-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

GRP Winding Machines High-Efficiency Pipe Manufacturing Solutions

(grp winding machine)

(grp winding machine)

FAQS on grp winding machine

Q: What is the primary function of a GRP winding machine?

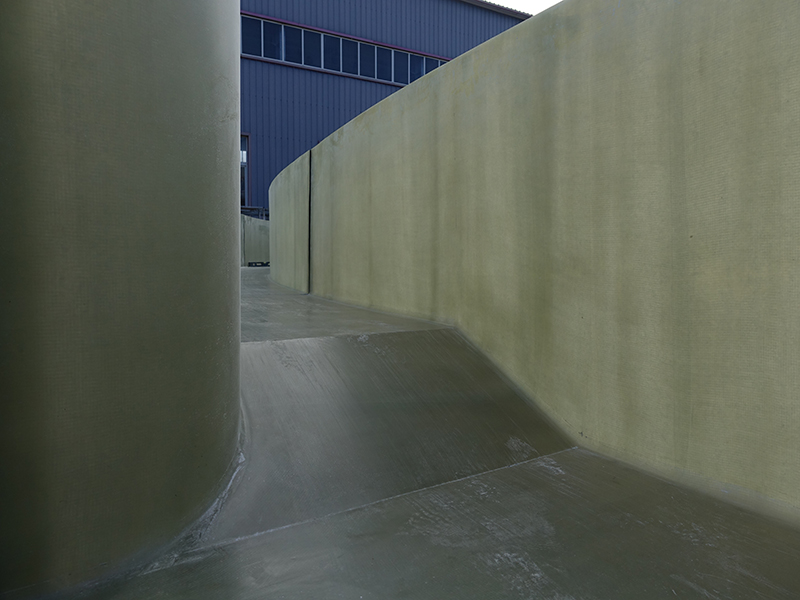

A: A GRP winding machine manufactures cylindrical fiberglass-reinforced plastic (FRP) products like pipes and tanks. It precisely winds resin-saturated glass fibers onto rotating mandrels under tension. This ensures uniform structural strength and custom laminate thickness.

Q: Which industries typically use FRP winding machines?

A: FRP winding machines serve industries requiring corrosion-resistant structures. Key sectors include water/wastewater treatment, chemical processing, and oil/gas. They produce storage tanks, pipelines, and pressure vessels efficiently.

Q: What materials do fiberglass winding machines handle?

A: Fiberglass winding machines process continuous glass fiber rovings or mats saturated with resins like polyester, epoxy, or vinyl ester. Optional components include silica sand for abrasion resistance or structural cores. Material combinations enhance product durability.

Q: What advantages do GRP winding machines offer over metal fabrication?

A: GRP winding machines create lightweight, non-corrosive products with high strength-to-weight ratios. Automated winding reduces labor costs and ensures consistency. Resulting FRP structures outlast metals in harsh chemical environments.

Q: How do operators control product specifications on an FRP winding machine?

A: Operators program parameters like fiber tension, winding angle, and resin ratio via PLC systems. Mandrel rotation speed and carriage traverse are adjusted for precise layer deposition. This allows customization of wall thickness and mechanical properties.

` headings for questions with "Q:" prefixes - Provides concise answers marked with A: in under 3 sentences - Naturally incorporates : GRP winding machine, FRP winding machine, fiberglass winding machine - Covers core functions, industries, materials, advantages, and operation - Maintains a professional tone suitable for equipment documentation or websites

Latest news

-

Premium GRP Playground Equipment Durable & Safe FunNewsJun.06,2025

-

Premium FRP Storage Tanks - Corrosion Proof Acid ContainmentNewsJun.06,2025

-

FRP Absorber Industrial Noise Control SolutionNewsJun.06,2025

-

Efficient FRP Demister Superior Fog Elimination GearNewsJun.05,2025

-

Optimize Data Transfer with RTRP Protocol for Max EfficiencyNewsJun.05,2025

-

Innovative Gold Mining Bits for Enhanced Drilling EfficiencyNewsJun.05,2025