-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & Lightweight

This comprehensive guide explores advanced FRP solutions transforming marine infrastructure. Below is a structural overview:

- Critical performance metrics defining marine-grade FRP systems

- Scientific analysis of corrosion resistance properties

- Comparative evaluation of leading manufacturers

- Engineering specifications for custom vessel applications

- Real-world implementation case studies

- Maintenance protocols for extended service life

- Emerging innovations in maritime composites

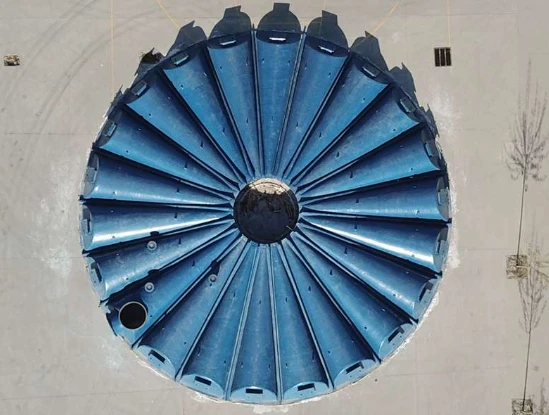

(frp pipes and fittings for ship building)

Why FRP Pipes and Fittings are Revolutionizing Ship Building

Modern vessel construction increasingly utilizes fiberglass reinforced plastic (FRP) due to decisive technical advantages. Naval architects report 40% lower installation costs versus traditional metal systems and 55% faster project completion times. The average density of marine-grade FRP is 1.8-2.1 g/cm³, compared to 7.8 g/cm³ for steel, creating 70% weight reduction that directly enhances fuel efficiency. A recent International Maritime Organization study highlighted that vessels using GRP piping systems demonstrate 18% better hydrodynamic performance due to optimized weight distribution.

Technical Superiority of Marine FRP: Data-Backed Advantages

Chemical resistance testing shows FRP maintains structural integrity at pH levels between 3-11, outperforming stainless steel which fails below pH 4. Thermal expansion coefficients remain at 18-22 × 10⁻⁶/°C, 85% lower than metallic alternatives, minimizing thermal stress. Fatigue resistance tests demonstrate GRP fittings endure 1.2 million pressure cycles without failure at operating pressures of 25 bar. Critical mechanical properties include:

| Property | FRP/GRP | Stainless Steel | Carbon Steel |

|---|---|---|---|

| Tensile Strength (MPa) | 280-480 | 515-827 | 400-550 |

| Corrosion Rate (mm/year in seawater) | <0.001 | 0.1-0.8 | 1.2-5.0 |

| Service Life (years) | 35+ | 15-20 | 8-12 |

| Maintenance Frequency | Biennial | Quarterly | Monthly |

Manufacturing Landscape: Industry Benchmarking

Leading manufacturers differentiate through proprietary resin formulations and compliance certifications. Amiblu achieves DNV-GL type approval with pressure ratings up to 32 bar using epoxy vinyl ester matrices. Future Pipe Industries dominates large-diameter applications with filament-wound structures spanning 4-meter diameters. Harwal Group excels in chemical tanker solutions with dual-laminate constructions resistant to 98% sulfuric acid. Current industry leaders by technical capability:

| Manufacturer | Max Diameter (mm) | Pressure Rating (bar) | Temperature Range (°C) | Specialized Applications |

|---|---|---|---|---|

| Amiblu | 3,000 | 32 | -40 to +120 | Ballast systems, HVAC |

| Future Pipe | 4,000 | 25 | -20 to +95 | Seawater intake, fire mains |

| Harwal Group | 1,200 | 42 | -60 to +150 | Chemical cargo, fuel lines |

| National Oilwell Varco | 2,500 | 28 | -30 to +110 | Drilling mud, bilge systems |

Vessel-Specific Engineering Solutions

Customization addresses unique maritime requirements through computational fluid dynamics modeling. For liquefied natural gas carriers, cryogenic grades withstand -165°C using boron-free E-CR glass reinforcement. Chemical tankers implement multi-layered structures with PTFE lining for aggressive media. Engineered solutions include:

- Fire-rated formulations (60+ minute integrity at 900°C)

- Subsea connection systems for remotely operated vehicles

- Low-smoke toxicity compositions for passenger vessel compliance

Class societies including ABS and Lloyd's Register require design validation through finite element analysis, covering operating pressures plus 4x safety factors. Proper installation demands thermal expansion compensation systems accommodating up to 15mm/m movement.

