sure, here's a similar short phrase drilling rock is tough but ...

...

...

...

...

...

...

...

...

...

...

- Angular contact bearings, on the other hand, are specifically designed to handle thrust loads in one direction. They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle

They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle

They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads.

ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads. - Axial cylindrical roller bearings are typically made from high-quality steel, which is heat-treated to increase its hardness and durability. The rollers and cage are also made from high-strength materials to ensure that they can withstand the stresses and strains of heavy-duty applications.

- High Speed Capability: Some cylindrical roller bearings are designed to operate at high speeds, making them suitable for applications where rotational speed is a critical factor. These bearings are engineered to minimize friction and heat generation, allowing for efficient operation at elevated speeds.

- 6005 2RS C3 Bearing A Reliable Component for Various Applications

- The 6209 Bearing A Revolution in Rotary Motion

- When evaluating the price of a 30209 bearing, it's essential to consider several factors that can affect the overall cost. These factors include the brand, quality, material, and supplier of the bearing.

- M802048 A Breakthrough in Quantum Computing

- The construction of the NJ206 bearing is meticulous, with high-quality steel providing durability and resistance to wear. The cylindrical rollers, evenly spaced within the bearing, distribute loads uniformly, minimizing stress points and increasing operational lifespan. The raceways, precisely machined, ensure minimal friction and optimal rotation, thereby reducing energy consumption and heat generation.

- The key to the 51100 bearing's superior performance lies in its innovative design and materials. The bearing features a unique geometry that distributes loads evenly across its surface, reducing friction and wear. This design also allows for increased contact area, resulting in higher load capacity and stability.

- Design and Construction

- A full complement cylindrical roller bearing, as the name suggests, is equipped with a complete set of rolling elements without any spacing or. This distinctive feature sets it apart from standard cylindrical roller bearings, which typically have fewer rollers due to the presence of these separators. The absence of allows for a higher number of rollers, thereby increasing the load-carrying capacity and providing enhanced radial support.

- * Pumps and compressors

- Another important feature of the F8 thrust bearing is its easy maintenance and low cost of ownership

- In addition to its load-carrying capacity and durability, the 6301 diameter bearing also boasts excellent rotational stability

- Overall, deep groove ball bearings are a versatile and reliable solution for a wide range of machinery applications. Their ability to accommodate heavy loads, low friction coefficient, low maintenance requirements, and environmental friendliness make them an essential component in modern machinery systems. As technology continues to advance, we can expect to see even more innovative designs and improvements in deep groove ball bearings, further enhancing their performance and reliability.

- In the realm of mechanical engineering, bearings play a pivotal role in ensuring smooth and efficient operation of machinery. One such bearing that has gained significant recognition is the Bearing 32006X. This article delves into the intricacies of this particular bearing, exploring its design, functionality, and applications.

- In general, larger bearings have higher load capacity due to their increased surface area and ability to withstand greater forces. Deep groove bearings are typically made from high-quality steel or chrome steel, which provides excellent strength and durability. Proper lubrication is also critical to ensuring optimal performance and longevity of deep groove bearings.

- Understanding 638 Bearing Dimensions A Comprehensive Overview

- The 6212 bearing is an open type, single-row, deep groove ball bearing. It has an inner diameter of 60mm, an outer diameter of 110mm, and a width of 22mm. This size makes it suitable for applications that require high speed and precision.

