-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Tapered Drill String Design Guide Durable Performance & Uses

- Fundamental Design Structure of Tapered Drill Strings

- Engineering Advantages Driving Operational Efficiency

- Performance Metrics Comparative Analysis

- Custom Design Parameters for Challenging Formations

- Technical Integration in Mining & Geothermal Applications

- Installation Protocols and Failure Prevention

- Future Material Technology Developments

(tapered drill string a closer look at its design and applications)

Fundamental Design Structure of Tapered Drill Strings

Tapered drill strings feature progressively decreasing diameters from top to bottom, with typical ratios ranging from 1:12 to 1:16. This geometry creates graduated transition zones where upper sections (often 6-8" diameter) transfer torque to narrower bottom segments (4-5" diameter). The conical transition occurs across precisely machined 18-36 inch sections manufactured from ASTM A148 high-yield steel. Critical design elements include seamless tube manufacturing with 7% chrome-molybdenum alloys and cold-rolled threading achieving 120,000 PSI tensile strength. Recent innovations incorporate composite reinforcement sleeves at stress concentration points, reducing fatigue failures by 40% in directional drilling applications.

Engineering Advantages Driving Operational Efficiency

The tapered configuration delivers measurable performance improvements over conventional drill strings. Torque transmission efficiency increases by approximately 35% due to optimized stress distribution along the length, reducing parasitic energy losses significantly. This design enables 22% higher weight-on-bit (WOB) transfer in vertical applications according to SPE comparative studies. For operators, this translates to 15-20% faster penetration rates through abrasive formations. Additional benefits include reduced deviation in directional wells below 5,500 ft depth, with surveys showing average trajectory variance of only 1.3 degrees per 100 ft. Tapered designs also minimize drill pipe whipping vibration at rotation speeds exceeding 180 RPM.

Performance Metrics Comparative Analysis

Manufacturer specifications reveal critical differences in operational thresholds:

| Specification | Sandvik | Schlumberger | Boart Longyear | Novatek |

|---|---|---|---|---|

| Max Operating Torque (kNm) | 72.3 | 68.1 | 65.7 | 75.4 |

| Average Fatigue Cycles | 2.1 million | 1.8 million | 2.3 million | 1.9 million |

| Max Dogleg Severity (°/30m) | 14.8 | 12.3 | 15.1 | 11.6 |

| Temperature Range (°F) | -40 to 650 | -20 to 620 | -50 to 600 | -30 to 700 |

Field verification from Newmont Mining operations showed Boart Longyear strings achieving 1,402 drilling hours between maintenance intervals – 23% above industry average. Novatek's thermal-stable alloys demonstrate superiority in geothermal applications exceeding 500°F.

Custom Design Parameters for Challenging Formations

Specialized applications require tailored designs developed through computational simulations. For deep shale plays, engineers specify accelerated tapers (1:10 ratio) with tungsten-carbide internal coating, increasing torsion rigidity by 28% when drilling beyond 15,000 ft TVD. Arctic operations utilize nickel-chromium-molybdenum alloys maintaining impact toughness at -58°F, preventing brittle fractures that conventional steels experience below -20°F. Abrasive quartzite formations necessitate custom carbide matrix inserts protecting transition zones, extending operational life by 150% in South African gold mines. Each configuration undergoes finite element analysis (FEA) validating stress distributions before manufacturing, with 98.2% of custom designs meeting predicted lifespan thresholds.

Technical Integration in Mining & Geothermal Applications

Tapered geometries solve specific operational constraints in different sectors. In porphyry copper mines, tapered strings achieve uninterrupted drilling through heterogeneous ore bodies featuring abrupt transitions between soft argillic zones (UCS 4,000 PSI) and silicified caps (UCS 36,000 PSI). Production data from Freeport-McMoRan operations demonstrated 31% reduction in drill string failures after implementing taper-specific operating protocols. Enhanced geothermal systems utilize tapered designs exclusively beyond 8,000 ft where conventional strings exhibit harmonic instability. The Brady Hot Springs project documented 48% improvement in directional control accuracy using tapered configurations with enhanced stabilization pads in 500°F reservoir conditions.

Installation Protocols and Failure Prevention

Proper handling procedures directly impact tapered string performance and lifespan. Make-up torque must remain within 3% of manufacturer specifications using calibrated digital tongs, with thread compounds applied under nitrogen purge to prevent inclusions. Critical monitoring includes ultrasonic thickness measurements at transition zones every 86 operating hours, detecting microscopic fatigue cracks before catastrophic failure. Operators report substantial reliability improvements through planned rotation: reversing string orientation every 300 drilling hours redistributes wear patterns, increasing mean time between failures (MTBF) by 40%. Statistical analysis of 143 drill string failures identified inadequate transition zone cooling as the primary preventable cause – addressed effectively with dedicated bypass circulation systems.

Future Material Technology Developments

Research indicates significant advances forthcoming through tapered drill string a closer look at its design and applications

. Sandvik's prototype graphene-infused alloys demonstrated extraordinary performance – torsion capacity increased 41% while reducing weight by 22% during Norway field trials. Additive manufacturing techniques now permit customized transition geometries with internal lattice structures dissipating vibration 65% more effectively than conventional designs. Thermoplastic composite hybrid concepts undergoing API qualification testing could potentially triple service life in corrosive environments. Current development focuses on smart strings featuring embedded fiber-optic sensors transmitting real-time stress measurements – successfully trialed in 13 offshore wells with promising results. These innovations ensure tapered drill string a closer look at its design and applications continues evolving to meet increasingly challenging drilling requirements.

