether it’s used in parks, walkways, or entertainment venues, FRP grating can enhance the appearance of a space while providing necessary load-bearing capabilities.

Step 3 Progress

Sustainability is a growing concern for many industries and individuals. Stainless steel is 100% recyclable, which makes stainless steel rectangular water tanks an environmentally friendly choice. When their life cycle is complete, they can be repurposed without resulting in waste. Furthermore, the use of durable, long-lasting materials reduces the need for frequent replacements, aligning with eco-conscious practices.

4. Installation Costs

One of the key advantages of fiber water tanks is their lightweight nature, making them easier to transport and install. The flexibility in design allows for various sizes and shapes, catering to a wide range of applications—from residential use to agricultural storage needs. Furthermore, fiber water tanks are less prone to algae growth and other biological contaminants, ensuring cleaner water storage.

Water hardness is a common issue faced by many households and businesses, caused primarily by high levels of calcium and magnesium salts present in the water supply. Such hard water can lead to a host of problems, including scale buildup in pipes and appliances, decreased soap efficiency, and skin irritation. To combat these issues, water softener systems have gained popularity as an effective solution.

2. Durability Anti-slip gratings are engineered to withstand heavy foot traffic, harsh weather conditions, and the wear and tear of industrial use. Materials like fiberglass are resistant to corrosion, while steel and aluminum provide strength and longevity.

Another essential benefit of molded FRP is its resistance to corrosion and chemical exposure. Unlike metals, molded FRP does not rust or degrade when exposed to harsh environmental conditions or chemicals. This inherent property makes it particularly suitable for applications in chemical processing plants, waste treatment facilities, and marine environments, where durability is crucial.

Additionally, HDG tanks require minimal maintenance. Unlike traditional steel tanks that may need frequent painting and repairs to prevent rust, HDG tanks can maintain their structural integrity without extensive upkeep. This further reduces operational costs for businesses, allowing them to allocate resources to other critical areas.

Understanding Industrial Water Treatment

3. Versatility GRP water tanks can be customized to meet a wide range of storage requirements. They can be engineered to different sizes, shapes, and configurations, making them suitable for various applications, from domestic use to large-scale industrial projects.

6. Quantity Bulk purchases often lead to price discounts. If a project requires extensive coverage, ordering larger quantities can help in reducing the overall cost per square foot.

The filtration process in a vessel water purifier typically consists of several stages. The first stage usually involves a pre-filter that removes large particles and debris from the water. This helps to prolong the life of the main filter and improve its effectiveness. The main filter in a vessel water purifier is usually a combination of activated carbon and a porous membrane. These materials work together to remove contaminants such as bacteria, viruses, chlorine, and other harmful substances from the water.

Due to its numerous advantages, FRP sheet piling finds applications across various sectors

Advantages Over Traditional Materials

Factors Affecting Price

1. Safety The primary purpose of floor grating clamps is to secure grating panels to their supporting structures. This secures the panels in place, preventing accidental displacement that could lead to slips, trips, or falls, which are common hazards in industrial environments. A securely fastened grating system reduces the risk of injury to personnel working on or around the area.

Social media platforms and fishing forums are buzzing with discussions about the best FRP rods available on the market. In addition, instructional videos and reviews have made information more accessible, enabling novice and experienced anglers alike to make informed choices.

Durability and Longevity

5. Eco-Friendly Option As environmental awareness increases, many property owners seek sustainable materials. GRP is produced using recycled materials and can be recycled at the end of its life cycle. This eco-friendly aspect appeals to those striving for greener solutions in their construction and landscaping projects.

FRP profiles also exhibit exceptional resistance to corrosion, which is a common problem in traditional materials, especially in harsh environments such as coastal areas or industrial settings. The non-corrosive nature of FRP contributes to lower maintenance costs and extended service life, making it a cost-effective solution in the long run. Additionally, these profiles maintain their mechanical properties across a wide range of temperatures, making them suitable for diverse climatic conditions.

The Benefits of Fiberglass Water Containers

Advantages of FRP Pressure Vessel Filters

Understanding FRP Grating

In conclusion, non-slip metal grating serves a vital role in promoting safety, durability, and versatility in various applications. With their ability to reduce slip-related accidents, withstand extreme conditions, and adapt to diverse environments, these gratings are an invaluable asset across multiple industries. As safety standards continue to evolve, the demand for non-slip metal grating is likely to grow, underscoring its importance in creating safe and functional working and public spaces.

Applications of FRP Handrail Systems

Positioning your grill correctly is crucial. Always place your grill at least 10 feet away from your home and any flammable materials such as wooden decking, railings, or patio furniture. Avoid grilling under low-hanging branches or overhangs that could catch fire. A well-ventilated area reduces the risk of fire and allows for the safe dispersal of smoke and fumes.

2. Lightweight FRP tanks are considerably lighter than their metal counterparts. This feature not only reduces transportation and installation costs but also allows for more efficient handling during maintenance and operation. Furthermore, the lightweight nature of these tanks enables their installation in locations that may not support heavier structures.

Conclusion

A media filter vessel, often referred to simply as a filter vessel, is a container that houses filtering media used to remove contaminants from water. These vessels come in various shapes and sizes, depending on their application, and are constructed from durable materials like stainless steel or fiberglass to withstand various operating conditions.