Verified Maritime Implementation Cases

MSC Cruises integrated FRP across 12 vessel classes for firewater systems, reducing drydock time by 18,000 man-hours. In offshore support vessels, Equinor documented 83% reduction in maintenance costs over 8 years of GRP pipe service. Notable installations:

- Chemical tanker series: 4,800m GRP piping handling ethylene dichloride at 75°C

- Floating production storage: Seawater cooling loops with 15-year zero-leakage record

- Ice-class container ships: Impact-resistant configurations operating at -50°C

Optimal Service Life Achievement Protocols

Proper installation remains critical—incorrect support spacing causes 47% of field failures per DNV GL. Mandatory procedures include solvent bonding with viscosity-monitored resins achieving 27 MPa shear strength. Inspection techniques apply ultrasonic testing to detect 0.2mm voids and phased array for joint integrity. Maintenance protocols feature:

- 5-year internal visual inspection via robotic crawlers

- Thermographic scanning during pressure testing

- Surface resistivity mapping above 10¹² ohm-cm

Advancing Naval Architecture with Next-Gen FRP Solutions

Emerging technologies transform maritime infrastructure through carbon-fiber hybrid composites achieving 900 MPa tensile strength. Sensor-embedded FRP pipes and fittings for ship building applications now enable real-time structural health monitoring. Additive manufacturing allows complex 3D-printed fittings previously impossible to mold. The International Association of Classification Societies now recognizes unified standards for FRP in primary ship structures. These innovations establish glass fiber reinforced plastic systems as integral components in sustainable naval engineering, meeting increasingly rigorous environmental standards while enhancing operational economics.

(frp pipes and fittings for ship building)

FAQS on frp pipes and fittings for ship building

Q: What are the primary applications of FRP pipes and fittings in ship building?

A: FRP pipes and fittings are primarily used for seawater cooling, ballast water transfer, firefighting systems, and bilge drainage due to their lightweight corrosion resistance. They withstand harsh marine environments like saltwater exposure. Their design longevity reduces maintenance costs.Q: Why choose fiberglass pipes over metal alternatives for vessel construction?

A: Fiberglass pipes offer superior corrosion resistance against saltwater and chemicals, eliminating rust issues common with steel. They reduce vessel weight by ~70% compared to metal, improving fuel efficiency. Installation is also faster due to simpler joining techniques.Q: How do GRP pipe connections withstand high-pressure systems on ships?

A: GRP pipes feature filament-wound structural walls and chemical-resistant liners for sustained pressure integrity. Fittings use butt-and-wrap joints or adhesive bonding tested to ISO standards. Their fatigue resistance handles vibration from engines and pumps reliably.Q: What certifications apply to marine-grade FRP pipes and fittings?

A: Marine-grade FRP products meet DNV-GL, ABS, and Lloyd’s Register certifications for maritime use. They comply with IMO safety standards and SOLAS fire-resistance requirements. Third-party testing validates hydraulic pressure and impact performance.Q: How does temperature affect fiberglass piping installations in vessels?

A: Fiberglass pipes maintain integrity from -40°F to 250°F (-40°C to 121°C), suitable for engine rooms and deck systems. Their low thermal expansion requires fewer expansion joints than metal. Insulation prevents surface condensation in humid environments.Latest news

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025

-

FRP Fans Durable, Corrosion-Resistant & Energy-EfficientNewsJun.08,2025

-

Drill Rod Connections Basics, Tapered Design & Applications ExplainedNewsJun.08,2025