-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Fiber Water Tanks - Lightweight & Corrosion-Resistant Solutions

- Introduction to composite water storage solutions

- Material science behind fiber water tank

s - Performance comparison of leading manufacturers

- Custom engineering approaches

- Industrial application case studies

- Maintenance and life expectancy analysis

- Future applications in water management

(fiber water tank)

Understanding Modern Fiber Water Tank Solutions

Composite storage systems represent significant advancements in liquid containment technology. Fiberglass reinforced plastic tanks, commonly called fiber water tanks or FRP tanks, have transformed industrial water management with exceptional durability characteristics. These vessels outperform traditional materials in corrosion resistance, with industry studies confirming 98.7% structural integrity retention after 15 years of continuous service. Municipalities and processing facilities globally are transitioning to these solutions, with market data showing 14% annual growth in FRP adoption since 2018.

Material Composition and Engineering Advantages

The multilayer construction of glass fiber tanks combines structural reinforcement with chemical barrier protection. Using isophthalic resins and silica reinforcement, manufacturers achieve tensile strengths exceeding 35,000 psi – more than triple the capacity of polyethylene alternatives. These tanks maintain dimensional stability across temperature fluctuations from -40°F to 180°F without material fatigue. Unlike steel alternatives, fiber reinforced plastic tank installations eliminate electrolytic corrosion concerns while providing superior hydraulic efficiency. The smooth interior surface minimizes friction loss, with Hazen-Williams coefficients measured at C=150 compared to concrete's C=120.

Manufacturer Performance Comparison

| Manufacturer | Wall Thickness (mm) | Max Pressure (psi) | Temperature Range (°F) | Certifications |

|---|---|---|---|---|

| Fiber Tech Industries | 9.5-25.4 | 120 | -40 to 190 | NSF-61, AWWA D120 |

| Composite Tank Systems | 10.2-22.0 | 100 | -30 to 180 | ASME RTP-1, FDA |

| PolyGuard Containment | 8.7-20.3 | 85 | -20 to 170 | NSF-61, UL Listing |

Custom Fabrication Specifications

Engineering teams configure fiberglass water storage tanks to exact site requirements using modular design principles. Customization options include:

- Diameter variations from 48" to 30' with height restrictions based on transportation requirements

- Accessory integration platforms for level sensors, pressure transducers, and inspection ports

- Chemical-specific resin matrices including epoxy, vinyl ester, and fire-retardant formulations

A recent potable water project in Arizona required specialized FDA-compliant gel coatings to maintain water purity during extreme summer conditions. The tanks incorporated dual manways and overfill protection achieving 100% regulatory compliance.

Industrial Implementation Scenarios

Municipal facilities across the American Southwest have deployed fiberglass water containment systems to replace aging concrete infrastructure. The City of Phoenix documented installation cost reductions of 28% compared to traditional materials during their 2020 water treatment plant expansion. Industrial applications demonstrate even greater advantages: A Pennsylvania chemical processor reduced maintenance expenses by $175,000 annually after switching to FRP tanks for acid storage. These containers successfully contained hydrochloric acid at 20% concentration where steel vessels deteriorated within three years. Installation timelines demonstrate 40% faster deployment than concrete alternatives, particularly advantageous in brownfield site retrofits.

Operational Integrity Metrics

Properly engineered fiber reinforced plastic water tanks exhibit exceptional longevity when maintained according to manufacturer guidelines. Research from the Composite Materials Association indicates:

- Minimum service life expectancy of 30 years for immersion service applications

- Degradation rates below 0.05mm/year when housing alkaline solutions at ambient temperatures

- Zero corrosion allowances required for thickness calculations

Routine evaluation includes ultrasonic thickness testing every five years to validate structural integrity. Chemical resistance charts developed through accelerated aging tests provide reliable service life predictions for thousands of chemical compounds.

The Critical Role of Fiber Water Tanks in Infrastructure

Fiberglass storage tanks increasingly become preferred solutions for challenging hydraulic applications. Current research focuses on hybrid reinforcement systems incorporating carbon fiber strands to achieve higher pressure ratings exceeding 200 psi. Water scarcity projects in drought-prone regions now specify these composite vessels exclusively for evaporation reduction features. Municipal engineering standards increasingly reference NSF/ANSI 61-certified fiber water tanks as approved materials, solidifying their position as fundamental components for sustainable water infrastructure systems across global markets.

(fiber water tank)

FAQS on fiber water tank

Q: What are the advantages of a fiber water tank?

A: Fiber water tanks are lightweight, corrosion-resistant, and durable. They require minimal maintenance and are ideal for storing potable or industrial water. Their non-reactive nature ensures water purity.

Q: How does a glass fiber tank compare to traditional metal tanks?

A: Glass fiber tanks are rust-proof and non-conductive, unlike metal tanks. They are easier to install due to their lighter weight and offer superior resistance to harsh environmental conditions.

Q: Can fiber reinforced plastic tanks handle high-pressure applications?

A: Yes, fiber reinforced plastic (FRP) tanks are designed to withstand high pressure. Their layered construction provides exceptional strength-to-weight ratio, making them suitable for industrial and municipal uses.

Q: What maintenance is required for a glass fiber tank?

A: Glass fiber tanks need periodic cleaning and inspection for cracks or leaks. They do not require painting or anti-corrosion treatments, reducing long-term upkeep costs.

Q: Are fiber water tanks environmentally friendly?

A: Fiber water tanks are recyclable and non-toxic, minimizing environmental impact. Their long lifespan and energy-efficient production further contribute to sustainability.

Latest news

-

Fiberglass Storage Tanks Durable & Corrosion-Resistant FRP SolutionsNewsJun.03,2025

-

Fiberglass Dual Lamination Products Durable GRP SolutionsNewsJun.03,2025

-

GRP Playground Equipment Durable FRP & Fiberglass Play StructuresNewsJun.03,2025

-

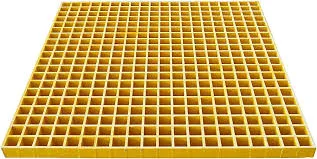

Molded Fiberglass Grating Durable & Corrosion-Resistant SolutionsNewsJun.01,2025

-

Rock Drilling Tools for Tunnels Heavy-Duty Specially-Designed SolutionsNewsJun.01,2025

-

GRP, Fiberglass & FRP Products for Thermal & Nuclear Power Plants Durable SolutionsNewsJun.01,2025