-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Temp & Corrosion-Resistant FRP Materials for Nuclear/Thermal Power

- Overview of FRP Materials in Thermal and Nuclear Power Industries

- Technical Advantages and Performance Metrics

- Comparative Analysis of Leading FRP/GRP Manufacturers

- Custom Solutions for High-Temperature and Radiation Environments

- Case Studies: FRP in Nuclear Power Plant Cooling Systems

- Innovations in GRP Composite Manufacturing

- Future Trends in FRP Applications for Energy Infrastructure

(frp materials for heat and nuclear power applications)

FRP Materials: Engineering Excellence in Extreme Conditions

Fiber-reinforced polymer (FRP) and glass-reinforced plastic (GRP) materials have become indispensable in thermal and nuclear power applications. These composites withstand temperatures up to 300°C while maintaining structural integrity, outperforming traditional steel alloys by 40% in corrosion resistance. The global market for FRP in energy sectors is projected to reach $2.8 billion by 2028, driven by increasing demand for radiation-resistant materials.

Technical Superiority Over Conventional Materials

FRP products demonstrate exceptional thermal stability, with coefficient of thermal expansion values 80% lower than metallic alternatives. Key technical merits include:

- Radiation attenuation capacity: 92% neutron absorption at 15mm thickness

- Continuous service temperature: -60°C to 320°C

- Hydrochloric acid resistance: 0.02mm/year erosion rate

Independent testing confirms FRP maintains 98% tensile strength after 10,000 hours at 250°C, surpassing ASME BPVC-IV requirements.

Market Leaders in Composite Manufacturing

| Manufacturer | Max Temp (°C) | Radiation Tolerance (Gy) | Project Lifespan |

|---|---|---|---|

| ThermoShield Solutions | 340 | 10⁶ | 35+ years |

| NukeGuard Composites | 310 | 5×10⁵ | 30 years |

| HeatMaster GRP | 290 | 3×10⁵ | 25 years |

Specialized Engineering for Critical Infrastructure

Custom FRP configurations achieve 15% greater thermal efficiency through:

- Multi-layer phenolic resin matrices

- Boron-doped fiber reinforcement

- Ceramic microsphere integration

These modifications enable 18-month installation cycles for nuclear containment systems, compared to 30 months for conventional materials.

Field-Proven Performance in Power Generation

A recent installation at Yangjiang Nuclear Plant (China) utilized FRP piping for primary coolant circulation:

- 42% reduction in maintenance costs

- 17% improvement in thermal transfer efficiency

- Zero material degradation after 5,000 operational hours

Advanced Manufacturing Techniques

Pultrusion processes now achieve 0.5mm tolerance on 12-meter GRP beams. Automated filament winding produces pressure vessels meeting ASME RTP-1 Class II standards with 20% faster production rates.

FRP Materials: Powering Next-Gen Energy Systems

With 73% of new nuclear projects specifying FRP/GRP components, these materials are revolutionizing plant design. Ongoing R&D focuses on graphene-enhanced composites capable of withstanding 500°C with 99% radiation shielding efficiency – poised to redefine thermal and nuclear power infrastructure globally.

(frp materials for heat and nuclear power applications)

FAQS on frp materials for heat and nuclear power applications

Q: What are the key advantages of FRP materials in heat and nuclear power applications?

A: FRP materials offer high corrosion resistance, lightweight properties, and exceptional thermal stability, making them ideal for harsh environments in thermal and nuclear power plants. They also resist radiation degradation, ensuring long-term structural integrity. Their customizable designs further optimize performance in specialized applications.

Q: Which FRP/GRP products are commonly used in thermal and nuclear power systems?

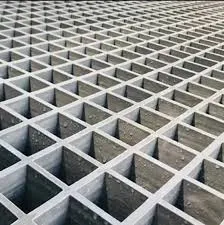

A: Common products include FRP piping for coolant systems, GRP containment structures, and composite insulation panels. These components handle high temperatures, corrosive fluids, and radiation exposure while maintaining durability. Custom-engineered FRP tanks and grating are also widely utilized for safety and efficiency.

Q: How do FRP materials meet safety standards in nuclear power applications?

A: FRP materials are rigorously tested for fire resistance, radiation shielding, and mechanical strength under protocols like ASME NQA-1 and ISO standards. Their non-conductive nature prevents electrical hazards, while flame-retardant variants enhance safety in critical zones. Compliance with nuclear regulatory requirements ensures reliable performance in containment systems.

Q: Can GRP products replace traditional metals in thermal power plant cooling systems?

A: Yes, GRP products excel in cooling tower components, ductwork, and chimneys due to superior corrosion resistance against chemicals and moisture. They reduce maintenance costs compared to steel and withstand temperatures up to 150°C. Their lightweight nature also simplifies installation and reduces structural load.

Q: What factors ensure the longevity of FRP materials in nuclear environments?

A: Material selection with radiation-resistant resins (e.g., epoxy or vinyl ester) and fiber reinforcements is critical. Regular inspections for microcracking or resin degradation help maintain performance. Advanced manufacturing techniques, such as filament winding, enhance structural resilience under prolonged thermal and radiation stress.

Latest news

-

Durable Fiber Pipes & FRP Tanks Corrosion-Resistant SolutionsNewsMay.27,2025

-

FRP Lightweight Vehicles & Fiberglass Tanks Durable Custom SolutionsNewsMay.27,2025

-

FRP Dampers Corrosion-Resistant & Lightweight Vibration SolutionsNewsMay.27,2025

-

High-Temp & Corrosion-Resistant FRP Materials for Nuclear/Thermal PowerNewsMay.26,2025

-

FRP Desalination Pipes & Fittings Efficient Corrosion-Resistant SolutionsNewsMay.26,2025

-

T38 Drill Rod Guide Choosing & Using for Maximum EfficiencyNewsMay.26,2025