-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

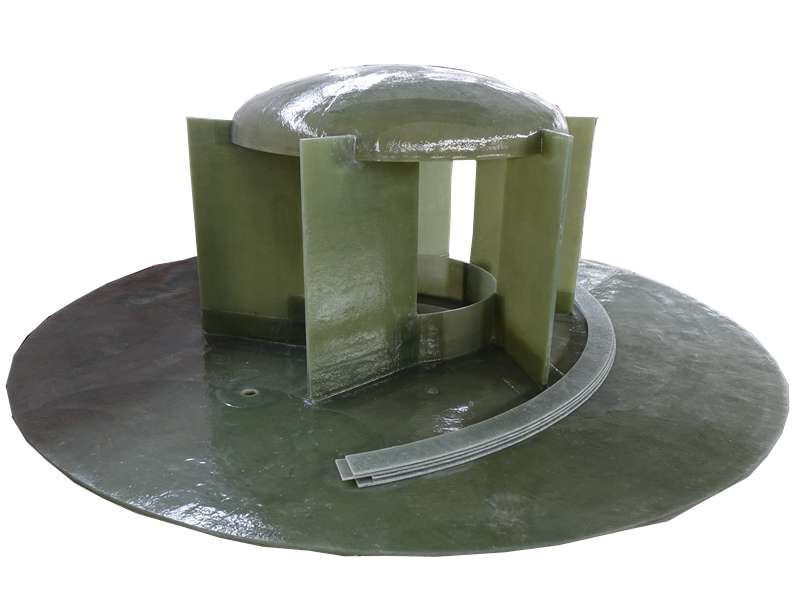

Other Products

Main process includes hand lay-up process, vacuum infusion process, winding, etc.

Because of its corrosion resistance and versatility, fiberglass reinforced plastic (FRP) is a popular material for many different industries like chemical and pharmaceutical engineering, semiconductor production, refineries and paper mills, etc.

If use the food grade resin, the fiberglass products can also be used for drinking water, food, say sauce, fermentation, wine, etc.

The detailed features of fiberglass customized products are like below:

- Good performance to resist the corrosion from chemical and environmental medium;

- Good mechanical performance and light weight;

- Long life and no need of maintenance;

- Good performance of water proof;

- No deformation and good stability;

- Rich color and beautiful appearance;

- Easy and quick installation;

Except the pure fiberglass products, Jrain offers linings for steel equipment, flue gas ducts and tanks which are used in numerous industrial sectors, e.g. pharmaceutical and chemical processing, energy production and waste incineration.

Jrain have been designing and fabricating these types of custom products for many years, including many products with complex curves and tight tolerance.

With 3 D design software and well-equipped wood working/mould building department, Jrain is capable of taking on even the most ambitious custom made fiberglass projects.

In addition, plant installation and on-site service complete our range of services with regard to project implementation. Our customer proximity allows us to react in a flexible and fast manner concerning repairs and maintenance of customer production lines and facilities.

Jrain’s experienced and qualified employees as well as our quality management ensure that all works are performed in compliance with high quality standards.