Their operation is straightforward as well. They are commonly used with a drill press for accuracy and stability, but can also be employed with a hand drill, albeit with less precision. The central point guides the bit while the flat edges cut away the material. However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry

The process of using a thread drill bit is relatively simple. First, the material to be drilled must be clamped securely in place. Then, the thread drill bit is inserted into a drill press or hand drill and rotated at high speed. As the bit cuts into the material, it creates a helical groove that forms the threads. Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform

- 1. Versatility Both Ponceau 4R and titanium dioxide are highly versatile ingredients that can be used in a wide range of cosmetic products.

- Lithopone is known for its excellent covering power and brightness, making it an ideal choice for use in paints, coatings, plastics, and rubber. It is also used as a filler in paper, ceramics, and inks. Due to its unique chemical properties, lithopone provides good weather resistance, durability, and lightfastness when used in various applications.

- What are the key regulatory procedures and requirements for setting up a lithopone manufacturing plant?

Loman Lithopone B311

White power, is a mixture of zinc sulfide and barium sulfate. Its whiteness, strong hiding power than zinc oxide, refractive index and opaque force than zinc oxide and lead oxide.

Applications:

Used for paint, ink, rubber, polyolefin, vinyl resin, ABS resin, polystyrense,polycarbonate, paper, cloth, leather, enamel, etc. Used as a binder in buld production.

Storage:

The product is a kind of white power which is safe, nontoxic and harmless. Keep from misture during transport and should be stored in a cool, dry condition. Avoid breathing dust when handling, and wash with soap & water in case of skin contact. For more details, please refer to the MSDS.

With the increasing demand for titanium dioxide in various industries, the search for reliable suppliers has become crucial. Among the numerous suppliers in the market, r 996 titanium dioxide suppliers have emerged as one of the leading suppliers in the industry.

In conclusion, calcium carbonate and titanium dioxide are important minerals that are used in various industries. While they are both produced by manufacturers, they have different manufacturing processes and applications. Understanding the differences between these two minerals can help industries make informed decisions about which one to use for their specific needs.

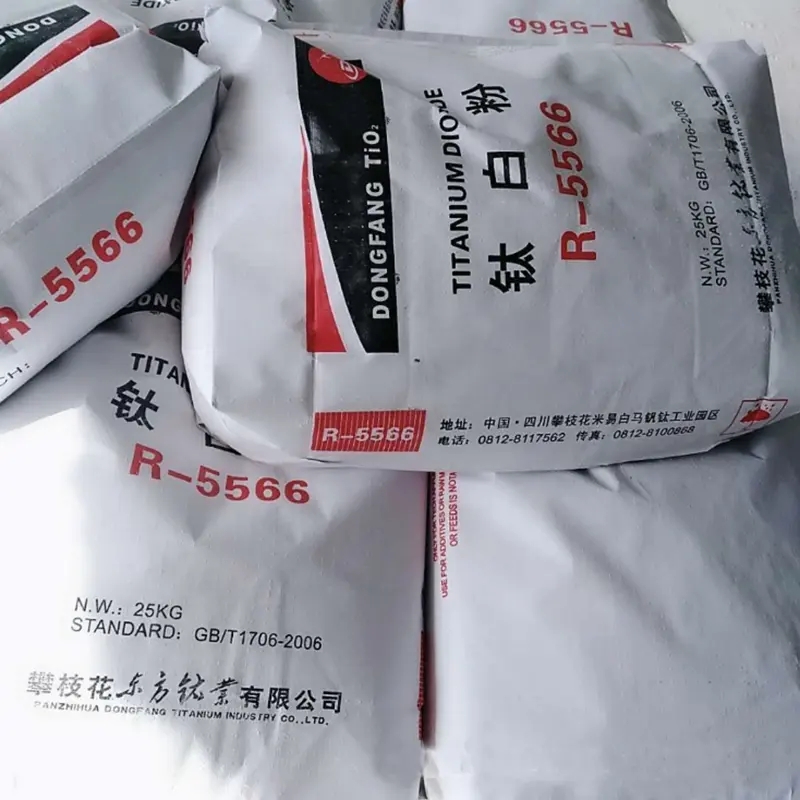

This TiO2 manufacturer mainly produces R5566, R5567, R5568, R5569 and other series products, which are used in coatings, plastics, papermaking, ink and other fields.

Atherosclerosis

Lithopone 30% is a perfect alternative to titanium dioxide in all natural and synthetic pigmented elastomers, as it is non-abrasive and extremely acid resistant.

