Moreover, the lightweight quality of FRP fittings simplifies transportation and installation. Workers can easily handle these components, reducing labor costs and improving safety compared to heavier metallic alternatives. The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency

fiberglass trough cover. Their lightweight design allows for easy handling and placement, reducing labor costs and downtime. Additionally, their resistance to chemicals and weathering means they require minimal upkeep, translating into long-term cost savings.

fiberglass trough cover. Their lightweight design allows for easy handling and placement, reducing labor costs and downtime. Additionally, their resistance to chemicals and weathering means they require minimal upkeep, translating into long-term cost savings.The Rise of Automatic Sewing Machines for Shirts

Traditionally, sewing leather was done by skilled artisans using hand-operated tools. This method, while effective, was time-consuming and required a high level of expertise. With the advent of industrial sewing machines in the 20th century, the production process underwent a significant transformation. These machines are engineered to handle the unique characteristics of leather, which is heavier and more robust than other fabrics.

The performance of a sewing machine, regardless of its build or intended use, greatly depends on its maintenance. When sewing light fabrics, even minor hiccups caused by a lack of maintenance can lead to significant issues, from uneven stitches to fabric damage.

4. Integration with Design Software Many auto cutter machines are now equipped with integrated software that allows seamless communication between design and production. This feature enables pattern adjustments to be made in real-time, ensuring that any design changes can be executed quickly and accurately.

4. Cost-Effective Compared to multi-stitch machines with extensive features, single stitch models are often more affordable. For those just starting in leather crafting or who are on a budget, this makes for a practical investment.

single stitch leather sewing machine

The textile industry has seen countless innovations over the years, but few have been as impactful as the baffle sewing machine. This remarkable piece of machinery has revolutionized the way fabrics are stitched together, bringing efficiency, precision, and versatility to the world of garment and textile production.

Applications in the Textile Industry

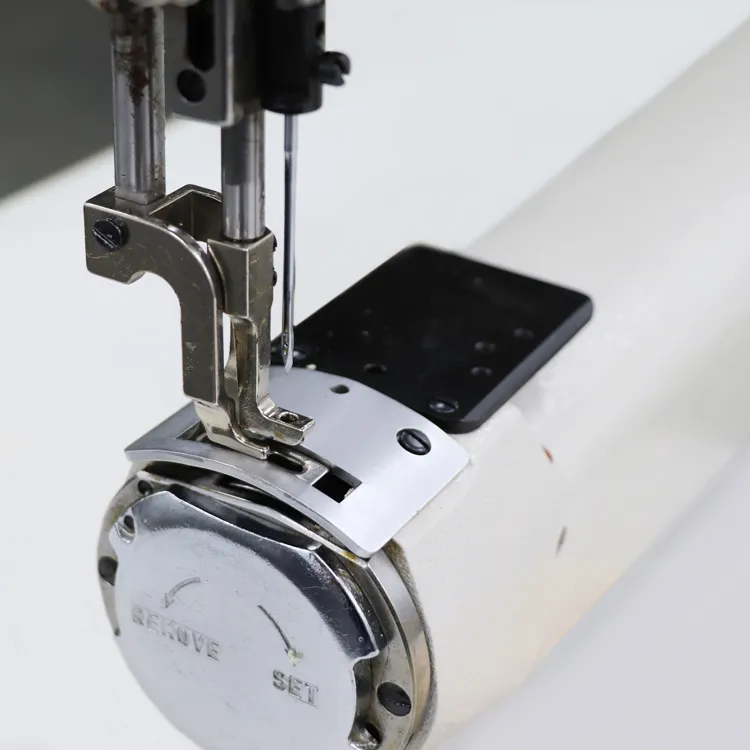

The lock stitch sewing machine operates using a dual-thread system one thread is fed from the needle, and the other from a bobbin beneath the fabric. This configuration creates a tight, secure stitch that is well-suited for a variety of fabrics and applications. The needle itself plays a crucial role in this process, acting as the point where the upper thread penetrates the fabric, forming the stitch and interlocking with the lower thread.

what is an overlock serger sewing machine. It creates a flat, flat seam that is flexible and perfect for garments that require stretch and movement. Lastly, the cover stitch is perfect for hemming garments, sewing on bindings, or even creating decorative topstitching. It creates a professional-looking finish that is commonly seen on store-bought garments.

