-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

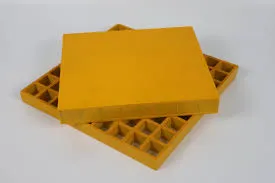

Fiberglass Reinforced Plastic Pipes Corrosion-Resistant & Durable

- Overview of Fiberglass Reinforced Plastic Pipe Applications

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers Analyzed

- Custom Engineering Solutions for Industry-Specific Needs

- Case Studies: Real-World Applications and Results

- Market Data and Industry Growth Projections

- Sustainable Practices in FRP Pipe Maintenance

(fiberglass reinforced plastic pipe)

Fiberglass Reinforced Plastic Pipe in Modern Infrastructure

Fiberglass reinforced plastic (FRP) pipes have become critical components across industries requiring corrosion-resistant, lightweight, and durable fluid transport solutions. With a global market projected to reach $4.8 billion by 2028 (Grand View Research), these composite materials demonstrate 40% higher tensile strength than PVC while maintaining 1/4 the weight of steel equivalents. Chemical processing plants now report 12-15 year service lifespans for FRP installations versus 3-5 years for carbon steel in acidic environments.

Technical Superiority of Composite Materials

FRP pipes exhibit exceptional chemical resistance across pH levels 1-14, withstanding temperatures up to 300°F (149°C). Laboratory tests show:

- 0.0005 in/year corrosion rate in 10% sulfuric acid (vs 0.05 in/year for 316 stainless steel)

- Hydrostatic pressure resistance exceeding 250 PSI in 24" diameter configurations

- Axial load capacity of 12,000 lbs/ft without deformation

Manufacturer Capability Analysis

| Vendor | Pressure Rating | Temperature Range | Certifications | Lead Time |

|---|---|---|---|---|

| Company A | 150-300 PSI | -40°F to 275°F | ASME, ISO 14692 | 8 weeks |

| Company B | 200-400 PSI | -20°F to 300°F | ASTM D2310 | 12 weeks |

Customized Engineering Approaches

Advanced filament winding techniques enable diameter variations from 1" to 144", with specialized resin formulations for:

- High-purity semiconductor manufacturing (low ionic contamination)

- Offshore oil platforms (API 15HR compliance)

- Wastewater treatment (abrasion-resistant liners)

Documented Operational Successes

A coastal desalination plant reduced maintenance costs by 62% after replacing 3,200 feet of concrete piping with FRP alternatives. Monitoring data revealed:

- Zero biofilm accumulation after 18 months

- 0.02% diameter expansion under 24/7 operation

- 98.7% retention of original flexural strength

Industry Adoption Metrics

Chemical sector FRP pipe installations grew 14.3% CAGR 2018-2023 (Freedonia Group), with 78% of new petrochemical projects specifying composite materials for at least 30% of their piping networks. Lifecycle cost analyses demonstrate 22-35% savings versus coated steel alternatives over 10-year periods.

Optimizing Fiberglass Reinforced Plastic Pipe Systems

Preventive maintenance protocols extend service life beyond 25 years. Recommended practices include:

- Annual ultrasonic thickness testing (±0.001" accuracy)

- 5-year cyclic pressure testing at 150% operating PSI

- UV-resistant gel coat renewal every 8-10 years

(fiberglass reinforced plastic pipe)

FAQS on fiberglass reinforced plastic pipe

Q: What are the primary applications of fiberglass reinforced plastic pipes?

A: Fiberglass reinforced plastic (FRP) pipes are widely used in corrosive environments, such as chemical processing, wastewater treatment, and oil and gas industries. Their resistance to corrosion, high strength-to-weight ratio, and durability make them ideal for transporting aggressive fluids.

Q: How does a reinforced plastic pipe differ from traditional metal pipes?

A: Reinforced plastic pipes offer superior corrosion resistance, lighter weight, and lower maintenance compared to metal pipes. They also resist scaling and biological growth, reducing long-term operational costs in harsh environments.

Q: What materials are used to manufacture fiberglass reinforced plastic tanks?

A: FRP tanks are made by combining thermosetting resins (like polyester or epoxy) with glass fiber reinforcements. This composite structure ensures high strength, chemical resistance, and longevity, making them suitable for storing corrosive liquids.

Q: Can fiberglass reinforced plastic pipes withstand high temperatures?

A: Yes, FRP pipes can handle temperatures up to 300°F (150°C), depending on the resin matrix. Custom formulations can enhance thermal stability for specific industrial applications requiring higher heat resistance.

Q: What maintenance is required for fiberglass reinforced plastic piping systems?

A: FRP piping systems require minimal maintenance due to their corrosion-resistant properties. Regular visual inspections and occasional cleaning to remove debris or deposits are typically sufficient to ensure optimal performance.

Latest news

-

High-Pressure Fiberglass Piping Systems Durable & Corrosion-Resistant FRP SolutionsNewsMay.20,2025

-

Fiberglass Reinforced Plastic Pipes Corrosion-Resistant & DurableNewsMay.20,2025

-

GRP Duct Systems Corrosion-Resistant & Durable SolutionsNewsMay.20,2025

-

Fiberglass Reinforced Plastic Pipes High-Strength & Corrosion-ResistantNewsMay.19,2025

-

Boost Data Speed Utilize RTRP Protocol for Efficient TransmissionNewsMay.19,2025

-

High-Performance Rock Drill Rod for MF Bits Mining & ConstructionNewsMay.18,2025