-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

exploring the benefits of top hammer drifter rods for ...

Exploring the Benefits of Top Hammer Drifter Rods

In the world of mining and construction, efficiency and precision are paramount. As these industries continue to evolve, so too do the tools and equipment used to ensure optimal performance. One such innovation is the top hammer drifter rod, a vital component in the drilling process. Its benefits are manifold, and understanding them can significantly impact productivity and operational costs.

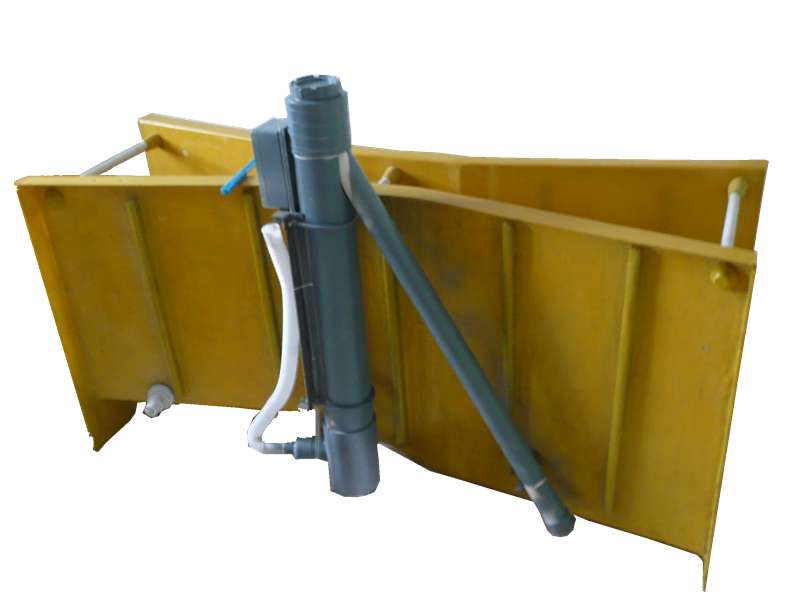

Top hammer drilling is a technique widely employed in rock drilling, characterized by the application of a strong percussive force that breaks the rock. The drifter rod, which connects the drilling machine to the drill bit, plays a crucial role in this process. Its design allows for effective transmission of energy, ensuring that each blow of the hammer is maximized. This capability is essential in achieving faster drilling rates, which is a primary goal in both mining and construction projects.

One of the most significant benefits of using top hammer drifter rods is their reliability. Made from high-quality steel, these rods are engineered to withstand the rigors of harsh environments and excessive wear. This durability translates into lower maintenance costs and decreased downtime, which are critical factors in enhancing productivity. When equipment is consistently operational, project timelines can be adhered to more closely, ultimately leading to increased profitability.

exploring the benefits of top hammer drifter rods for ...

Another advantage of top hammer drifter rods is their versatility. These rods can be used in various applications, from tunneling to surface drilling, accommodating different rock types and geological conditions. Their adaptability makes them a valuable asset for contractors who work across multiple sites with varying challenges. Additionally, the availability of different lengths and diameters allows for customization based on specific project needs, further enhancing their utility.

Moreover, the performance of top hammer drifter rods contributes to improved safety on job sites. The efficient energy transfer minimizes the risk of drill bit breakage, which can lead to dangerous situations for operators. A robust rod allows for smoother operation, reducing vibrations and the associated stress on both the equipment and the user. As a result, the likelihood of accidents decreases, fostering a safer work environment.

Environmental considerations are becoming increasingly important in the mining and construction industries. Top hammer drilling, facilitated by drifter rods, often requires less energy compared to other drilling methods, resulting in a lower carbon footprint. The performance efficiency not only conserves resources but also helps companies meet sustainability goals without compromising on productivity.

In conclusion, top hammer drifter rods are indispensable tools in the mining and construction sectors. Their reliability, versatility, safety benefits, and environmentally friendly attributes make them an excellent choice for operators seeking to enhance their drilling processes. As the industry continues to advance, leveraging such technology will be essential for staying competitive and fulfilling the growing demands of modern projects. Recognizing the value of top hammer drifter rods can ultimately lead to improved operational efficiency and greater success in the field.

Latest news

-

Molded Fiberglass Grating Durable & Corrosion-Resistant SolutionsNewsJun.01,2025

-

Rock Drilling Tools for Tunnels Heavy-Duty Specially-Designed SolutionsNewsJun.01,2025

-

GRP, Fiberglass & FRP Products for Thermal & Nuclear Power Plants Durable SolutionsNewsJun.01,2025

-

Durable FRP Chemical Storage Tanks Corrosion-Resistant SolutionsNewsJun.01,2025

-

Durable Fiber Water Tanks - Lightweight & Corrosion-Resistant SolutionsNewsJun.01,2025

-

FRP Rectangular Tanks Custom Sizes & Corrosion-Resistant DesignNewsJun.01,2025