The company operates several production facilities globally and offers a wide range of TiO2 products, including rutile, anatase, and speciality grades The company operates several production facilities globally and offers a wide range of TiO2 products, including rutile, anatase, and speciality grades

The company operates several production facilities globally and offers a wide range of TiO2 products, including rutile, anatase, and speciality grades The company operates several production facilities globally and offers a wide range of TiO2 products, including rutile, anatase, and speciality grades tio2 white manufacturers. Tronox Limited is committed to sustainability and has implemented several environmental initiatives to reduce its carbon footprint. The company also places a strong emphasis on safety and health, and has received numerous awards for its commitment to these areas.

tio2 white manufacturers. Tronox Limited is committed to sustainability and has implemented several environmental initiatives to reduce its carbon footprint. The company also places a strong emphasis on safety and health, and has received numerous awards for its commitment to these areas.Loman Lithopone B311

White power, is a mixture of zinc sulfide and barium sulfate. Its whiteness, strong hiding power than zinc oxide, refractive index and opaque force than zinc oxide and lead oxide.

Applications:

Used for paint, ink, rubber, polyolefin, vinyl resin, ABS resin, polystyrense,polycarbonate, paper, cloth, leather, enamel, etc. Used as a binder in buld production.

Storage:

The product is a kind of white power which is safe, nontoxic and harmless. Keep from misture during transport and should be stored in a cool, dry condition. Avoid breathing dust when handling, and wash with soap & water in case of skin contact. For more details, please refer to the MSDS.

Prof. Maged Younes, Chair of EFSA’s expert Panel on Food Additives and Flavourings (FAF), wrote of the decision: “Taking into account all available scientific studies and data, the Panel concluded that titanium dioxide can no longer be considered safe as a food additive. A critical element in reaching this conclusion is that we could not exclude genotoxicity concerns after consumption of titanium dioxide particles. After oral ingestion, the absorption of titanium dioxide particles is low, however they can accumulate in the body.”

Scattering Power of TiO2 and Pigment Volume Concentration

Genotoxicity refers to the ability of a chemical substance to damage DNA , the genetic material of cells. As genotoxicity may lead to carcinogenic effects, it is essential to assess the potential genotoxic effect of a substance to conclude on its safety.

cheap barium sulphate superfine factory. This is typically achieved through a combination of grinding and classification techniques. The resulting barium sulfate powder is then dried and packaged for distribution.

cheap barium sulphate superfine factory. This is typically achieved through a combination of grinding and classification techniques. The resulting barium sulfate powder is then dried and packaged for distribution. china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth.

china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth.What's the deal with titanium dioxide?

The price trendss for titanium dioxide kept on the lower side of the scale during the first half of 2023. As the paint and coatings industries reduced their offtakes, the abundant supply of the product in the market led to a fall in prices. The prices also suffered from falling energy costs and declining freight charges. Further, the rising speculations of a global recession caused manufacturers to participate actively in destocking.

While Skittles don't include white in their line-up, Dr. Johnson-Arbor theorizes that titanium dioxide is used to help contain all the other beautiful colors.

Titanium dioxide R-5566, a rutile titanium dioxide pigment treated with zirconium and aluminum inorganic surface and organic surface, has the characteristics of high whiteness, high gloss, high achromatic power, high weather resistance, and good dispersibility.

The report also provides detailed information related to the lithopone manufacturing process flow and various unit operations involved in a manufacturing plant. Furthermore, information related to mass balance and raw material requirements has also been provided in the report with a list of necessary quality assurance criteria and technical tests.

Pure PVB is non-toxic and harmless to human body. In addition, ethyl acetate or alcohol can be used as solvent, so PVB is widely used in printing ink of food containers and plastic packaging in European and American countries.

Storage safety properties

PVB can be stored for two years without affecting its quality as long as it is not in direct contact with water; PVB shall be stored in a dry and cool place and avoid direct sunlight. Heavy pressure shall be avoided during PVB storage.

Solubility

PVB is soluble in alcohol, ketone, ester and other solvents. The solubility of various solvents changes according to the functional group composition of PVB itself. Generally speaking, alcohol solvents are soluble, but methanol is more insoluble for those with high acetal groups; The higher the acetal group, the easier it is to dissolve in ketone solvents and ester solvents;

PVB is easily soluble in cellosolve solvents; PVB is only partially dissolved in aromatic solvents such as xylene and toluene; PVB is insoluble in hydrocarbon solvents.

