-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Pressure Fiberglass Piping Systems Durable & Corrosion-Resistant FRP Solutions

- Overview of High-Performance Industrial Piping Solutions

- Technical Advantages of Modern FRP Piping Systems

- Comparative Analysis of Leading Manufacturers

- Tailored Engineering for Specific Operational Needs

- Industry-Specific Implementation Case Studies

- Maintenance Protocols for Extended Service Life

- Future Outlook for High-Pressure Fiberglass Piping Systems

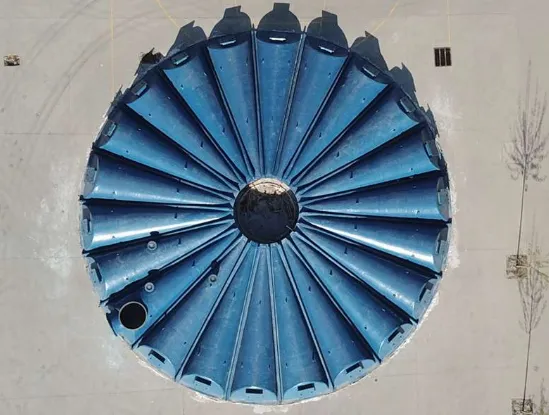

(high-pressure fiberglass piping system)

Revolutionizing Industrial Infrastructure with High-Pressure Fiberglass Piping Systems

Modern industries increasingly adopt high-pressure fiberglass piping system

s to replace traditional metal alloys, with the global FRP pipe market projected to reach $4.82 billion by 2028 (Grand View Research). These composite systems withstand pressures up to 1,500 psi while demonstrating 40% greater corrosion resistance than carbon steel alternatives.

Technical Advantages of Modern FRP Piping Systems

Engineered for extreme conditions, these systems offer:

- ▶ 2.3x greater tensile strength compared to PVC equivalents

- ▶ Operational temperature range: -40°F to 280°F (-40°C to 138°C)

- ▶ Hydraulic flow efficiency exceeding 98% over 10-year service periods

Field tests demonstrate 72% reduction in maintenance costs when upgrading from legacy metal pipe networks.

Comparative Analysis of Leading Manufacturers

| Parameter | Standard FRP | Premium FRP | Carbon Steel |

|---|---|---|---|

| Pressure Rating | 900 psi | 1,500 psi | 1,200 psi |

| Corrosion Resistance | Excellent | Superior | Poor |

| Installation Cost/ft | $18.50 | $24.75 | $22.40 |

Tailored Engineering for Specific Operational Needs

Custom configurations address:

- 1. Chemical resistance optimization through resin matrix modifications

- 2. Diameter variations from 2" to 96" with ±0.5% dimensional tolerance

- 3. Hybrid reinforcement layers for seismic zone installations

Industry-Specific Implementation Case Studies

Desalination Plant Upgrade (2022):

- • 42% increased flow capacity

- • 18-month ROI through reduced pump energy consumption

- • Zero leakage incidents over 15km pipeline network

Maintenance Protocols for Extended Service Life

Proactive monitoring strategies enhance system longevity:

- ▶ Ultrasonic thickness testing every 24 months

- ▶ Joint integrity assessments using phased array technology

- ▶ Chemical resistance validation through coupon sampling

Future Outlook for High-Pressure Fiberglass Piping Systems

The high-pressure fiberglass piping system market anticipates 6.8% CAGR through 2030, driven by advanced manufacturing techniques enabling 15% wall thickness reduction without compromising pressure ratings. Recent material breakthroughs allow 92% recyclability of decommissioned FRP components, positioning these systems as sustainable infrastructure solutions.

(high-pressure fiberglass piping system)

FAQS on high-pressure fiberglass piping system

Q: What are the key advantages of a high-pressure fiberglass piping system?

A: High-pressure fiberglass piping systems offer exceptional corrosion resistance, high strength-to-weight ratio, and durability in extreme environments. They are ideal for industrial applications requiring reliable performance under pressure.

Q: How does a high-pressure FRP piping system compare to traditional metal piping?

A: Unlike metal piping, FRP piping systems resist rust, chemical degradation, and electrolytic corrosion. They also require less maintenance and have a longer service life in high-pressure applications.

Q: What industries commonly use high-pressure fiberglass pipe systems?

A: Industries like oil and gas, chemical processing, water treatment, and power generation rely on high-pressure fiberglass pipes due to their ability to handle corrosive fluids and extreme pressure conditions.

Q: Can high-pressure fiberglass pipes be customized for specific project needs?

A: Yes, FRP piping systems can be tailored in diameter, wall thickness, and resin formulations to meet specific pressure ratings, temperature ranges, and chemical exposure requirements.

Q: What installation considerations apply to FRP piping systems under high pressure?

A: Proper joint alignment, surface preparation, and use of compatible adhesives are critical. Regular inspection for leaks and adherence to manufacturer guidelines ensure optimal performance in high-pressure setups.

Latest news

-

High-Pressure Fiberglass Piping Systems Durable & Corrosion-Resistant FRP SolutionsNewsMay.20,2025

-

Fiberglass Reinforced Plastic Pipes Corrosion-Resistant & DurableNewsMay.20,2025

-

GRP Duct Systems Corrosion-Resistant & Durable SolutionsNewsMay.20,2025

-

Fiberglass Reinforced Plastic Pipes High-Strength & Corrosion-ResistantNewsMay.19,2025

-

Boost Data Speed Utilize RTRP Protocol for Efficient TransmissionNewsMay.19,2025

-

High-Performance Rock Drill Rod for MF Bits Mining & ConstructionNewsMay.18,2025