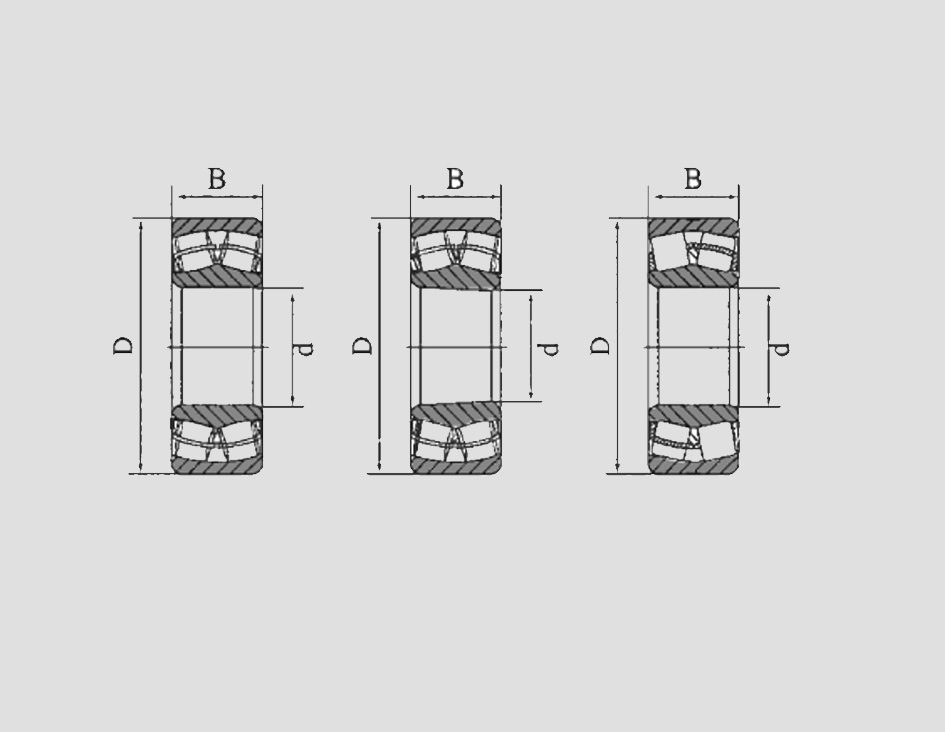

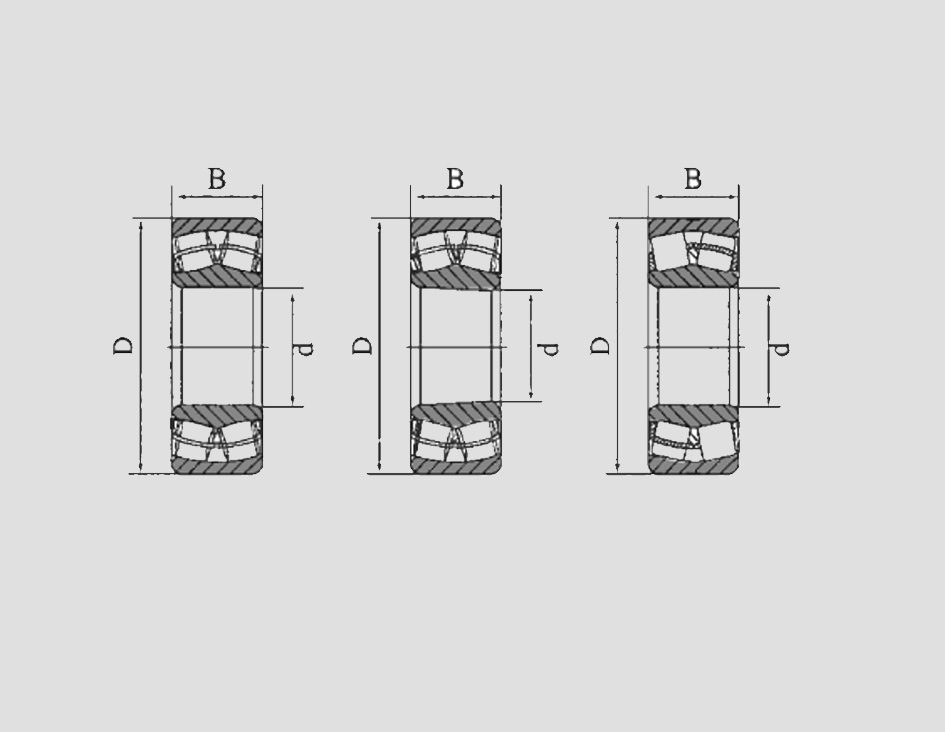

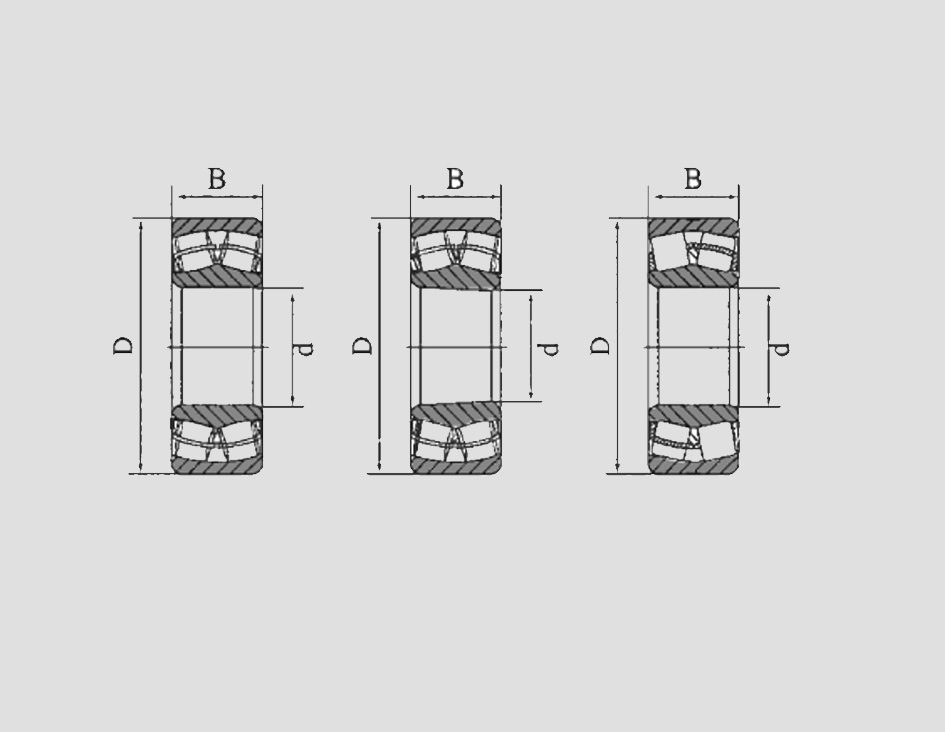

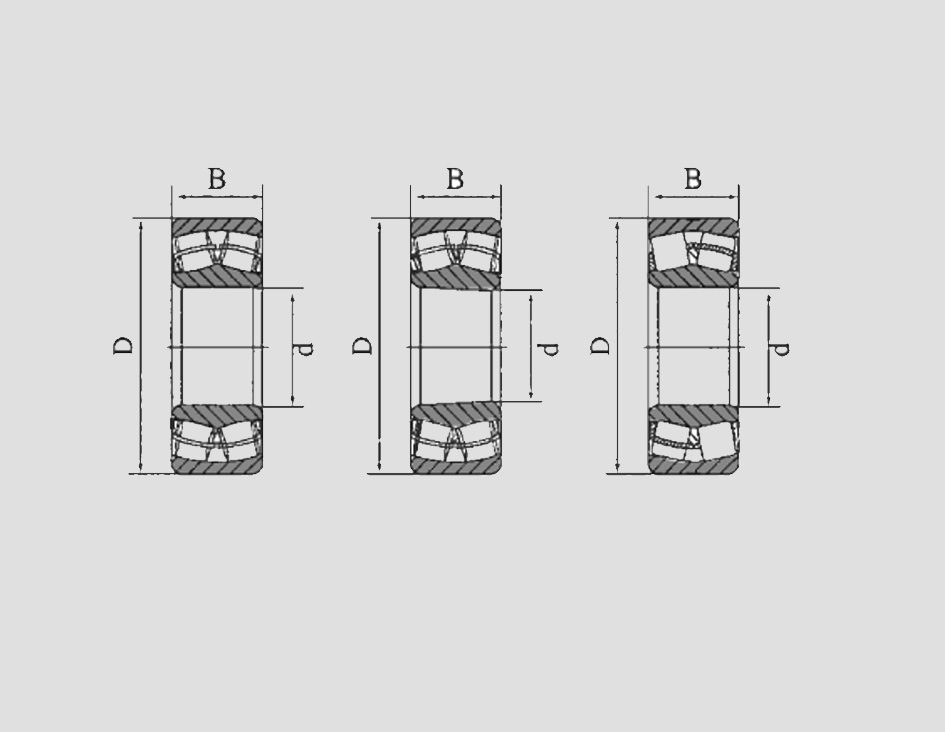

- One of the key factors to consider when selecting a spherical roller bearing is the load capacity. Spherical roller bearings are designed to accommodate both radial and axial loads, making them versatile for a wide range of applications. The dynamic load rating of a bearing indicates the maximum load it can handle while rotating at a constant speed, while the static load rating represents the maximum load it can withstand without causing permanent deformation.

- Another important feature of these bearings is their self-aligning capability

- In conclusion, the 4T L44649 bearing is an essential component in many different applications. Its versatility, reliability, and ease of maintenance make it a popular choice for industries around the world. Whether you are looking to improve the performance of your machinery or simply need a cost-effective solution, the 4T L44649 bearing is an excellent option to consider.

- 5. Construction Cylindrical roller bearings are used in excavators, pile drivers, and cranes to support heavy loads.

- 627ZZ bearings are a reliable and cost-effective solution for a wide range of rotating machinery applications. By understanding their key features and maintenance requirements, users can ensure that these bearings perform at their best and provide long-term value.

- Maintenance and selection of deep groove ball thrust bearings are critical aspects to consider. Proper lubrication is essential to minimize wear and tear and prolong the bearing's life. Furthermore, choosing the right bearing size and type, considering factors such as load capacity, speed, and operating environment, is crucial for optimal performance.

