-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

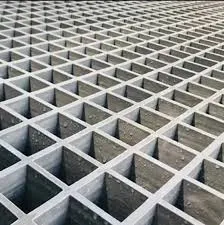

fiberglass dual lamination

Understanding Fiberglass Dual Lamination A Comprehensive Overview

Fiberglass dual lamination is an advanced composite manufacturing process that combines the unique properties of fiberglass and lamination techniques to create durable and lightweight materials. This process finds extensive applications across various industries, including automotive, aerospace, marine, and construction, due to its superior strength-to-weight ratio and corrosion resistance. In this article, we will delve into the fundamentals of fiberglass dual lamination, explore its advantages, applications, and the future of this innovative technology.

What is Fiberglass Dual Lamination?

Fiberglass dual lamination involves layering sheets of fiberglass with a resin system, often reinforced with additional materials to enhance strength and durability. The dual aspect of this process typically refers to two layers of fiberglass being bonded together, often utilizing techniques such as vacuum bagging or resin infusion to ensure an even and robust lamination. The resulting material benefits from the structural integrity of fiberglass and the protective features offered by the resin, which contributes to increased resistance against environmental factors.

Advantages of Fiberglass Dual Lamination

1. High Strength-to-Weight Ratio One of the most significant advantages of fiberglass dual lamination is its exceptional strength-to-weight ratio. This allows manufacturers to produce lightweight structures that do not compromise on strength, making it a preferable choice for industries that prioritize efficiency and performance.

2. Corrosion and Chemical Resistance Fiberglass is inherently resistant to a wide range of chemicals and environmental factors. This makes fiberglass dual laminated products highly effective for use in corrosive environments, such as chemical processing plants and marine applications.

3. Versatility in Design The ability to mold fiberglass into various shapes and sizes allows designers and engineers greater flexibility. Dual lamination techniques enable the creation of complex structures that can meet specific client requirements while maintaining structural integrity.

4. Reduced Maintenance Costs Products made from fiberglass dual lamination typically require less maintenance compared to traditional materials like metal and wood. This not only extends the lifespan of the product but also reduces overall lifecycle costs.

5. Sustainability With increasing concerns about sustainability, fiberglass composites can often be produced with recyclable materials and processes that minimize environmental impact, contributing to greener manufacturing practices.

Applications of Fiberglass Dual Lamination

fiberglass dual lamination

The versatility of fiberglass dual lamination has led to its adoption across various sectors

- Automotive Industry Parts such as body panels, interior components, and structural elements utilize fiberglass lamination for weight reduction while enhancing safety through improved energy absorption during impacts.

- Aerospace Sector In aviation, the demand for lightweight yet robust materials is critical. Fiberglass dual lamination is used in interior panels, fuselage sections, and insulation, contributing to fuel efficiency and performance enhancements.

- Marine Engineering Boats and ships benefit from fiberglass laminated hulls, which deliver buoyancy, strength, and resistance to harsh ocean environments, thereby prolonging vessel life and reducing maintenance needs.

- Construction and Infrastructure Fiberglass laminated materials are increasingly utilized in the building sector for roofing systems, bridge construction, and other applications requiring lightweight and durable solutions that can withstand varying environmental conditions.

The Future of Fiberglass Dual Lamination

As technology advances, fiberglass dual lamination is poised for further evolution. Innovations in resins, reinforcement materials, and additive manufacturing are set to enhance the capabilities of fiberglass composites. Additionally, the growing emphasis on sustainability is likely to drive research into bio-based resins and more eco-friendly production methods.

Moreover, the expansion of electric vehicles (EVs) presents an exciting opportunity for fiberglass dual lamination. As the automotive industry shifts towards lighter materials to improve battery efficiency, the demand for fiberglass composites is expected to rise.

Conclusion

Fiberglass dual lamination represents a significant advancement in material science, providing solutions that meet the demands of modern industries. With its exceptional properties, diverse applications, and a commitment to sustainability, this innovative technology is set to play a crucial role in the future of manufacturing. As industries continue to seek performance, efficiency, and durability, fiberglass dual lamination stands out as a viable and advantageous option for a wide array of applications.

Latest news

-

High-Efficiency PDC Anchor Bits Fast High-Performance DrillingNewsJun.07,2025

-

Durable Corrosion-Resistant GRP Pipes & Fittings for Ship BuildingNewsJun.07,2025

-

Premium GRP Playground Equipment Durable & Safe FunNewsJun.06,2025

-

Premium FRP Storage Tanks - Corrosion Proof Acid ContainmentNewsJun.06,2025

-

FRP Absorber Industrial Noise Control SolutionNewsJun.06,2025

-

Efficient FRP Demister Superior Fog Elimination GearNewsJun.05,2025