Viscosity characteristics of PVB solution

The viscosity of PVB solution is greatly affected by the formula of solvent and the type of solvent; Generally speaking, if alcohol is used as solvent, the higher the molecular weight of alcohol, the higher the viscosity of PVB solution;

Aromatic solvents such as xylene and toluene and hydrocarbon solvents can be used as diluents to reduce the viscosity of PVB solution; The effect of PVB chemical composition on viscosity is summarized as follows: under the same solvent and the same content of each base, the higher the degree of polymerization, the higher the solution viscosity; Under the same solvent and the same degree of polymerization, the higher the acetal group or acetate group, the lower the solution viscosity.

Dissolution method of PVB

Where mixed solvents are used, the dissolution step is to first put aromatic solvents (such as xylene, toluene, etc.) or ester solvents (such as n-butyl acetate, ethyl acetate, etc.) into the mixing, slowly put PVB into the mixing, and then add alcohol solvents (such as n-butanol, ethanol, etc.) after PVB is dispersed and expanded,

At this time, the dissolution time can be shortened by heating; Using this dissolution method, the formation of lumpy PVB can be avoided (because the dissolution time will be several times after the formation of lumpy PVB), so the dissolution speed can be accelerated. Generally, the ratio of aromatic and alcohol solvents is 60 / 40 ~ 40 / 60 (weight ratio), and PVB solution with low viscosity can be prepared.

The solvent composition contains 2 ~ 3wt% water, which can improve the hydrogen bonding strength of alcohol solvents and help the solubility of PVB.

Processing properties

Although PVB resin is a thermoplastic, it has little processability before plasticizer is added. Once plasticizer is added, its processability is very easy.

The purpose of general coatings and adhesives is to change the resin characteristics by adding plasticizers to meet the application requirements, such as film softness, reducing the TG point of the resin, reducing the heat sealing temperature, maintaining low-temperature softness, etc.

Compatibility

PVB can be compatible with a variety of resins, such as phenolic resin, epoxy resin, alkyd resin and MELAMINE resin.

B-08sy, b-06sy and b-05sy with high acetal degree can be mixed with nitrocellulose in any proportion. PVB and alkyd resin are partially compatible. General PVB is compatible with low molecular weight epoxy resin, while high molecular weight epoxy resin needs PVB with high acetal degree to be compatible with each other.

Still many experts say the body of research does not support the current health concerns being expressed about titanium dioxide.

As of August 7, the use of titanium dioxide in food is banned in the European Union. Europe is taking a precautionary principle approach based on findings from the European Food Safety Authority (EFSA).

Polyvinyl butyral (PVB) is dissolved into 12 ~ 14% solution with ethanol and made into film. It is used for printing paper film of ceramic (or enamel) products. The fired ceramic (or enamel) patterns have bright color and smooth texture. The flower paper is characterized by convenient use, low cost, smaller than the original glue, greatly reducing the decal process and high color burning rate. At present, most porcelain factories in China have formed relatively formal production lines for standardized production. Therefore, the demand for PVB in the ceramic (or enamel) flower paper industry is increasing.

Application field of polyvinyl butyral -- electronic adhesive

Polyvinyl butyral contains hydroxyl, vinyl acetate and butyraldehyde, which has high bonding properties. Phenolic Resin was added into PVB ethanol solution to make adhesive, which can be used for a long time at 120 ℃. The product has strong adhesion to metal, wood, leather, glass, fiber and ceramics; FRP can be manufactured to replace non-ferrous metals such as steel, aluminum and copper; The adhesive made by adding this product and curing agent into epoxy resin is often used for bonding and assembly of electronic instrument components, bonding between metal and porous materials, emergency repair, etc. it can also be used in the field of electronic ceramics. In the development of ceramic integrated electronic circuits, this product with medium viscosity and low hydroxyl is used as ceramic powder adhesive to increase the primary strength of ceramics.

Application field of polyvinyl butyral -- copper foil adhesive

Polyvinyl butyral (PVB) and phenolic resin cooperate to produce copper foil adhesive, which is used in the production of copper clad laminate. It has good peel strength and tin welding temperature resistance, and is widely used in various fields.

Application field of polyvinyl butyral - self adhesive enamelled wire paint

Polyvinyl butyral is the main raw material of self-adhesive enamelled wire paint. After the enameled wire is wound and formed in the electrodes of motors, electrical appliances and instruments, as long as it is heated for several minutes at a certain temperature or treated with appropriate solvent, the coils can be bonded together by themselves without impregnation and drying.

However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry

However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry However, due to their size and design, they are not suitable for drilling into harder materials like metal or masonry Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform

Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform Once the desired depth and pitch of the threads have been achieved, the bit is removed and the threads are finished by tapping, which involves driving a tap into the threads to clean them up and ensure they are uniform