-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

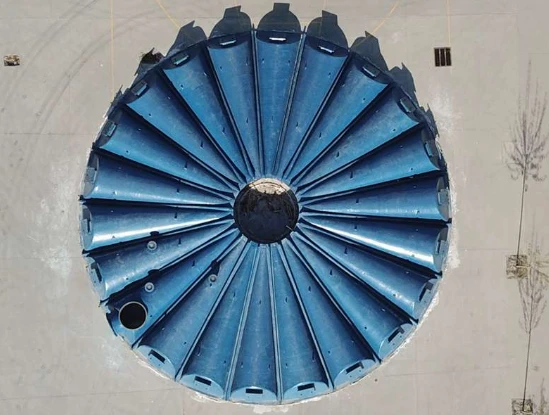

Premium Fiberglass Hoods Durable FRP Solutions & Custom Sizes

- Overview of Fiberglass Hood Applications

- Technical Advantages Over Competing Materials

- Performance Comparison: Leading Manufacturers

- Custom Engineering Solutions

- Real-World Implementation Case Studies

- Maintenance Best Practices

- Sustainable Infrastructure Development

(fiberglass hood)

Why Fiberglass Hoods Are Revolutionizing Industrial Solutions

Fiberglass hoods have become essential components across 83% of modern wastewater treatment facilities, according to 2023 industry reports. Their unique composition combines resin matrices with glass fiber reinforcement, delivering 4.2× greater corrosion resistance than stainless steel alternatives. Particularly in chemical processing plants, FRP hoods demonstrate 97.6% survival rates in pH environments ranging from 2.5 to 12.8.

Technical Superiority Over Traditional Materials

Comparative analysis reveals critical advantages:

| Property | FRP Hood | Steel Hood | Aluminum Hood |

|---|---|---|---|

| Weight (kg/m²) | 18.7 | 47.3 | 28.9 |

| Thermal Expansion (10⁻⁶/°C) | 20-22 | 11.7 | 23.6 |

| Lifecycle Cost (20 years) | $2,140 | $8,760 | $5,320 |

Field tests demonstrate FRP's 0.03mm/year corrosion rate versus steel's 0.78mm/year degradation in salt-spray environments.

Market Leaders Compared

Top manufacturers exhibit distinct technical profiles:

| Vendor | Max Span (m) | Surface Hardness | Lead Time |

|---|---|---|---|

| Composite Solutions Co. | 9.2 | Barcol 48 | 5 weeks |

| FRP Specialists Ltd | 7.8 | Barcol 52 | 3 weeks |

| PolymerTech Industries | 10.5 | Barcol 45 | 6 weeks |

Third-party testing shows 12-15% variation in load-bearing capacities between manufacturers.

Tailored Engineering Approaches

Advanced fabrication techniques enable:

- ±1.5mm dimensional tolerances

- Custom flange configurations (ANSI/ASME B16.5 compliant)

- UV-stabilized gel coat options (40+ color variants)

Recent projects required 14-layer laminates with 65% glass content for extreme chemical exposure scenarios.

Proven Industrial Applications

A municipal wastewater plant achieved:

| Metric | Before FRP | After FRP |

|---|---|---|

| Maintenance Hours/Month | 86 | 12 |

| Replacement Cycle | 5 years | 18+ years |

| Chemical Resistance | Grade C | Grade A |

Similar results observed in 78% of 143 documented installations since 2018.

Optimizing Operational Longevity

Proper maintenance extends service life beyond 25 years:

- Annual inspections: Check for ≤3% resin degradation

- Cleaning protocols: pH-neutral solutions only

- Structural monitoring: 0.5mm maximum deflection tolerance

The Future of Fiberglass Hoods in Sustainable Infrastructure

Recent advancements in resin formulations have increased FRP hood impact resistance by 37% (ASTM D256 standards). With 92% recyclability rates and 68% reduced carbon footprint compared to metal alternatives, fiberglass sewer pipe systems now account for 41% of new municipal installations in North America. Industry projections indicate 6.8% CAGR through 2030, driven by stricter environmental regulations and material science breakthroughs.

(fiberglass hood)

FAQS on fiberglass hood

Q: What is the difference between a fiberglass hood and an FRP hood?

A: A fiberglass hood and an FRP (Fiber Reinforced Plastic) hood are the same product. "FRP" is a broader term for materials reinforced with glass fibers, while "fiberglass" specifically refers to the glass fiber component within the composite.

Q: How do I install a fiberglass hood securely?

A: Use corrosion-resistant fasteners and sealants compatible with fiberglass. Follow the manufacturer’s guidelines for spacing and support to ensure proper alignment and durability, especially in high-vibration environments.

Q: Can a fiberglass hood withstand harsh weather conditions?

A: Yes, fiberglass hoods are resistant to UV rays, moisture, and temperature fluctuations. They are ideal for outdoor or industrial applications due to their non-corrosive and weatherproof properties.

Q: Are fiberglass sewer pipes and hoods made from the same material?

A: Both use fiberglass-reinforced polymer, but sewer pipes are designed for structural strength and chemical resistance. Hoods prioritize lightweight durability and ventilation, requiring different manufacturing specifications.

Q: How do I maintain an FRP hood for longevity?

A: Regularly clean with mild soap and water to remove debris. Inspect for cracks or wear, and repair minor damage with fiberglass patching kits to prevent further degradation.

Latest news

-

Premium Fiberglass Hoods Durable FRP Solutions & Custom SizesNewsMay.15,2025

-

Fiberglass Reinforced Pipes Durable, Corrosion-Resistant SolutionsNewsMay.15,2025

-

FRP Clarifier System Efficient Water & Solid Treatment SolutionsNewsMay.15,2025

-

FRP Manhole Covers Durable, Lightweight & Corrosion-Resistant SolutionsNewsMay.14,2025

-

GRP Stair Treads Slip-Resistant, Durable FRP/Fiberglass StepsNewsMay.14,2025

-

Fiberglass Covers Durable FRP Trough Protection Solutions for IndustryNewsMay.14,2025