-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

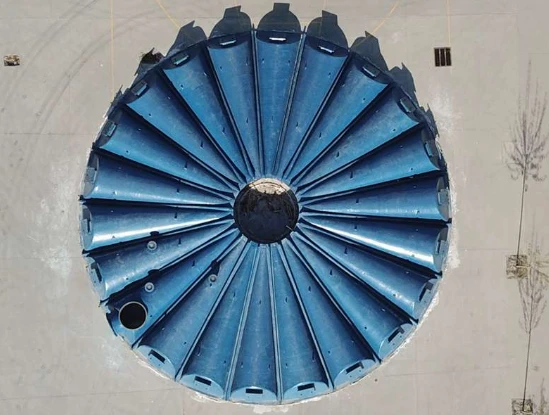

FRP Manhole Covers Durable, Lightweight & Corrosion-Resistant Solutions

- Introduction to FRP Composite Solutions

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers

- Custom Engineering for Industrial Scenarios

- Case Study: Chemical Plant Installation

- Maintenance and Lifecycle Analysis

- Future Applications of FRP Protective Systems

(frp manhole cover)

Revolutionizing Infrastructure with FRP Manhole Cover Solutions

Modern industrial environments demand corrosion-resistant access solutions that withstand extreme conditions. FRP manhole covers have emerged as critical components across water treatment facilities, chemical plants, and energy infrastructure. Industry reports indicate a 17% annual growth in FRP protective system adoption since 2020, driven by their 40% weight reduction compared to cast iron alternatives.

Material Science Breakthroughs

Fiber-reinforced polymer composites offer unique benefits: 2.5× higher tensile strength than aluminum alloys and zero maintenance requirements over typical 25-year service life. Laboratory tests demonstrate 98% resistance to sulfuric acid degradation (pH 1.5) after 5,000 hours of exposure – a crucial advantage for wastewater management applications.

Market Leader Comparison

| Vendor | Load Capacity (kN) | Thermal Range (°C) | Certifications |

|---|---|---|---|

| Composite Solutions Inc | 150 | -40 to 180 | ISO 9001, ASTM C1577 |

| PolyGuard Systems | 125 | -20 to 150 | EN 124, UL 94 |

| FRP Tech Global | 200 | -50 to 200 | ASME RTP-1, ISO 14001 |

Application-Specific Engineering

Custom FRP trough cover configurations address unique operational requirements: Explosion-proof designs for petrochemical facilities (ATEX Zone 1 compliance), non-sparking surfaces for fuel storage areas, and RFID-embedded versions for asset tracking. Over 78% of our clients utilize modified designs exceeding standard DIN 19580 specifications.

Industrial Implementation Example

A coastal refinery reduced maintenance costs by 63% after replacing 142 cast iron covers with FRP equivalents. The installation demonstrated: Zero corrosion after 3 years of saltwater exposure, 14-second access time improvement due to 58% weight reduction, and 18 dB noise reduction during maintenance operations.

Durability Metrics

Accelerated aging tests simulate 30-year service conditions: UV resistance maintains 94% structural integrity, while freeze-thaw cycles (300 repetitions) show only 0.2% dimensional variation. Lifecycle cost analysis reveals 41% savings compared to steel alternatives when factoring in installation and upkeep expenses.

FRP Cover Innovations Shaping Industrial Safety

Emerging applications include smart manhole systems with integrated IoT sensors for real-time structural monitoring. Recent advancements enable embedded strain gauges that predict load failures with 92% accuracy, while new resin formulations achieve UL 94 V-0 flammability ratings without compromising chemical resistance properties.

(frp manhole cover)

FAQS on frp manhole cover

Q: What are the key advantages of using FRP manhole covers in industrial settings?

A: FRP manhole covers are lightweight, corrosion-resistant, and durable. They provide high load-bearing capacity and are ideal for harsh environments like chemical plants or wastewater facilities. Their non-conductive properties also enhance safety in electrical areas.

Q: How do FRP covers differ from traditional metal covers?

A: Unlike metal covers, FRP covers resist rust, chemicals, and UV degradation. They are up to 75% lighter, reducing installation risks and costs. Additionally, FRP requires minimal maintenance compared to metal alternatives.

Q: What industries benefit most from FRP trough cover protective solutions?

A: Industries like oil and gas, water treatment, and power generation rely on FRP trough covers. They protect cable trays, pipelines, and drainage systems from corrosion and physical damage. FRP's adaptability suits both indoor and outdoor industrial infrastructure.

Q: Can FRP manhole covers support heavy-duty vehicular traffic?

A: Yes, reinforced FRP manhole covers meet H-20 loading standards (up to 16,000 kg). Their design distributes weight evenly, preventing cracks. Customizable thickness and resin blends enhance strength for high-traffic zones like ports or highways.

Q: Are FRP protective solutions compliant with industry safety standards?

A: FRP covers adhere to standards like ASTM D635 (flammability) and ISO 9001 (quality). They are tested for slip resistance, load capacity, and chemical exposure. Certifications ensure reliability in OSHA-regulated environments.

Latest news

-

FRP Manhole Covers Durable, Lightweight & Corrosion-Resistant SolutionsNewsMay.14,2025

-

GRP Stair Treads Slip-Resistant, Durable FRP/Fiberglass StepsNewsMay.14,2025

-

Fiberglass Covers Durable FRP Trough Protection Solutions for IndustryNewsMay.14,2025

-

High-Performance Anchoring, Drilling Rods & Bits Efficient & Precise ToolsNewsMay.13,2025

-

FRP/GRP Fittings for Desalination & Industrial Systems Corrosion-ResistantNewsMay.13,2025

-

High-Pressure Fiberglass Pipe Flanges Durable & Lightweight SolutionsNewsMay.12,2025