User-Friendly Design

Portable bag closer machines are designed to close bags of various materials, including poly, paper, and woven bags. These machines are particularly useful in industries such as agriculture, food processing, and construction, where bags are essential for containing products like grains, fertilizers, and pet food. The ability to quickly seal bags at different locations helps streamline operations and reduce labor costs.

One of the key features of the Cub sewing machine is its compact size. Despite its small footprint, this machine packs a powerful punch, with a high-speed motor that can handle even the toughest fabrics. Whether you are sewing lightweight cotton or thick denim, the Cub sewing machine can handle it all with ease. Its automatic needle threader and drop-in bobbin system make threading and bobbin winding a breeze, while its adjustable stitch length and width allow you to customize your projects to your liking.

cub sewing machine for sale

4. Adjusting the Tension and Stitch Settings

sew leather with regular sewing machine

With a long arm zig zag sewing machine, sewists can experiment with different stitch styles and techniques. The machine opens up a world of possibilities—from applying bias tape to creating intricate embroidery designs. Many models come equipped with preset zig zag stitch options, allowing users to choose the right stitch for their project with just the press of a button. Moreover, advanced models often include adjustable stitch width and length, giving users complete control over the outcome of their sewing projects.

Understanding Straight Stitch and Zigzag Stitch

2. Enhanced Fabric Handling The design of the zigzag presser foot allows for better control over the fabric as it moves through the machine. This is particularly beneficial when sewing with stretchy or slippery materials.

3. Buttonhole Foot Creating buttonholes can be intimidating, but a buttonhole foot simplifies the process. This attachment guides the fabric to create uniform and accurately sized buttonholes, making it a must-have for garment sewing.

foot for sewing machine

5. Presser Foot A walking foot is essential for heavy fabrics as it ensures even feeding of the layers and helps prevent puckering.

- Thread Selection Use high-quality thread to avoid breakage and ensure smooth stitching. Different fabrics may require specific thread types; for instance, polyester threads are often recommended for added stretch.

Heavy-duty sewing and embroidery machines represent a blend of strength, efficiency, and versatility. Whether you are a seasoned professional, a hobbyist, or just starting your sewing journey, the right heavy-duty machine can elevate your work and inspire creativity. By carefully considering your project needs and the features of different machines, you can choose the perfect companion for all your sewing and embroidery endeavors. Embrace the possibilities that await with a reliable heavy-duty machine, and watch your crafts reach new heights!

hd sewing machine. From automatic thread cutting to adjustable stitch length and width, these machines provide users with the flexibility and versatility needed to create a variety of sewing projects. With built-in LED lights for improved visibility and a wide range of accessories and attachments, HD sewing machines make sewing easier and more enjoyable.

auto cut sewing machine. Users can easily adjust the settings of the machine to create different types of stitches, seams, and finishes, allowing for a greater level of creativity and versatility in their sewing projects. Whether you are a professional tailor or a hobbyist seamstress, an auto cut sewing machine can help you bring your creative vision to life.