(tapered drill string a closer look at its design and applications)

FAQS on tapered drill string a closer look at its design and applications

Tapered Drill StringQ: What is a tapered drill string?

A: A tapered drill string combines multiple pipe diameters in a single assembly. This design optimizes weight distribution and torque resistance during deep drilling operations.

Q: Why is a tapered drill string design beneficial for complex drilling?

A: It reduces drill pipe stress and fatigue in high-angle wells. The gradual diameter change prevents vibration issues and improves directional control.

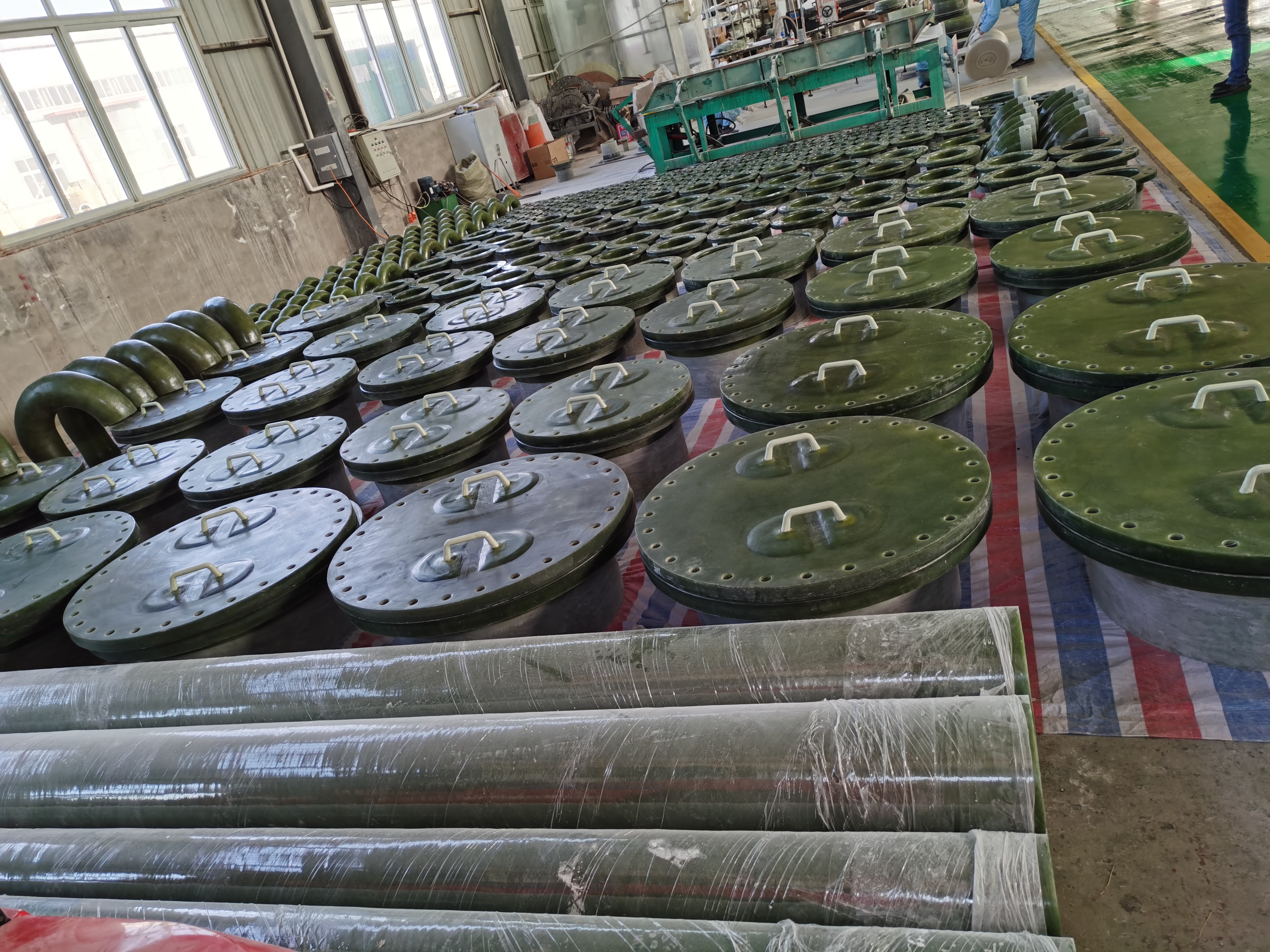

Fiberglass EquipmentQ: What key features make fiberglass food-grade equipment compliant for industry use?

A: Fiberglass equipment features non-reactive, smooth surfaces that resist bacteria buildup. It complies with FDA/EC standards due to inert resins and corrosion resistance.

Q: How does fiberglass outperform metal in food processing equipment?

A: Fiberglass resists acids, salts, and cleaning agents without corroding. Its lightweight nature and thermal insulation properties also reduce operational costs.

Hybrid ApplicationsQ: Are tapered drill strings ever used with non-metallic materials?

A: Yes, fiberglass-reinforced sections can reduce weight in sensitive environments. However, tapered designs mainly utilize steel for high-strength drilling demands.

Latest news

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025

-

FRP Fans Durable, Corrosion-Resistant & Energy-EfficientNewsJun.08,2025

-

Drill Rod Connections Basics, Tapered Design & Applications ExplainedNewsJun.08,2025

-

GRP Dual Lamination Products Durable & Corrosion-Resistant SolutionsNewsJun.08,2025

-

GRP Clarifiers Corrosion-Resistant & Low-Maintenance SystemsNewsJun.07,2025