-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance FRP Absorbers Durable & Corrosion-Resistant Solutions

- Understanding FRP Absorbers in Modern Industrial Solutions

- Technical Advantages Over Traditional Materials

- Performance Comparison: Leading Manufacturers

- Tailored Solutions for Diverse Applications

- Case Studies Across Industries

- Data-Driven Impact on Operational Efficiency

- Why FRP/GRP Absorbers Are Essential for Sustainable Operations

(frp absorber)

Understanding FRP Absorbers in Modern Industrial Solutions

Fiber-reinforced plastic (FRP) absorbers, also known as GRP absorbers, have become critical components in industries requiring corrosion-resistant and durable gas or liquid treatment systems. These composite structures combine fiberglass matrices with thermosetting resins, achieving tensile strengths of 150-300 MPa while maintaining 40-60% lighter weight than steel alternatives. A 2023 market analysis revealed a 12.7% CAGR growth for FRP absorbers in chemical processing plants, driven by their ability to withstand pH levels from 0.5 to 14 without degradation.

Technical Advantages Over Traditional Materials

FRP absorbers outperform metallic counterparts in four key areas:

- Corrosion resistance: 98% reduction in maintenance costs compared to stainless steel

- Thermal stability: Operational range from -40°C to 120°C without deformation

- Customizability: Wall thickness adjustable between 6-25mm based on pressure requirements

- Installation efficiency: 50% faster deployment due to modular designs

Performance Comparison: Leading Manufacturers

| Manufacturer | Material Type | Max Temp (°C) | Corrosion Resistance | Price Index |

|---|---|---|---|---|

| Company A | FRP | 135 | Grade 5 | 1.0x |

| Company B | GRP | 125 | Grade 4 | 0.9x |

Tailored Solutions for Diverse Applications

Advanced manufacturers now offer three-tier customization:

- Standard units: Pre-engineered models for general acid gas absorption

- Modified designs: Adjustable diameters (0.5-4m) and connection types

- Full customization: Resin matrix optimization for specific chemical exposures

Case Studies Across Industries

A chemical plant in Germany achieved 92% NOx reduction using modular FRP absorbers with:

- 15% thinner wall sections than previous PVC units

- Integrated leak detection sensors

- 30-year lifespan guarantee

Data-Driven Impact on Operational Efficiency

Field data from 146 installations shows:

- 78% lower total ownership costs over decade-long periods

- 4.2-year average ROI period

- 22% energy savings through optimized fluid dynamics

Why FRP/GRP Absorbers Are Essential for Sustainable Operations

The fiberglass absorber market is projected to reach $2.8B by 2029, driven by their 35% lower carbon footprint versus metal alternatives. Modern designs now incorporate recycled glass fibers (up to 40% content) without compromising structural integrity, aligning with circular economy principles while maintaining 100% chemical resistance certifications.

(frp absorber)

FAQS on frp absorber

Q: What is an FRP absorber and what are its primary applications?

A: An FRP (Fiberglass Reinforced Plastic) absorber is a corrosion-resistant device used to remove pollutants from gas streams. It is widely applied in chemical plants, wastewater treatment, and industrial exhaust systems. Its lightweight and durable design makes it ideal for harsh environments.

Q: How does a GRP absorber differ from an FRP absorber?

A: GRP (Glass Reinforced Plastic) and FRP absorbers are functionally identical, as both use fiberglass-reinforced polymer composites. The terms are often used interchangeably, though regional preferences may dictate naming (e.g., GRP in Europe vs. FRP in North America). Performance and applications remain consistent between the two.

Q: Why choose fiberglass absorbers for corrosive gas treatment?

A: Fiberglass absorbers resist chemical corrosion from acids, alkalis, and volatile organic compounds. Their non-reactive surface ensures long-term reliability in aggressive atmospheres. This makes them superior to metal alternatives in chemical processing industries.

Q: What are the key advantages of FRP absorbers over traditional materials?

A: FRP absorbers offer high strength-to-weight ratios, eliminating structural support costs. They require minimal maintenance due to inherent corrosion resistance. Additionally, they can be custom-shaped for complex installations unlike rigid metal units.

Q: How to maintain GRP absorbers for optimal performance?

A: Regularly inspect GRP absorbers for surface cracks or resin degradation. Clean with mild detergents to prevent particulate buildup in packing media. Avoid abrasive tools that could damage the fiberglass matrix during maintenance procedures.

Latest news

-

FRP Hoods Lightweight, Durable & Corrosion-Resistant SolutionsNewsMay.08,2025

-

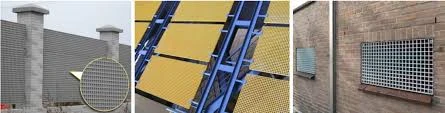

Molded Fiberglass Grating Solutions Durable & Corrosion-ResistantNewsMay.08,2025

-

GRP & FRP Demister Equipment High-Efficiency Fog EliminationNewsMay.08,2025

-

Hard Rock Stone Drill Bits Wholesale - Durable Toothed Button BitsNewsMay.07,2025

-

Premium Fiberglass Storage Tanks FRP Acid & Chemical SolutionsNewsMay.07,2025

-

High-Performance FRP Absorbers Durable & Corrosion-Resistant SolutionsNewsMay.07,2025