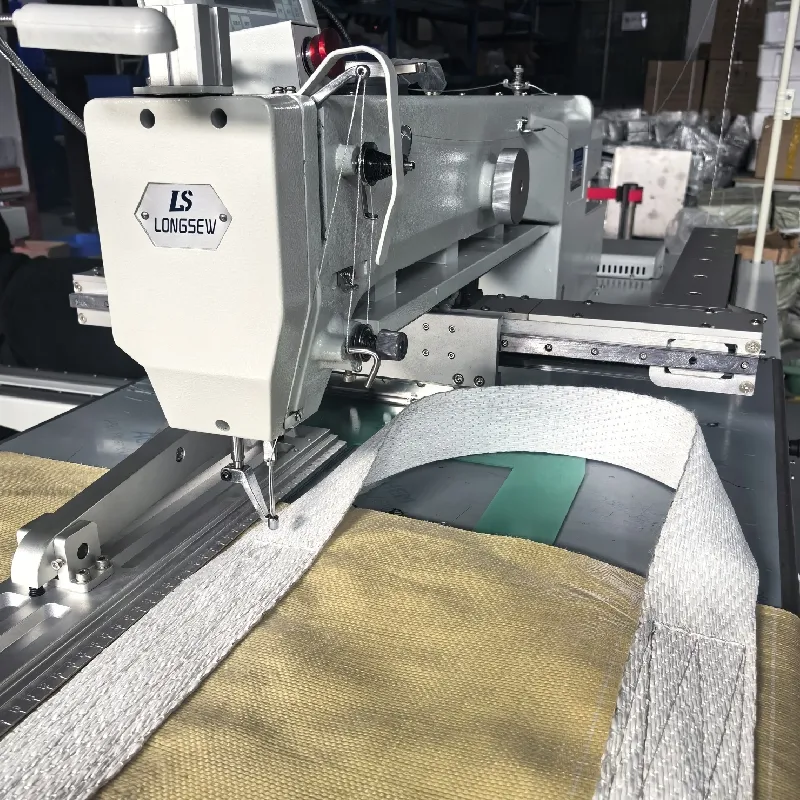

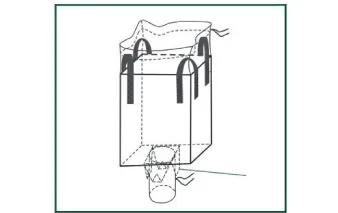

jumbo bag lock stitch machine. This is essential for ensuring the integrity of the bags during storage and transportation, especially when dealing with heavy or abrasive materials. Additionally, the machine's high stitching speed and accuracy contribute to increased productivity and reduced production costs.

The Versatile Zigzag Foot Sewing Machine A Seamstress's Best Friend

2. Strength and Durability Heavy-duty sewing machines are built to last. Their sturdy construction means they can withstand the pressures of frequent use without wearing down. This longevity makes them a worthwhile investment, especially for those who sew regularly or run a small business.

sewing heavy duty

This article will help you learn what to look for when shopping for the best heavy duty sewing machine and what features are a must.

1. Efficiency A specialized sewing table streamlines your workflow, allowing you to transition seamlessly between cutting, sewing, and assembling pieces. This efficiency can save you time and reduce frustration.

Choosing the right needle is also crucial. A larger, heavy-duty needle (usually a size 16 or 18) is recommended for piercing the dense fibers of heavy canvas. Furthermore, using a walking foot can enhance the feeding of the fabric, preventing slippage and ensuring smooth stitching. It's important to select appropriate thread; polyester or heavy-duty nylon threads are ideal choices that offer strength and durability.

sewing heavy canvas

The ease of use and time-saving capabilities of the automatic buttonhole sewing machine are invaluable, particularly for those handling large sewing projects. For small businesses and home-based seamstresses, the ability to quickly and accurately make buttonholes can significantly enhance productivity and contribute to a more efficient workflow. As a result, these machines have become increasingly popular among fashion designers and tailors looking to streamline their production processes.

Benefits of Using a Single Needle Edge Cutter Machine

Programmable pattern sewing machines are invaluable in various sectors, including fashion design, quilting, and home décor. Fashion designers can use these machines to produce intricate designs that would otherwise be time-consuming and challenging to achieve by hand. Quilters benefit from the precision and consistency that programmable machines offer, especially when creating large blocks or repetitive patterns.

2. Time-Saving Time is precious, and many crafters seek machines that can quickly and efficiently help them achieve their goals. Self-threading features can save a considerable amount of time during setup, allowing users to spend more of it on sewing and creativity.

One of the main advantages of a double needle walking foot sewing machine is its ability to handle a wide variety of fabrics effortlessly. Whether you are working with heavy materials such as denim and canvas or delicate fabrics like lace and chiffon, this machine provides the stability and control needed to achieve professional results. It is particularly favored by quilters and garment makers who require precision and durability in their sewing projects.

What is a Zig Zag Industrial Sewing Machine?

Sewing leather requires specific tools to achieve the best results

For instance, in the food industry, sealed bags help prevent contamination, prolong shelf life, and facilitate an efficient supply chain. In agriculture, the right seaming machine can secure fertilizers, seeds, and grains in a manner that protects them from environmental factors.

Chain stitch has a wide range of applications. It is particularly favored in industries where elasticity is essential, such as in sewing t-shirts and activewear. The flexibility of chain stitches allows for greater movement, making garments comfortable and durable.

chain stitch sewing

pp woven bag stitching machine

The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency

The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency The ability to mold FRP into various configurations allows for customized solutions that can optimize space and improve flow efficiency