- In conclusion, bearing NU 316 plays a vital role in enhancing machinery performance by providing high load capacity, durability, temperature resistance, low maintenance requirements, and rotational accuracy. Its versatility and reliability make it a popular choice for a wide range of industrial applications. By selecting and properly maintaining bearing NU 316, manufacturers can ensure the long-term success and profitability of their operations.

- In conclusion, cylindrical roller bearings and spherical roller bearings are essential components in many mechanical systems. Their ability to handle heavy loads, withstand misalignment, and operate at high speeds makes them ideal for a wide range of industrial applications. By choosing the right type of bearing for a specific application, engineers can ensure reliable and efficient operation of machinery, reducing downtime and maintenance costs.

- * Industrial machinery and equipment

- Angular Contact Bearings:

- Secondly, the complexity of the design and manufacturing process contributes to the pricing. Tapered bearings require precise engineering, with each component - the cones, cups, and rollers - needing to be manufactured to exacting tolerances. This precision engineering, coupled with the need for rigorous quality control, increases the production cost, which is then reflected in the selling price.

- Conclusion

- Another benefit of single deep groove ball bearings is their versatility in terms of applications. They are commonly used in electric motors, pumps, gearboxes, and conveyor systems, among other machinery. The single row design allows for compact and lightweight construction, making them ideal for space-constrained installations. Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements

Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements

Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements single deep groove ball bearing.

single deep groove ball bearing. - 2

an 02-series single-row deep-groove ball bearing is to be selected. High Speed Capability These bearings are designed to operate at high speeds, making them ideal for use in high-speed rotating machinery such as pumps, fans, and turbines.

an 02-series single-row deep-groove ball bearing is to be selected. High Speed Capability These bearings are designed to operate at high speeds, making them ideal for use in high-speed rotating machinery such as pumps, fans, and turbines.

- The Bearing 51309 A Comprehensive Guide

- The quality of the bearing is another crucial factor to consider. High-quality bearings may have a higher price tag, but they are often more durable and have a longer lifespan. It's important to invest in a quality bearing to prevent costly repairs or replacements in the future

30209 bearing price. - Market demand is another key factor influencing bearing prices

- * Gearboxes

- * Ensure that the bearing is properly lubricated with the correct type and amount of lubricant.

- Another important feature of the 6005 2RS C3 bearing is its C3 clearance, which provides extra space between the rolling elements and the inner and outer rings. This clearance helps reduce friction and heat generation within the bearing, ensuring smoother operation and longer service life.

- Conclusion

- 2. Limited Durability Low-price bearings may not be as durable as higher-quality alternatives, leading to more frequent replacements and maintenance requirements.

- In conclusion, mastering the knowledge of bearing dimensions such as those found in a 63006 bearing is fundamental for ensuring proper functioning and longevity of machinery. By paying close attention to specifications and tolerances, engineers can make informed decisions about which bearings to use, how they should be installed, and when they may need replacement. This meticulous approach to component selection is what sets successful industrial operations apart from those plagued by frequent breakdowns and costly repairs.

- In addition to their direct impact on machinery performance, 6010 bearings also contribute to energy savings and environmental protection. By reducing friction and increasing efficiency, these bearings help to lower energy consumption and reduce greenhouse gas emissions.

- Maintenance of the 6302 Bearing

- The LM501349 Bearing A Precision Engineering Marvel

- 2. High Load Capacity These bearings are designed to handle heavy loads and are particularly suitable for applications such as gears, pumps, and wind turbines. The unique design of the tapered rollers and cage allows them to distribute loads evenly across the bearing surface, resulting in increased durability and longevity.

They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle

They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle They have one shoulder on the inner ring and another on the outer ring, positioned in such a way that they make contact with the balls at an angle ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads.

ball bearing thrust load. This unique configuration allows them to effectively manage high thrust loads while simultaneously supporting radial loads. Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements

Additionally, they are available in a range of sizes and configurations to meet specific performance requirements Additionally, they are available in a range of sizes and configurations to meet specific performance requirements single deep groove ball bearing.

single deep groove ball bearing. an 02-series single-row deep-groove ball bearing is to be selected. High Speed Capability These bearings are designed to operate at high speeds, making them ideal for use in high-speed rotating machinery such as pumps, fans, and turbines.

an 02-series single-row deep-groove ball bearing is to be selected. High Speed Capability These bearings are designed to operate at high speeds, making them ideal for use in high-speed rotating machinery such as pumps, fans, and turbines.