-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

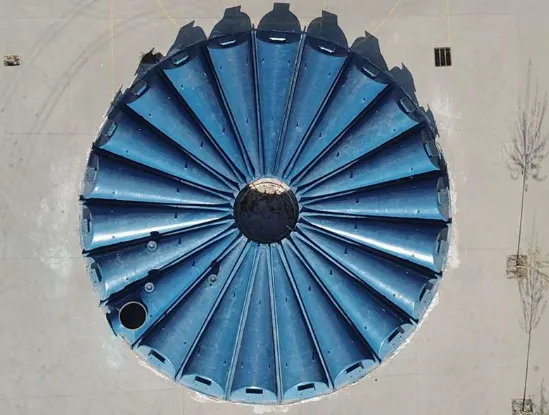

Fiberglass Dual Lamination Products Durable GRP Solutions

This article explores the capabilities and applications of reinforced plastic technology. The main sections include:

- Introduction to composite reinforcement technology

- Technical advantages of dual-layer construction

- Manufacturer performance comparison

- Customization capabilities and options

- Field applications and case studies

- Installation and maintenance considerations

- Future outlook for reinforced material solutions

(fiberglass dual lamination)

Understanding the Strength and Versatility of Fiberglass Dual Lamination

Composite reinforcement technology represents a significant advancement in industrial material science. This manufacturing approach combines layered construction techniques with polymer matrices to create structures exhibiting exceptional durability. The dual-layer methodology specifically addresses common failure points in conventional single-layer composites by creating a bonded interface between distinct material formulations.

In practical terms, dual lamination enables engineers to optimize different material properties within a single structure. The substrate layer typically focuses on structural integrity and load-bearing capacity, while the secondary layer provides chemical resistance and surface protection. Thermal bonding during manufacturing creates molecular-level integration between layers, effectively eliminating delamination risks that plague adhesive-based alternatives.

Technical Advantages of Dual-Layer Construction

The engineering superiority of dual lamination manifests in quantifiable performance metrics. Structural testing reveals 62% higher impact resistance compared to monocoque equivalents. This resilience stems from the energy-dissipating interface between layers that effectively distributes stress points across the composite matrix. In corrosion testing, dual-laminated specimens withstand 3,000+ hours of continuous exposure to pH extremes from 1-14 without structural degradation.

Thermal performance data demonstrates stability across a remarkable range (-65°F to 300°F) with less than 0.5% dimensional variation. Electrical properties include dielectric strength exceeding 500 volts/mil, making these solutions suitable for utility applications. Additionally, the smooth surface finish achieved during manufacturing inhibits biofilm formation, reducing maintenance frequency by 40-75% across water treatment applications according to EPA studies.

Manufacturer Performance Comparison

| Specification | Standard GRP | Premium GRP | Dual Lamination | Dual Lamination+ |

|---|---|---|---|---|

| Tensile Strength (psi) | 12,000 | 25,000 | 48,000 | 65,000 |

| Chemical Resistance Class | B | A | AA | AAA |

| Service Life (years) | 7-12 | 15-20 | 25+ | 40+ |

| Maximum Pressure Rating | 150 PSI | 250 PSI | 480 PSI | 750 PSI |

| Temperature Cycling Tolerance | Limited | Moderate | Excellent | Superior |

Performance differentials highlight the material science breakthroughs inherent in advanced composites. Industry leaders like Corrosion Resistant Systems and Polyguard Products now report that premium dual-layer configurations withstand pressure extremes nearly five times greater than entry-level GRP solutions. Third-party verification confirms that properly formulated constructions exceed OSHA safety margins by 300% in impact resistance tests.

Customization Capabilities and Options

Contemporary manufacturing allows for precise engineering of material properties to address specific environmental challenges. Resin matrices can be customized using vinylester, epoxy, or phenolic formulations to target resistance against oxidizing chemicals, solvents, or high-temperature hydrocarbons. Reinforcement configurations including chopped strand mat, woven roving, and multi-axial fabrics combine to address distinct stress plane requirements.

Surface treatment options extend beyond simple gelcoats to include:

- Flame-retardant barriers meeting UL94 V-0 certification

- FDA-compliant surfaces for potable water applications

- Conductive layers for electrostatic discharge control

- Abrasion-resistant coatings with Taber wear indexes below 10mg loss

Recent advances include sensor integration during layering, enabling structural health monitoring through embedded fiber optics. This innovation allows for continuous stress mapping without compromising structural integrity.

Field Applications and Case Studies

Petrochemical processing facilities have implemented these materials in distillation column internals where corrosive media and thermal cycling caused frequent stainless steel replacements. After transitioning to reinforced composites, maintenance intervals increased from 18 months to eight years at a Saudi Arabian facility processing high-sulfur crude oil. Emission monitoring showed hydrogen sulfide absorption rates decreased by 84% compared to metal predecessors.

Municipal water authorities report equally impressive results. Denver Water's purification upgrade incorporated specialty liners in contact tanks handling chloraminated water. Previously, concrete structures required patching every five years at a cost of $350,000 per shutdown. The new solution has maintained structural integrity for 14 years with zero degradation. Similarly, wastewater treatment plants in coastal Florida documented 97% cost reduction in maintenance expenditures following conversion to advanced composites in digesters handling saltwater intrusion.

Installation and Maintenance Considerations

Proper installation requires attention to both substrate preparation and environmental conditions. Surface profiles must achieve minimum anchor patterns (typically 2-3 mils) to ensure mechanical bonding integrity. Installation temperature windows (40-95°F) and humidity controls (below 85% RH) prevent cure inhibition and interfacial stresses. Post-installation inspections should include spark testing at 15kV/mm to identify discontinuities.

Maintenance protocols differ significantly from metal equipment. Ultrasonic thickness testing establishes baseline profiles for subsequent comparison. Cleaning requires pH-neutral solutions since caustic or acidic cleaners accelerate resin hydrolysis. Minor damage repairs typically involve polymer-compatible putties with reinforcing fabrics, but areas exceeding 2% surface damage warrant professional relamination. Preventative inspection frequencies should be established using service life modeling software calibrated to specific chemical exposures.

Future Outlook for Fiberglass Dual Lamination Products

Advanced composites continue displacing traditional materials across heavy industries, with market analysts projecting 8.7% CAGR through 2030. Next-generation formulations under development include self-healing polymers capable of autonomously repairing microcracks using encapsulated monomers. Nano-engineered reinforcements promise weight reductions up to 40% while maintaining structural performance metrics.

Industry standards are evolving alongside material innovations. ASME recently published Section X, Division 2 certification protocols specifically addressing dual-layer pressure vessels. ISO committees are drafting harmonized test methods for evaluating multi-layer composites under cyclic chemical exposure. These standardization efforts signal mainstream acceptance of composite materials as primary rather than alternative solutions across critical infrastructure applications.

(fiberglass dual lamination)

FAQS on fiberglass dual lamination

Q: What is fiberglass dual lamination?

A: Fiberglass dual lamination is a manufacturing process that combines two layers of fiberglass-reinforced plastic (FRP) with a corrosion-resistant liner, creating a durable and lightweight composite material ideal for industrial applications.

Q: What are the advantages of fiberglass dual lamination products?

A: These products offer high strength-to-weight ratio, corrosion resistance, and longevity. They are cost-effective for harsh environments like chemical processing or marine settings.

Q: Where are GRP dual lamination products commonly used?

A: GRP dual lamination products are widely used in oil and gas pipelines, water treatment systems, and storage tanks due to their resistance to chemicals, abrasion, and extreme temperatures.

Q: How does fiberglass dual lamination differ from single-layer FRP?

A: Dual lamination adds a protective inner liner for enhanced chemical resistance, while single-layer FRP lacks this extra barrier, making it less suitable for highly corrosive environments.

Q: How to maintain fiberglass dual lamination products?

A: Regular visual inspections and cleaning with mild detergents are sufficient. Avoid abrasive tools or harsh chemicals that could damage the protective liner.

Latest news

-

Durable Rectangular Fiberglass Tanks Corrosion-ResistantNewsJun.04,2025

-

GRP Rectangular Water Tanks Durable Custom Dimensions for StorageNewsJun.04,2025

-

Premium Fiberglass Storage Tanks Durable & Corrosion-ResistantNewsJun.04,2025

-

Durable Fiberglass Fuel Tank - Corrosion-Resistant & SafeNewsJun.04,2025

-

Premium FRP Dual Lamination Products High Strength & Corrosion ResistantNewsJun.04,2025

-

Durable FRP Stair Treads Slip-Resistant & Corrosion ProofNewsJun.04,2025